roll forming bending machine

Understanding Roll Forming Bending Machines

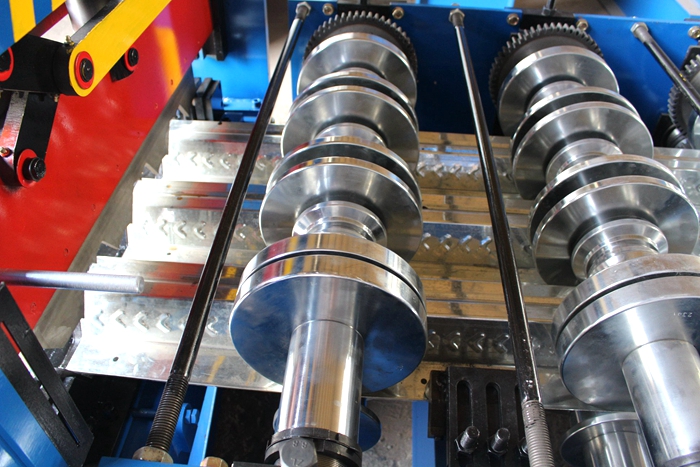

Roll forming bending machines are essential tools in the metalworking industry, known for their ability to efficiently produce a variety of shapes and profiles from metal sheets or strips. These machines function by continuously feeding a strip of metal through a series of rollers, which gradually shape the material into desired forms. This article delves into the operation, benefits, applications, and future of roll forming bending machines.

Operation of Roll Forming Bending Machines

The operational process of roll forming bending machines generally involves several key stages. First, the metal strip is fed into the machine, usually at a consistent width and thickness. As the material passes through the rollers, each roller in the series progressively alters the shape of the strip. Depending on the design setup, these rollers can bend, twist, or form the strip into various configurations.

The bending process typically utilizes a combination of rotary die and contouring methods. In rotary die bending, the part is clamped against a rotating die, which applies pressure to achieve the required bend angle. Conversely, contour bending involves employing a series of patterned rollers that can create more complex shapes with higher precision.

Benefits of Roll Forming Bending Machines

One of the primary advantages of roll forming bending machines is their efficiency. They are capable of producing long lengths of metal sections in a continuous process, thereby reducing production time and labor costs. This efficiency is particularly beneficial for high-volume production runs where speed and consistency are crucial.

Another significant benefit is the material savings associated with this technology. The process creates less waste compared to traditional metalworking methods. Additionally, the ability to use thinner gauge materials while still achieving robust designs allows manufacturers to reduce material costs.

Precision is another hallmark of roll forming bending machines. The use of automated controls ensures that the final product meets stringent specifications every time. This high level of accuracy minimizes the need for further processing or finishing, which can save both time and costs.

roll forming bending machine

Applications of Roll Forming Bending Machines

Roll forming bending machines are widely used across many industries, including automotive, construction, appliances, and furniture. In the automotive sector, they create various components such as frames, brackets, and support beams that require different bending angles and profiles for structural integrity.

In construction, roll forming bending machines are utilized to produce roofing and siding materials, which demand durability and aesthetic appeal. Furniture manufacturers also leverage these machines to create stylish and sturdy components that enhance product longevity.

Moreover, as industries evolve, the demand for custom shapes and designs increases. Roll forming bending machines can be adjusted to create bespoke profiles, making them invaluable for companies looking to differentiate their products in a competitive marketplace.

The Future of Roll Forming Bending Machines

As technology advances, the future of roll forming bending machines appears promising. The integration of automation and robotics into these machines is expected to further enhance precision and productivity. Additionally, innovations such as smart technology and data analytics could allow manufacturers to monitor and optimize production processes in real time.

Sustainability is also becoming a core focus in manufacturing. Roll forming bending machines that are energy-efficient and capable of using recycled materials will likely be at the forefront of this shift.

In conclusion, roll forming bending machines play a critical role in modern manufacturing processes, offering efficiency, precision, and versatility. As industries continue to innovate and evolve, these machines will undoubtedly adapt, providing capabilities that meet the changing needs of the market and contributing to a more sustainable future.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025