roll former factories

Roll Former Factories An Overview of Equipment and Efficiency

In today's manufacturing landscape, efficiency and precision are paramount. One of the key players in achieving these objectives is the roll former, a specialized machine used to shape metal and other materials into specific profiles. Roll former factories are critical hubs where the intricacies of roll forming take place, catering to a variety of industries such as automotive, construction, and appliances. This article delves into the inner workings, benefits, and future of roll former factories.

The Process of Roll Forming

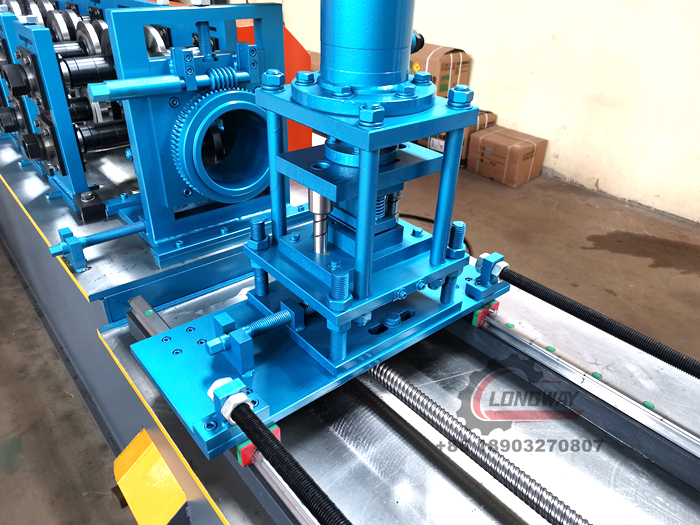

Roll forming is a continuous bending operation in which a long strip of metal is fed through a series of rollers, each altering the material's shape incrementally. The process begins with raw material, typically steel, aluminum, or other metals, which is fed into the roll former. This material passes through multiple sets of rollers, each designed to create a specific section of the desired profile. By adjusting the spacing and angle of the rollers, manufacturers can produce complex shapes that might otherwise be impossible to achieve with traditional manufacturing methods.

A key advantage of roll forming is its ability to create long lengths of uniform and precise shapes with minimal waste. The technique also supports high-speed production, making it suitable for large volumes of production. In addition, the inherent strength and durability of roll-formed products are vital factors that appeal to manufacturers and end-users alike.

Types of Roll Formers

Roll former factories typically utilize several types of roll formers, each tailored to specific applications. Some of the most common varieties include

1. Standard Roll Formers These machines are used for general-purpose roll forming and are suitable for a wide range of materials and thicknesses. 2. Precision Roll Formers Designed for applications that require exact tolerances, these machines utilize highly rigid structures and advanced controls to ensure precision.

3. Cut-to-Length Roll Formers These are integrated with cutting mechanisms that allow manufacturers to produce materials of precise lengths, reducing the need for further processing.

roll former factories

Infrastructure and Technology

The infrastructure of roll former factories is crucial for optimizing production efficiency and quality. Modern roll former factories invest heavily in advanced technologies, including automation, computer numerical control (CNC), and the Internet of Things (IoT). Automation streamlines the production process, reducing labor costs and minimizing human error. CNC technology enhances precision and allows for quick adjustments in production runs. IoT connectivity enables real-time monitoring and data analysis, improving decision-making and operational efficiency.

Furthermore, effective material handling systems within the factory help manage the flow of raw materials and finished products, reducing downtime and promoting a continuous manufacturing cycle.

Sustainability and Future Trends

As the demand for sustainable manufacturing practices grows, roll former factories are exploring eco-friendly methods. Many factories are integrating renewable energy sources, improving recycling practices, and seeking to minimize waste in the roll forming process. Additionally, advancements in materials technology are leading to the use of lighter and stronger metals, facilitating the production of more efficient products.

The future of roll former factories will likely be shaped by ongoing innovations in computer-aided design (CAD) and additive manufacturing. These technologies could enable even greater customization and efficiency, allowing manufacturers to respond swiftly to market demands.

Conclusion

Roll former factories play a pivotal role in modern manufacturing by providing precise, efficient, and versatile production methods. With advancements in technology and a focus on sustainability, these facilities are well-positioned to adapt to future challenges in the industry. As industries continue to evolve, roll former factories will remain indispensable for producing the high-quality materials essential to a wide range of applications, driving innovation and economic growth in the process. The continued investment in technology and sustainable practices promises to ensure that roll former factories can meet the demands of an ever-changing market landscape.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025