Advanced Roll Forming Line Machinery for Efficient Metal Fabrication Process

Understanding Roll Forming Line Machines

Roll forming line machines are essential tools in the metalworking industry, particularly for producing high-quality, uniform profiles from metal strips. This continuous process utilizes a series of rollers to shape metal into desired forms, making it an economical and efficient solution for creating large quantities of components.

At the heart of the roll forming process is the roll forming line itself, which comprises several key components the uncoiler, the roll forming machine, the cutting mechanism, and the stacking unit. The uncoiler unwinds the metal coil, feeding it into the forming section. The roll forming machine consists of multiple pairs of rollers, each designed to gradually bend the metal strip into the required shape. The precision of these rollers is vital, as even the slightest misalignment can result in defects in the final product.

One of the significant advantages of roll forming line machines is their ability to produce complex shapes with tight tolerances. This makes them suitable for a wide range of applications, from automotive parts to construction materials. In the automotive industry, for instance, roll forming is used to manufacture components such as chassis, trim, and brackets, ensuring high strength and durability while minimizing weight.

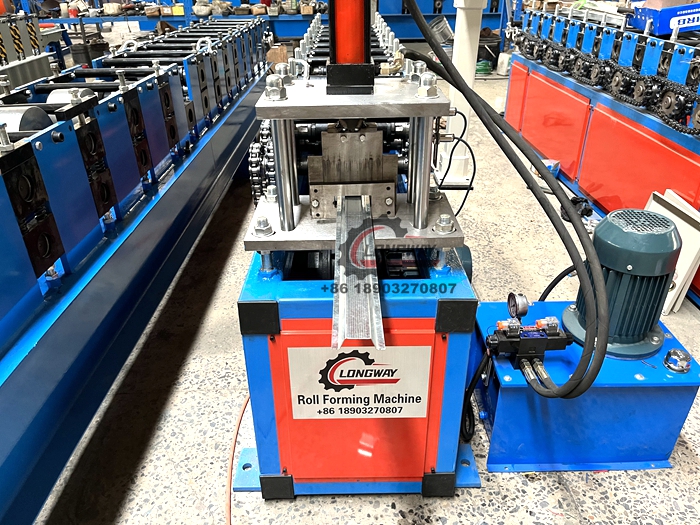

roll forming line machine

Additionally, roll forming lines can be integrated with various other technologies to enhance their capabilities. For example, some machines may feature automatic cutting tools that operate in tandem with the forming process, allowing for continuous production without the need for manual intervention. This integration not only increases efficiency but also significantly reduces production costs.

Maintenance is also a critical aspect of operating a roll forming line. Regular checks on the roller alignment, lubrication of moving parts, and inspection of the cutting mechanisms help ensure the machine operates smoothly. Preventative maintenance can significantly extend the lifespan of the equipment and improve product quality.

Environmental considerations are increasingly influencing the design of roll forming line machines. Many manufacturers are now seeking to reduce waste and energy consumption throughout the forming process. Innovations such as using lighter materials or optimizing the roller design for energy efficiency are helping to address these concerns.

In summary, roll forming line machines play a vital role in the manufacturing sector by offering a versatile, efficient way to produce metal profiles. Their ability to maintain high tolerances and adapt to various applications makes them invaluable for industries such as automotive, construction, and beyond. As technology continues to advance, the capabilities and efficiency of roll forming line machines will undoubtedly improve, driving further innovations in metal fabrication.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025