roller shutter slat roll forming machine

The Roller Shutter Slat Roll Forming Machine An Overview

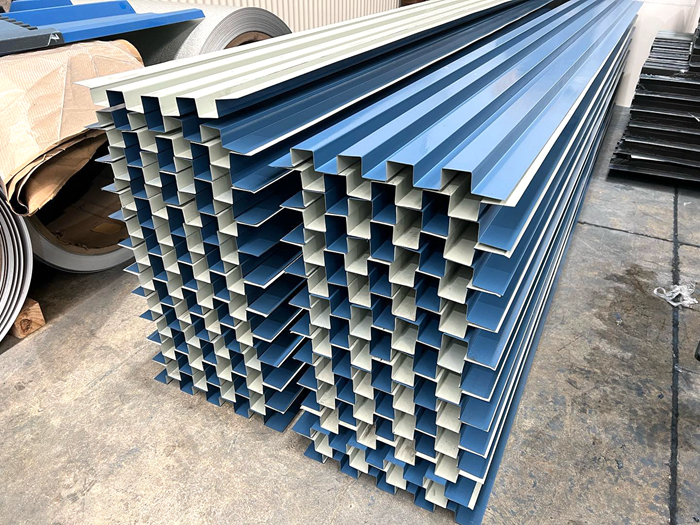

In the modern manufacturing landscape, efficiency and precision are critical. Among various production equipment, the roller shutter slat roll forming machine stands out as an essential tool for producing high-quality roller shutter slats. These machines are engineered to convert flat strips of metal into meticulously shaped slats used in roller shutters, which are increasingly popular in commercial and residential applications due to their sturdiness and security features.

The Working Principle

The roller shutter slat roll forming machine operates through a continuous process. Initially, a coil of metal, typically steel or aluminum, is fed into the machine. As the material moves through a series of specifically designed rollers, it is gradually transformed into the desired shape. The precise arrangement of rollers is crucial, as each stage applies gradual pressure to ensure the correct dimensions and tolerances are maintained.

The process begins with uncoiling the metal strip, which is then passed through a series of leveling rollers to eliminate any deformities. Following this, the metal passes through a series of shaping rollers that progressively form the slat profile. The machine may also incorporate additional features, such as cutting stations that enable it to produce slats of varying lengths, catering to specific customer demands.

Key Features and Benefits

One of the key advantages of using a roller shutter slat roll forming machine is its ability to produce slats at high speeds without compromising quality. This efficiency translates to higher production rates, which can significantly impact the profitability of manufacturing operations.

roller shutter slat roll forming machine

Moreover, these machines are designed for flexibility. They can be adjusted to create different slat profiles, allowing manufacturers to meet diverse market needs. This adaptability is particularly beneficial in today’s fast-paced environment, where consumer preferences can shift rapidly. With the right roll forming machine, manufacturers can swiftly switch production lines to accommodate new designs without requiring extensive downtime or additional investments in new machinery.

The use of automation in modern roll forming machines further enhances productivity. Many machines incorporate advanced digital controls that allow for precise programming of production parameters. This automation minimizes human error, ensuring that each slat produced meets rigorous quality standards.

Applications

Roller shutter slats manufactured using these machines are widely used across various sectors. In residential settings, they provide enhanced security and privacy for windows and doors. In commercial spaces, roller shutters are often used as storefronts, offering protection against theft and vandalism while allowing visibility of the merchandise on display.

Conclusion

The roller shutter slat roll forming machine is an invaluable asset in the manufacturing industry, offering efficiency, flexibility, and high-quality production. As security and convenience continue to drive demand for roller shutters, manufacturers equipped with advanced roll forming technology will be well-positioned to thrive in a competitive market. Investing in such machinery not only streamlines production processes but also opens the door to a broader range of product offerings, ensuring businesses can meet the evolving needs of their customers. As we look to the future, the role of roller shutter slat roll forming machines will undoubtedly become even more significant in industrial manufacturing.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025