Roll Forming and Bending Machine Production Facility Overview and Capabilities

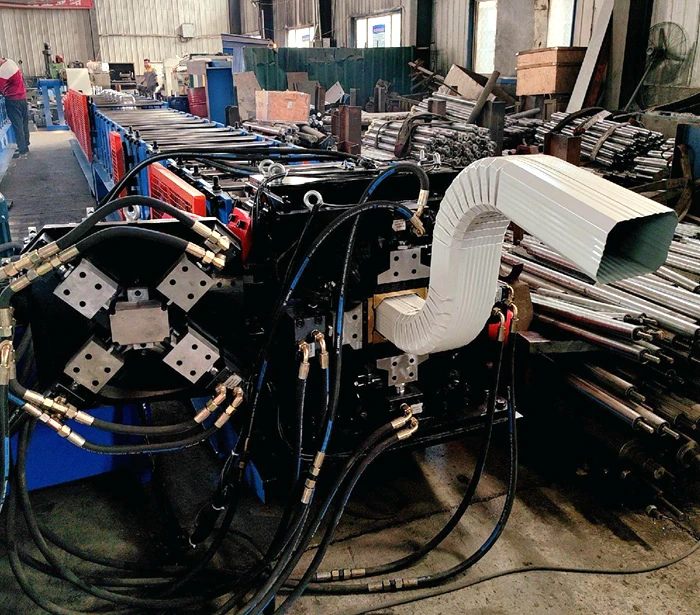

Roll Forming Bending Machines A Closer Look at the Factory

In the world of metalworking and fabrication, roll forming bending machines play a crucial role in shaping materials into intricate designs. These machines are integral to various industries, including construction, automotive, and aerospace, where precision and versatility are paramount. Understanding the production processes and innovations within a roll forming bending machine factory reveals the sophistication and technology involved in their creation.

What is Roll Forming?

Roll forming is a continuous process where sheet metal is gradually shaped into desired profiles using a series of rollers. This method is known for its ability to produce long lengths of consistent cross-sections, making it ideal for applications ranging from roofing panels to automotive frames. The bending aspect of these machines allows for the creation of complex curves and angles, further expanding the capabilities of roll forming.

The Manufacturing Process

The production of roll forming bending machines involves several stages, each requiring meticulous attention to detail and precision engineering. The first step is design, where engineers use advanced CAD software to create blueprints for the machinery. Various factors, including the material type, thickness, and the desired profile, influence the design process.

Once the design is complete, the manufacturing phase begins. High-quality materials, such as carbon steel and stainless steel, are sourced to ensure durability and performance. The components are then cut, shaped, and formed using high-precision machinery like CNC machines and laser cutters. This stage is critical, as the accuracy of these components directly affects the machine's performance.

After the components are fabricated, they undergo surface treatment processes such as welding, painting, or galvanizing. This not only enhances the aesthetic appeal of the machines but also increases their resistance to corrosion and wear. The assembly of the machine follows, where skilled technicians meticulously put together all parts, ensuring that every element fits perfectly.

Innovations in Roll Forming Technology

Modern roll forming bending machine factories are continually integrating the latest technologies to enhance production efficiency and machine capabilities. Automation is a significant trend, with many factories employing robotics to streamline the manufacturing process. Automated systems can handle repetitive tasks, reducing labor costs and minimizing the risk of human error.

roll forming bending machine factory

Additionally, the adoption of Industry 4.0 concepts has transformed how factories operate. Real-time monitoring and data analytics enable manufacturers to track machine performance, predict maintenance needs, and optimize production schedules. These innovations not only improve productivity but also contribute to cost savings and enhanced product quality.

Customization and Versatility

One of the standout features of roll forming bending machines is their ability to be customized for specific applications. Many factories offer tailored solutions, allowing clients to specify their requirements for unique profiles or production capacities. This flexibility is particularly beneficial in industries where custom parts are essential.

Furthermore, the versatility of roll forming bending machines allows for various materials to be processed, including aluminum, copper, and even specialty metals. This adaptability makes them suitable for a wide range of applications, from producing light gauge metal products to heavy-duty structural components.

Quality Control and Testing

To ensure that roll forming bending machines meet the highest standards, rigorous quality control processes are implemented throughout the manufacturing process. Each machine undergoes extensive testing and inspection before it leaves the factory. This includes checking dimensional accuracy, structural integrity, and operational efficiency.

Clients receive detailed documentation outlining the testing procedures and results, assuring them of the machine's reliability and performance capabilities.

Conclusion

The roll forming bending machine factory is a hub of innovation and engineering excellence. Through meticulous design and manufacturing processes, these factories produce machines that are essential for numerous industries. With ongoing advancements in technology and a focus on customization, the future of roll forming bending machines looks promising. As industries evolve and demands change, the factories behind these machines will continue to adapt, ensuring that they remain at the forefront of metal fabrication technology.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025