Roll Forming Equipment for Drywall Profile C Studs and Rails Manufacturing

The Role of Roll Forming Machines in Drywall Profile Production

In the construction industry, efficient and precise manufacturing processes are vital. Among the tools that revolutionized the production of building materials is the roll forming machine. Specifically, when it comes to creating drywall profiles, or perfil drywall parante, these machines play an indispensable role. This article will explore the functionalities, benefits, and applications of roll forming machines in the production of drywall profiles.

Understanding Roll Forming Machinery

Roll forming is a continuous bending operation in which metal sheets or strips are passed through a series of rollers to achieve a desired cross-section. The process typically involves a sequence of rollers arranged in a specific configuration to shape metal into the required form. This technique is known for its efficiency and precision, making it ideal for manufacturing components like drywall profiles.

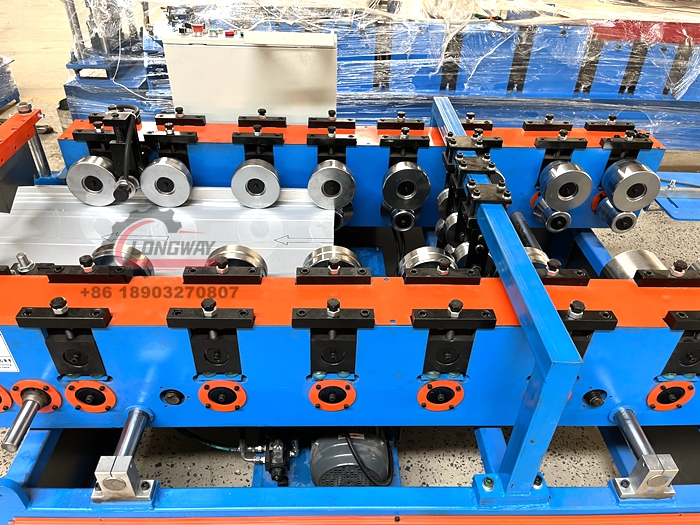

A roll forming machine consists of several essential components, including the feed mechanism, forming stations, and cutting stations. The feed mechanism ensures a constant supply of metal strips to the rollers, while the forming stations gradually shape the metal into the desired profile. The cutting station, usually positioned at the end of the machine, slices the finished profiles to the required lengths.

Advantages of Roll Forming for Drywall Profiles

1. High Production Rates Roll forming machines can operate continuously, producing large quantities of drywall profiles in a short amount of time. This efficiency is crucial for meeting the growing demands of construction projects.

2. Consistency and Precision One of the most significant advantages of roll forming is its ability to produce uniform profiles with precise dimensions. This consistency is vital in drywall construction, where the fit and finish of profiles greatly impact the overall quality of the installation.

3. Material Efficiency The roll forming process tends to generate minimal waste compared to other manufacturing methods. By utilizing the material effectively, companies can reduce costs and contribute to sustainability efforts.

roll forming machine for perfil drywall parante

4. Versatility in Design Roll forming machines are capable of producing a wide variety of profiles, allowing manufacturers to cater to various design requirements. Whether for wall studs, tracks, or other drywall components, the flexibility of roll forming accommodates diverse specifications.

5. Strength and Durability The metal profiles produced by roll forming are known for their structural integrity. The method enhances the strength of the resulting profiles, making them suitable for load-bearing applications in drywall installations.

Applications of Drywall Profiles

Drywall profiles, specifically parantes, are essential components in the construction of partitions, ceilings, and wall systems. These profiles serve as frameworks that support the drywall sheets, providing stability and structure to interior spaces. The use of roll-formed profiles ensures that these frameworks are durable, lightweight, and easy to install.

In addition to traditional drywall applications, roll-formed drywall profiles are gaining traction in modern architectural designs. Their ability to integrate seamlessly with various aesthetic features allows architects and builders to create innovative and functional spaces. Whether in residential, commercial, or industrial projects, the adaptability of drywall profiles enhances design possibilities.

Conclusion

In summary, the roll forming machine is a vital tool in the production of drywall profiles (perfil drywall parante). Its ability to produce high-quality, consistent, and efficient profiles has transformed the way drywall systems are constructed. As the construction industry continues to evolve and embrace new technologies, roll forming machines stand out for their efficiency, versatility, and reliability.

The growing demand for sustainable and efficient building practices ensures that roll forming will remain a crucial component of drywall manufacturing. As builders and manufacturers recognize the benefits of using roll-formed components, the future of drywall construction looks promising, characterized by improved quality, reduced waste, and innovative design solutions. In this context, integrating roll forming technology into production processes is not just an option; it is a necessity for staying competitive in the dynamic construction market.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025