Feb . 10, 2025 10:24

Back to list

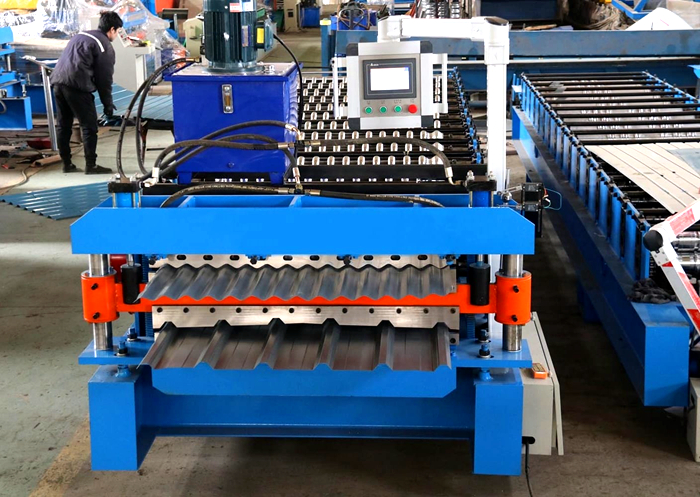

US Metal Roofing Ag and R panel Roll Former

In the bustling landscape of modern manufacturing, the roll forming machine emerges as an indispensable asset, particularly in steel processing. This technologically advanced apparatus is pivotal for industries that demand high precision, efficiency, and sustainability. With a surge in global steel production, understanding the intricacies of roll forming machines becomes crucial for businesses aiming to leverage high-quality steel products.

Real-world experience with roll forming machines has demonstrated their reliability and durability. Having evolved from basic manual models to sophisticated CNC-controlled systems, these machines have a proven track record for high-volume production with minimal maintenance. Companies investing in high-quality roll forming machinery can expect long operational lifespans, reducing the frequency of costly replacements and equipment downtime. The success of a roll forming operation heavily relies on the expertise of its operators and the quality of its machinery. Expert operators are adept at configuring the rollers, aligning the equipment, and troubleshooting any operational hiccups efficiently. This expertise guarantees optimized performance and maximal utilization of the steel material, ensuring each batch meets stringent industry standards. Trust in roll forming machines also stems from their adaptability to a wide range of steel grades. Whether working with galvanized steel, stainless steel, or high-strength steel variants, these machines can be precisely calibrated to manage different material properties, ensuring optimal performance and high-quality output. This adaptability positions roll forming machines as versatile tools for industries that vary in operational demands. In conclusion, the roll forming machine for steel stands as a beacon of technological advancement and operational efficiency in manufacturing. Its blend of precision, efficiency, sustainability, and durability underlines its indispensable nature in industries relying on steel products. As steel production continues to skyrocket globally, the demand for proficient roll forming solutions is set to expand, offering immense opportunities for businesses equipped with the expertise and technology to harness their potential. Companies that align their operations with these advanced systems are not only positioned to thrive in competitive markets but also to lead with sustainability and innovation at the forefront.

Real-world experience with roll forming machines has demonstrated their reliability and durability. Having evolved from basic manual models to sophisticated CNC-controlled systems, these machines have a proven track record for high-volume production with minimal maintenance. Companies investing in high-quality roll forming machinery can expect long operational lifespans, reducing the frequency of costly replacements and equipment downtime. The success of a roll forming operation heavily relies on the expertise of its operators and the quality of its machinery. Expert operators are adept at configuring the rollers, aligning the equipment, and troubleshooting any operational hiccups efficiently. This expertise guarantees optimized performance and maximal utilization of the steel material, ensuring each batch meets stringent industry standards. Trust in roll forming machines also stems from their adaptability to a wide range of steel grades. Whether working with galvanized steel, stainless steel, or high-strength steel variants, these machines can be precisely calibrated to manage different material properties, ensuring optimal performance and high-quality output. This adaptability positions roll forming machines as versatile tools for industries that vary in operational demands. In conclusion, the roll forming machine for steel stands as a beacon of technological advancement and operational efficiency in manufacturing. Its blend of precision, efficiency, sustainability, and durability underlines its indispensable nature in industries relying on steel products. As steel production continues to skyrocket globally, the demand for proficient roll forming solutions is set to expand, offering immense opportunities for businesses equipped with the expertise and technology to harness their potential. Companies that align their operations with these advanced systems are not only positioned to thrive in competitive markets but also to lead with sustainability and innovation at the forefront.

Latest news

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025

Related Products