roll former manufacturers factory

Exploring the Role of Roll Former Manufacturers in Modern Industry

In the fast-paced world of manufacturing, the demand for precision and efficiency has led to a significant evolution in production processes. One key player in this evolution is the roll former, a specialized machine that shapes metal sheets into desired profiles for various applications, from roofing materials to structural components. As industries continue to grow and diversify, the role of roll former manufacturers has become increasingly important, providing essential machinery that underpins modern manufacturing.

Understanding Roll Forming

Roll forming is a continuous bending process that involves feeding strips of metal through a series of rollers. These rollers shape the metal into a specific cross-section while maintaining its length. The process is highly efficient, enabling manufacturers to produce high volumes of products with consistent quality and precision. Roll formed products are ubiquitous in industries such as construction, automotive, and appliance manufacturing, highlighting the importance of reliable roll forming equipment.

The Factory Setup of Roll Former Manufacturers

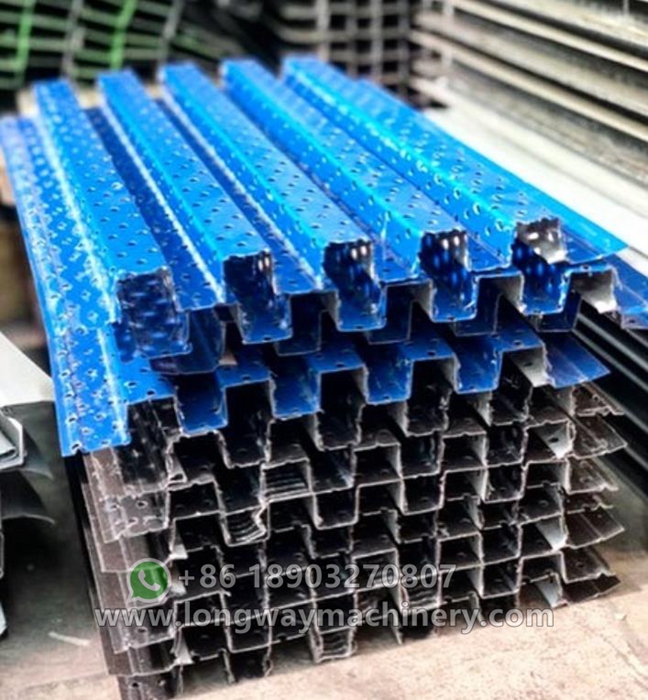

The factories of roll former manufacturers are intricate operations designed to optimize production efficiency while maintaining rigorous quality control. Modern roll forming facilities are equipped with advanced technologies, including automated systems, computer numerical control (CNC), and high-speed machinery. These technologies not only increase the productivity of the manufacturing process but also enhance the precision and consistency of the final products.

Typically, a roll former manufacturer’s factory will include areas for metal coil storage, roll forming lines, assembly areas, and finishing processes. Quality assurance laboratories are also integral to the operation, where engineers conduct rigorous tests on the finished products to ensure they meet industry standards and customer specifications.

Customization and Innovation

roll former manufacturers factory

One of the most significant aspects of roll former manufacturers is their ability to provide customized solutions to meet specific client needs. Each industry has unique requirements, and roll former manufacturers work closely with clients to design and produce bespoke machinery and tooling. This level of customization not only enhances product functionality but also contributes to operational efficiencies.

In addition to customization, innovation plays a crucial role in the operations of roll former manufacturers. As markets evolve, manufacturers are continually investing in research and development to improve their products and processes. Innovations such as lightweight materials, advanced coatings, and improved energy efficiency are becoming standard in roll forming design, enabling manufacturers to remain competitive in a global market.

Sustainability in Roll Forming

In recent years, sustainability has emerged as a critical consideration in manufacturing processes, and roll former manufacturers are no exception. Many factories are adopting eco-friendly practices, such as reducing waste, recycling scrap materials, and utilizing energy-efficient machinery. By implementing sustainable practices, companies not only align with global efforts to reduce environmental impact but also appeal to increasingly eco-conscious consumers.

Moreover, roll formed products often contribute to sustainability. For example, metal roofing systems can offer better energy efficiency, leading to reduced heating and cooling costs for buildings. Roll formed components are also frequently made from recyclable materials, adding an extra layer of eco-friendliness to the manufacturing process.

Conclusion

The significance of roll former manufacturers cannot be overstated in the context of modern industry. From their advanced manufacturing facilities and commitment to customization and innovation to their focus on sustainability, these manufacturers play a vital role in meeting the diverse needs of various sectors. As industries continue to evolve and prioritize efficiency and environmental responsibility, the contribution of roll former manufacturers to the global supply chain is set to become even more prominent. Embracing new technologies and sustainable practices will ensure that roll former manufacturers remain at the forefront of manufacturing innovation, driving the industry forward for years to come.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025