roll former for parantes y rieles manufacturers

The Role of Roll Formers in Manufacturing Parentheses and Rails

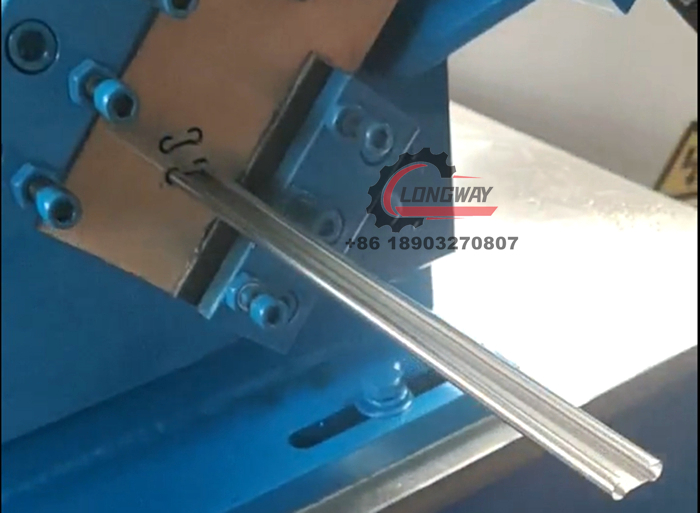

In the realm of manufacturing, precision and efficiency are paramount, particularly when it comes to the production of metal components such as parentheses and rails. Roll forming has emerged as a pivotal process in the manufacturing industry, allowing manufacturers to create complex shapes with remarkable consistency and minimal waste. Roll formers are specialized machines designed to shape metal sheets into desired profiles through a series of carefully designed roller dies.

The manufacturing of parentheses and rails often involves producing components that must meet stringent specifications regarding dimensions and tolerances. Here, roll forming excels due to its capability to produce long lengths of material with uniform cross-sections. This is particularly advantageous in industries such as construction and automotive, where structural integrity and performance are crucial.

One of the primary benefits of using roll formers to manufacture parentheses and rails is the reduction of material waste. Traditional machining processes often involve cutting away excess material, resulting in a significant amount of scrap. In contrast, roll forming utilizes the material efficiently, creating components from continuous sheets of metal. This not only minimizes waste but also lowers production costs, making it an environmentally friendly option.

roll former for parantes y rieles manufacturers

Moreover, roll forming allows for a high level of customization. Manufacturers can adjust roller dies to create various shapes and sizes of parentheses and rails to meet specific customer requirements. This flexibility is particularly beneficial in markets where diverse specifications are standard. For instance, in the construction sector, different types of rails may be required for various applications, including fencing, scaffolding, or structural support. Roll formers can accommodate these varied needs through quick changeovers and adaptable tooling.

In terms of production speed, roll forming stands out as a highly efficient process. Once the rollers are set up, the machine can produce components at a rapid pace, significantly reducing lead times. This efficiency is crucial in today’s fast-paced market, where customers demand swift delivery without compromising quality.

Additionally, modern roll formers are typically equipped with advanced technologies such as automation and computer numerical control (CNC). These innovations enhance the accuracy of the manufacturing process and contribute to the consistency of the finished products, ensuring that every piece meets the high standards expected by industry professionals.

In conclusion, roll formers for parentheses and rails represent a sophisticated solution for manufacturers seeking to optimize their production processes. By reducing material waste, allowing for customization, increasing production speed, and enhancing accuracy, roll forming stands as a vital technology in modern manufacturing. As industries continue to evolve and demand more efficient practices, the roll forming process will undoubtedly play an even more significant role in the future of manufacturing.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025