roll forming machine for sale company

The Rise of Roll Forming Machines A Valuable Asset for Manufacturers

In the evolving landscape of manufacturing, businesses are constantly seeking innovative solutions to enhance productivity and efficiency. One such solution that has garnered significant attention is the roll forming machine. This versatile piece of equipment has become essential for companies aiming to streamline their production processes and deliver high-quality products. As the demand for roll forming machines grows, many companies are now offering these machines for sale, catering to a variety of industries.

The Rise of Roll Forming Machines A Valuable Asset for Manufacturers

One of the primary advantages of roll forming machines is their ability to produce a uniform product over long runs. The technology ensures consistent quality, which is crucial in industries where precision is paramount. Furthermore, once a roll forming line is set up, it can operate at high speeds, significantly enhancing production rates. This rapid turnover enables businesses to meet growing market demands and maintain a competitive edge.

roll forming machine for sale company

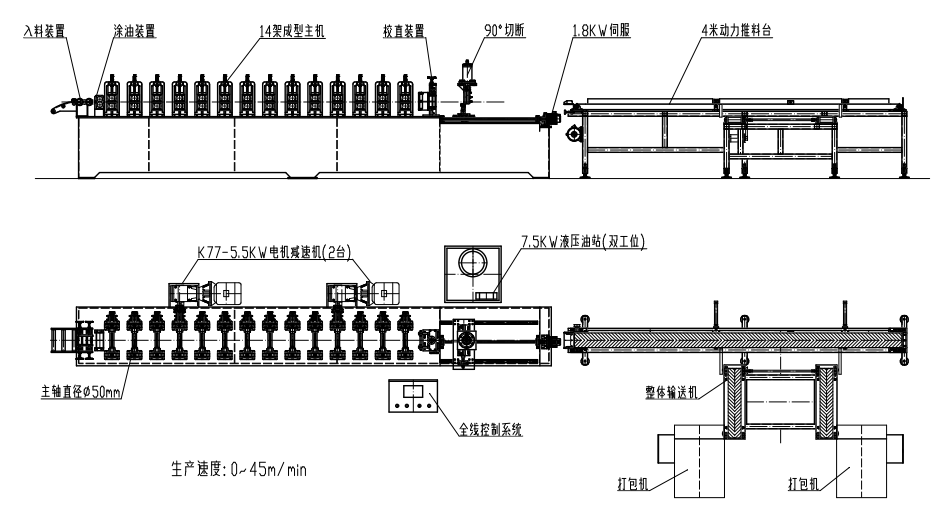

Additionally, modern roll forming machines come equipped with advanced features and programmable controls that enhance operational efficiency. These machines can be customized to suit specific production requirements, allowing companies to adapt their processes to different materials and designs. As technology advances, manufacturers are increasingly incorporating automation and robotics into their roll forming systems, resulting in reduced labor costs and improved overall efficiency.

When searching for roll forming machines for sale, it is essential for companies to consider several factors, including the machine's capacity, the materials it can handle, and its overall design. Investing in a high-quality roll forming machine can yield significant long-term benefits, including reduced maintenance costs and increased production capabilities. Additionally, collaborating with reputable manufacturers or suppliers can ensure access to the latest technology and support services, which are vital for successful implementation.

As sustainability becomes a focal point for many industries, the roll forming process also stands out for its eco-friendliness. The precision of the process minimizes waste, as manufacturers can utilize almost the entire strip of material, leaving little behind. Moreover, the materials used in roll forming, such as steel, are often recyclable, aligning with the growing industry trend towards sustainable manufacturing practices.

In conclusion, the roll forming machine represents a critical investment for manufacturers seeking to enhance their production processes. With the continual developments in technology and the increasing versatility of these machines, the future looks promising for the roll forming industry. Companies that recognize the value of these machines and explore their options in the market can position themselves advantageously for success. As more manufacturers embrace the benefits of roll forming, the demand for these machines for sale is likely to rise, creating opportunities for both suppliers and buyers in this dynamic field.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025