Roll Forming Equipment Tailored for the Colombian Market and Its Unique Demands

Roll Forming Machine for Colombia Revolutionizing the Metal Processing Industry

In recent years, Colombia has emerged as a significant player in the South American manufacturing sector. With its strategic location, growing infrastructure, and increasing industrialization, the country is ripe for technological advancements that can enhance productivity and quality in manufacturing processes. One such innovation is the roll forming machine, which is revolutionizing the metal processing industry in Colombia. This article explores the importance of roll forming machines, their advantages, and how they are transforming the landscape of metal fabrication in Colombia.

What is a Roll Forming Machine?

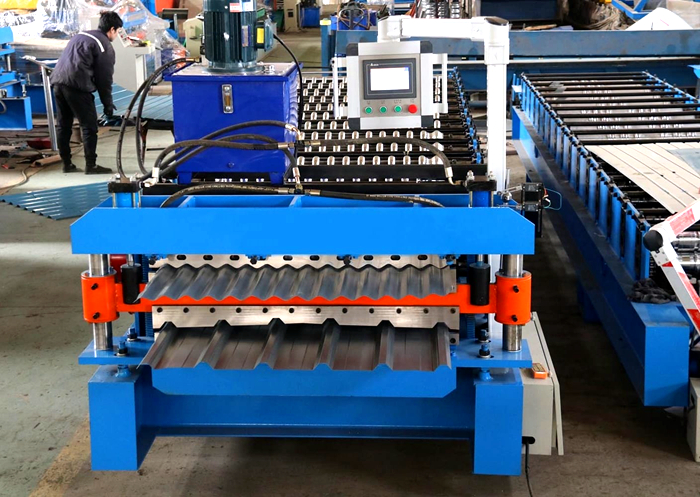

A roll forming machine is a type of equipment used to shape metal sheets into desired profiles by passing them through a series of rollers. The machine gradually bends the metal into the specified shape, which can range from simple tracks to complex shapes used in construction, automotive parts, and various other applications. This process is highly efficient and produces consistent, high-quality products that meet the demanding standards of various industries.

Advantages of Roll Forming Technology

1. High Efficiency Roll forming machines operate continuously, which means they can produce large quantities of products with minimal downtime. This efficiency is crucial for manufacturers in Colombia looking to fulfill increasing market demands without sacrificing quality.

2. Consistency and Precision One of the standout features of roll forming is its ability to produce precise and consistent profiles. This consistency is essential in industries such as construction and automotive, where the integrity of the components is critical. With roll forming technology, manufacturers can ensure that every piece meets exact specifications.

3. Material Savings The roll forming process is designed to minimize waste. Unlike other fabrication methods, roll forming utilizes the entire sheet of metal, which reduces material waste and lowers overall production costs. This environmentally friendly aspect aligns with the growing emphasis on sustainable practices within the Colombian manufacturing sector.

roll forming machine for colombia

4. Versatility Roll forming machines can be customized to produce a wide variety of shapes and sizes. This adaptability allows manufacturers in Colombia to cater to various sectors, from construction to electronics, and to quickly shift production lines in response to market demands.

5. Strength and Durability The final products created by roll forming machines are known for their strength and durability. The process of cold rolling, combined with the quality of the materials used, results in components that can withstand rigorous conditions, making them ideal for construction and heavy-duty applications.

Impact on the Colombian Market

As Colombia continues to modernize its manufacturing capabilities, the introduction of roll forming machines represents a significant step forward. These machines are already being integrated into various industries, including construction, automotive, and appliances. The ability to produce high-quality, durable components locally not only reduces reliance on imports but also boosts the local economy by creating jobs and fostering technological innovation.

Moreover, the adoption of roll forming technology aligns with Colombia’s goals for economic development and industrialization. By investing in modern manufacturing technologies, the country can enhance its global competitiveness and attract foreign investments. Additionally, as Colombian manufacturers become more efficient, they can offer competitive pricing, further establishing Colombia as a manufacturing hub in South America.

Conclusion

In conclusion, roll forming machines are poised to play a crucial role in the future of Colombia’s metal processing industry. With their many advantages, including efficiency, precision, and material savings, these machines are transforming the way manufacturers produce metal components. As Colombia continues its journey towards industrialization, the embrace of innovative technologies like roll forming will undoubtedly enhance its manufacturing landscape, ensuring sustainable growth and development. As the market evolves, the commitment to quality and efficiency will remain essential, and roll forming technology will be at the forefront of this transformation, enabling Colombian manufacturers to thrive in an increasingly competitive global market.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025