Roll Former Production Facility for Efficient Metal Forming Solutions

Roll Former Factory Innovative Solutions for the Metal Fabrication Industry

In the modern landscape of manufacturing, the roll forming process has emerged as a crucial technique for shaping metal materials into specific profiles needed for various applications. A roll former factory specializes in this innovative technology, which has become increasingly important in various industries such as construction, automotive, HVAC, and more. This article delves into the workings of a roll former factory, its significance, and the advantages it offers to manufacturers and customers alike.

Understanding the Roll Forming Process

Roll forming is a continuous bending operation in which a long strip of metal, usually in coil form, is fed through paired sets of rolls that gradually shape it into a desired profile. This process allows for high-speed production of parts that can be used in different assemblies, making it an efficient choice for manufacturers. The roll forming method is suited for producing parts with consistent cross-sections and high precision, which is essential for many applications.

The Role of a Roll Former Factory

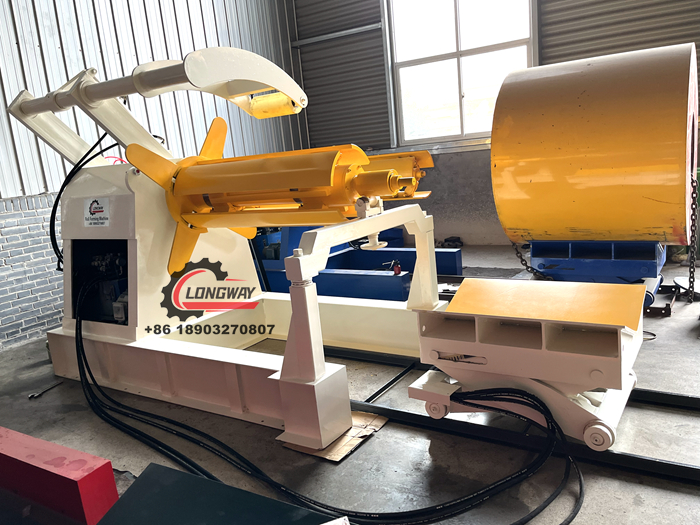

A roll former factory is equipped with advanced machinery and technology designed to carry out the roll forming process. These factories typically operate with several roll forming lines, each tailored to produce specific metal profiles according to the requirements of their clients. In addition to the roll forming machinery, these factories often include quality control stations, cutting equipment, and packaging areas to ensure a comprehensive production process that meets industry standards.

The factory begins by sourcing high-quality raw materials, primarily steel or aluminum coils, which are essential for producing durable products. The manufacturing process can vary based on the complexity of the designs, but it generally includes uncoiling, roll forming, cutting, and finishing processes to create finished products that meet the specifications provided by customers.

Customization and Versatility

roll former factory

One of the main advantages of a roll former factory is its capability to produce customized solutions. Manufacturers can request unique profiles that serve specific functions, enhancing their products' functionality and aesthetics. For example, architectural firms may seek specialized profiles for roofing or wall panels that not only conform to structural requirements but also align with aesthetic design considerations.

Additionally, the versatility of roll forming means that a roll former factory can cater to various industries. This adaptability is essential in today's fast-paced market, where customers require customized solutions quickly and efficiently. From simple shapes like brackets and channels to complex designs used in HVAC systems, the potential for innovation and customization in a roll former factory is virtually limitless.

Efficiency and Sustainability

Roll forming is known for its efficiency, especially when compared to other metal fabrication methods. The continuous nature of the process means that it can produce large quantities of parts with minimal waste. Moreover, the ability to work with thinner gauges of metal while still achieving high strength allows manufacturers to source materials more sustainably. Many roll former factories are now focusing on eco-friendly practices, striving to minimize their environmental footprint throughout the production process.

The reduction of scrap and waste not only benefits the environment but also contributes to cost savings for manufacturers. Efficient production techniques and optimized material usage can significantly lower operational costs, allowing businesses to remain competitive in an ever-evolving marketplace.

Conclusion

A roll former factory represents the pinnacle of modern metal fabrication technology, offering innovative solutions through the roll forming process. With its capacity for customization, efficiency, and sustainability, a roll former factory plays a vital role in supplying the necessary parts for a myriad of industries. As demand for metal products continues to rise, these factories will undoubtedly expand their capabilities to meet the growing needs of manufacturers worldwide, paving the way for even greater advancements in the field of metal fabrication. The future of manufacturing looks promising, with roll former factories leading the charge towards innovation and excellence in production processes.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025