Innovative Roll Former Design for Advanced Volcometal Applications in Modern Manufacturing

Roll Former for Volcometal Parante A Revolution in Metal Forming Technology

In recent years, the demand for advanced metal forming technologies has surged, driven by the needs of various industries, from construction to automotive manufacturing. One of the standout innovations in this field is the roll former, particularly when tailored for processing products like Volcometal Parante. This technology not only enhances efficiency but also ensures that products meet stringent quality standards.

Understanding Roll Forming Technology

Roll forming is a continuous bending process in which strips of metal are passed through a series of rollers to achieve the desired cross-sectional shape. This method is renowned for its ability to produce long lengths of uniform sections with minimal waste. When applied to Volcometal Parante, a high-quality metal material known for its durability and versatility, the roll forming process becomes even more significant.

Volcometal Parante Characteristics and Applications

Volcometal Parante is a robust metal alloy widely used across various sectors due to its resistance to corrosion, excellent strength-to-weight ratio, and aesthetic appeal. These attributes make it suitable for a range of applications, from roofing sheets in construction to automotive components. The unique properties of Volcometal Parante demand precise and efficient manufacturing processes, which is where roll forming comes into play.

The Benefits of Using Roll Formers for Volcometal Parante

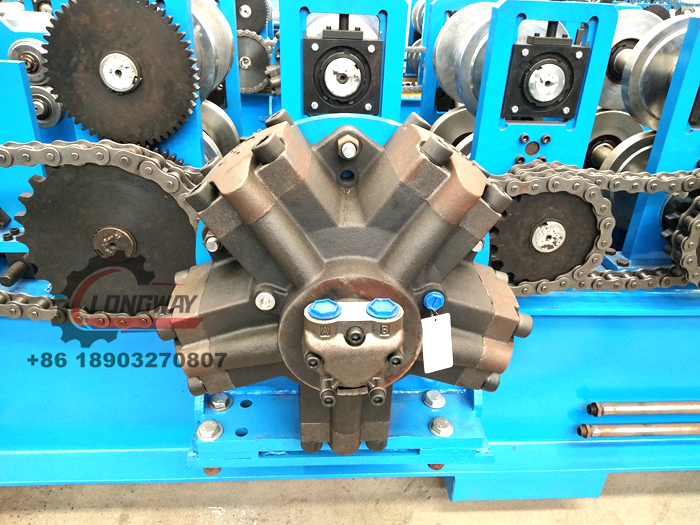

roll former for volcometal parante

1. Efficiency and Cost-Effectiveness The roll forming process is highly efficient, allowing manufacturers to produce large volumes of products quickly. This efficiency translates to lower production costs, making it an economically viable option for companies looking to maximize their profit margins while maintaining high-quality standards.

2. Consistent Quality With traditional metal forming methods, variations in product dimensions and quality can occur. Roll forming, however, maintains a high level of consistency in the output. This is particularly crucial for Volcometal Parante, as precise dimensions and uniformity are essential for applications such as structural components.

3. Complex Shapes and Customization Roll formers can easily be designed to create complex shapes that would be challenging to achieve with other methods. This flexibility allows manufacturers to innovate and customize products to meet specific customer needs, making roll forming a versatile choice for working with Volcometal Parante.

4. Reduced Waste One of the significant advantages of roll forming is the minimal waste produced during the manufacturing process. By utilizing a continuous feed of metal, companies can maximize material usage, which is especially important given the rising costs of raw materials.

The Future of Roll Forming with Volcometal Parante

As industries continue to evolve, the need for advanced manufacturing solutions becomes more pronounced. The integration of roll forming technology for materials like Volcometal Parante is set to play a crucial role in meeting these demands. With ongoing advancements in automation and smart manufacturing, the roll former is likely to become an even more integral part of the metal forming landscape.

In conclusion, the roll former represents a significant advancement in the processing of materials such as Volcometal Parante. Its efficiency, consistency, and ability to produce complex shapes with minimal waste make it an invaluable tool for manufacturers. As the market moves towards more sustainable and efficient production methods, the roll former is poised to lead the way in shaping the future of metal forming technologies. As industries harness this innovative approach, the versatility and durability of Volcometal Parante will continue to open new avenues for growth and development in numerous applications.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025