Mar . 05, 2025 07:42

Back to list

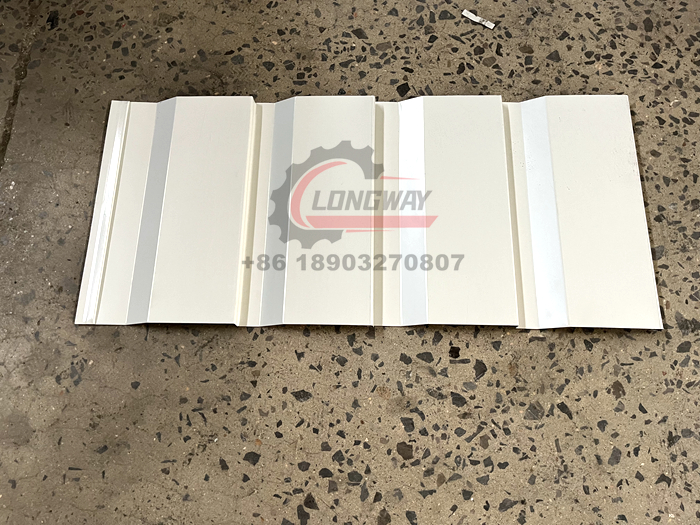

roll forming bending machine

In the vast landscape of modern manufacturing, the roll forming bending machine stands as a paragon of innovation and efficiency, particularly for industries seeking precision in shaping metal components. These machines are not mere tools; they are the linchpin in the assembly lines, providing unparalleled accuracy, repeatability, and productivity. As businesses worldwide strive for superior product quality, the role of roll forming bending machines has become progressively vital.

Beyond precision, the economic benefits of roll forming bending machines are significant. By minimizing material wastage and expediting production rates, these machines can drastically lower operational costs. Businesses can thus achieve higher output with reduced labor and material expenses, optimizing resource allocation and enhancing bottom-line profitability. Furthermore, the development of automated roll forming systems has propelled productivity to unprecedented levels, ensuring rapid turnaround times and maximizing throughput. From a sustainability perspective, roll forming bending machines are integral to the green manufacturing paradigm. With increasing emphasis on eco-friendly practices, these machines provide a means to conserve resources by reducing scrap metal generation and energy consumption. The precision and efficiency inherent in roll forming processes contribute to lowering the carbon footprint, aligning manufacturing operations with global sustainability goals. As industries continue to evolve, so do the technologies that underpin them. Today's roll forming bending machines are equipped with state-of-the-art control systems and software, enabling advanced features such as real-time monitoring, fault detection, and adaptive control. These innovations enhance machine reliability and efficiency, providing operators with the tools required to maintain optimal performance even in the most demanding production settings. In conclusion, the roll forming bending machine is more than a manufacturing apparatus; it embodies the intersection of precision engineering and sustainable industrial practices. Its profound impact on product quality, cost-efficiency, and environmental sustainability highlights its significance in the contemporary industrial landscape. Companies embracing this technology not only enhance their production capabilities but also position themselves as leaders in innovation, efficiency, and responsible manufacturing practices. As the demand for high-quality, sustainable production intensifies, the roll forming bending machine will undoubtedly remain a cornerstone of modern manufacturing excellence.

Beyond precision, the economic benefits of roll forming bending machines are significant. By minimizing material wastage and expediting production rates, these machines can drastically lower operational costs. Businesses can thus achieve higher output with reduced labor and material expenses, optimizing resource allocation and enhancing bottom-line profitability. Furthermore, the development of automated roll forming systems has propelled productivity to unprecedented levels, ensuring rapid turnaround times and maximizing throughput. From a sustainability perspective, roll forming bending machines are integral to the green manufacturing paradigm. With increasing emphasis on eco-friendly practices, these machines provide a means to conserve resources by reducing scrap metal generation and energy consumption. The precision and efficiency inherent in roll forming processes contribute to lowering the carbon footprint, aligning manufacturing operations with global sustainability goals. As industries continue to evolve, so do the technologies that underpin them. Today's roll forming bending machines are equipped with state-of-the-art control systems and software, enabling advanced features such as real-time monitoring, fault detection, and adaptive control. These innovations enhance machine reliability and efficiency, providing operators with the tools required to maintain optimal performance even in the most demanding production settings. In conclusion, the roll forming bending machine is more than a manufacturing apparatus; it embodies the intersection of precision engineering and sustainable industrial practices. Its profound impact on product quality, cost-efficiency, and environmental sustainability highlights its significance in the contemporary industrial landscape. Companies embracing this technology not only enhance their production capabilities but also position themselves as leaders in innovation, efficiency, and responsible manufacturing practices. As the demand for high-quality, sustainable production intensifies, the roll forming bending machine will undoubtedly remain a cornerstone of modern manufacturing excellence.

Latest news

-

Top Metal Roofing Machine ManufacturersNewsAug.04, 2025

-

Production Line with a Gutter Forming Machine for SaleNewsAug.04, 2025

-

Production Capacity with a Purlin Machine for SaleNewsAug.04, 2025

-

Exploring Roofing Sheets Manufacturing Machine PriceNewsAug.04, 2025

-

Drywall Roll Forming Machine for SaleNewsAug.04, 2025

-

Best Roof Panel Machine for SaleNewsAug.04, 2025

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

Related Products