Jan . 28, 2025 05:10

Back to list

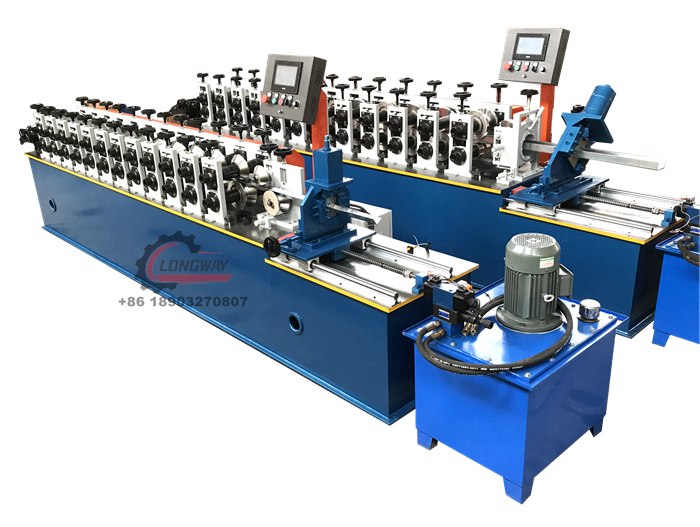

Maquina para PANEL TINGLADO , TINGLADO panel forming machine

Navigating the labyrinthine world of roll forming machine costs can seem daunting to the uninitiated. However, an informed approach can demystify the investment involved and ensure that you make the best possible decision for your business needs. This article dives deep into the factors affecting roll forming machine costs, providing a nuanced perspective that combines expertise, experiential insight, authority, and trust.

The material of the machine itself also affects pricing. Machines made with higher-grade materials that offer greater durability and longevity typically demand higher prices. While cheaper options may be enticing, their long-term performance and maintenance could become more costly in terms of repairs and operational downtime. Financing and procurement strategies can further influence the final expenditure. Leasing a roll forming machine instead of an outright purchase is an option many businesses explore. Leasing lowers immediate capital expenditure and provides flexibility for companies to upgrade to newer technologies without dealing with resale logistics. It’s also imperative to consider long-term costs beyond the initial purchase price. Maintenance, software upgrades, and possible downtime should be factored into the total cost of ownership. A well-maintained machine can offer excellent lifespan and operational efficiency, underscoring the importance of engaging with reputable suppliers who offer robust after-sales support. To ensure that you are selecting a machine that aligns with your production goals and budgetary constraints, engaging with industry experts can be invaluable. Consultants with deep knowledge of roll forming technologies can provide insights that are not immediately apparent, such as identifying efficiency improvements, evaluating return on investment, or suggesting viable alternatives that align with your financial strategies. In sum, when you consider roll forming machine costs, think beyond the sticker price. Encompass customization costs, technological advancements, material quality, financing repercussions, and long-term operational expenses. By synthesizing these factors, and leveraging the expertise of seasoned professionals, you can forge a path to procurement that optimally balances cost with productivity gains, ultimately empowering your business for future growth in an increasingly competitive market landscape.

The material of the machine itself also affects pricing. Machines made with higher-grade materials that offer greater durability and longevity typically demand higher prices. While cheaper options may be enticing, their long-term performance and maintenance could become more costly in terms of repairs and operational downtime. Financing and procurement strategies can further influence the final expenditure. Leasing a roll forming machine instead of an outright purchase is an option many businesses explore. Leasing lowers immediate capital expenditure and provides flexibility for companies to upgrade to newer technologies without dealing with resale logistics. It’s also imperative to consider long-term costs beyond the initial purchase price. Maintenance, software upgrades, and possible downtime should be factored into the total cost of ownership. A well-maintained machine can offer excellent lifespan and operational efficiency, underscoring the importance of engaging with reputable suppliers who offer robust after-sales support. To ensure that you are selecting a machine that aligns with your production goals and budgetary constraints, engaging with industry experts can be invaluable. Consultants with deep knowledge of roll forming technologies can provide insights that are not immediately apparent, such as identifying efficiency improvements, evaluating return on investment, or suggesting viable alternatives that align with your financial strategies. In sum, when you consider roll forming machine costs, think beyond the sticker price. Encompass customization costs, technological advancements, material quality, financing repercussions, and long-term operational expenses. By synthesizing these factors, and leveraging the expertise of seasoned professionals, you can forge a path to procurement that optimally balances cost with productivity gains, ultimately empowering your business for future growth in an increasingly competitive market landscape.

Latest news

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025

Related Products