roll forming machine exporter

Roll Forming Machine Exporter A Global Perspective

The roll forming machine has become an integral part of the manufacturing industry, known for its efficiency and versatility in producing metal parts with consistent quality. As the global demand for rolled products rises, the role of roll forming machine exporters has become increasingly crucial. These exporters not only facilitate the international trade of machinery but also contribute to the development of manufacturing sectors in various countries.

Understanding Roll Forming Technology

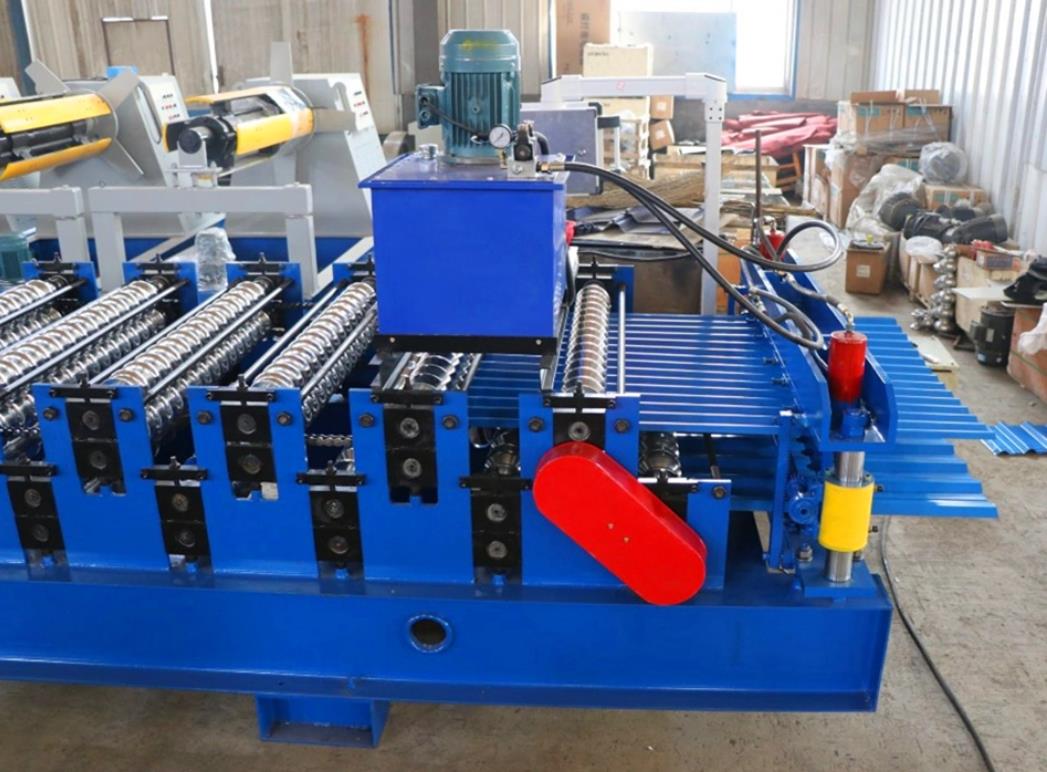

Roll forming is a continuous bending operation in which a long strip of metal, usually coiled steel, is passed through a series of rollers to achieve the desired cross-sectional profile. This process is particularly favored for producing shapes that maintain high dimensional accuracy and excellent surface finish. Common applications include manufacturing metal roofing, wall panels, C and Z purlins, and automotive components, making roll forming machines vital in many industries.

The machines themselves vary in complexity and can be tailored to meet the specific production needs of different sectors. Advanced roll forming machines incorporate features such as programmable controls, automatic cutting, and even integrated welding capabilities, allowing manufacturers to produce high volumes of products efficiently.

The Role of Exporters in the Industry

As manufacturers seek to upgrade their equipment or expand production capabilities, roll forming machine exporters play a pivotal role. These exporters facilitate access to advanced machinery that may not be available in local markets. By sourcing high-quality machines from countries known for their manufacturing excellence, such as Germany, Italy, and the USA, exporters ensure that industries worldwide benefit from state-of-the-art technology.

Moreover, roll forming machine exporters often provide essential support services, including installation, training, and maintenance. Their expertise ensures that local manufacturers can operate their new equipment effectively and safely, thus maximizing the return on investment. This support not only enhances the performance of the machines but also fosters a deeper understanding of roll forming technology among local engineers and operators.

roll forming machine exporter

Trends Influencing the Roll Forming Machine Market

Several trends are influencing the roll forming machine market, impacting both manufacturers and exporters. One of the most notable is the growing emphasis on sustainability and energy efficiency. Manufacturers are increasingly looking for equipment that minimizes waste and reduces energy consumption, leading to a demand for more eco-friendly roll forming machines. Exporters who adapt to this trend by offering energy-efficient models will have a competitive edge in the market.

Additionally, the rise of automation and Industry 4.0 technologies is transforming manufacturing processes. Exporters that integrate smart technology into their roll forming machines—such as IoT connectivity for real-time monitoring and data analytics—will appeal to a modern clientele looking for ways to enhance productivity and reduce operational costs.

Global Export Markets

The demand for roll forming machines is not limited to any single region. Emerging economies in Asia, such as India and Vietnam, are rapidly industrializing and experiencing significant growth in their construction and automotive sectors. Consequently, these countries present lucrative opportunities for roll forming machine exporters. Furthermore, the demand in developed markets, such as North America and Europe, continues to grow as existing manufacturers seek to upgrade their facilities and enhance their competitive edge.

Conclusion

The role of roll forming machine exporters is vital in the current global manufacturing landscape. By providing access to advanced technology and support services, they empower industries to improve production capabilities and drive economic growth. As trends such as sustainability, automation, and digital transformation take center stage, roll forming machine exporters must adapt to meet the evolving needs of their clients. As the demand for high-quality rolled products continues to grow, the opportunities for exporters are vast, making this sector an exciting arena for business development and international trade. The future of roll forming is bright, and those who navigate it effectively will play a key role in shaping the industry.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025