roller shutter slat roll forming machine

The Roller Shutter Slat Roll Forming Machine An Essential Tool for Modern Fabrication

In the era of fast-paced industrialization, manufacturing technologies have evolved to meet the demands of efficiency and precision. The roller shutter slat roll forming machine stands out as an essential tool in the production of roller shutter systems, which are widely used for security and convenience in commercial and residential settings. This article explores the intricacies of roller shutter slat roll forming machines, their components, and their pivotal role in modern manufacturing.

Understanding the Roller Shutter System

Roller shutters are louvered doors or windows designed to roll up into a compact shape. They are commonly used in warehouses, storefronts, and homes for security and protection against external elements. The slats of these shutters are crucial; they must be durable yet lightweight. The manufacturing of these slats traditionally relied on manual processes, which were time-consuming and prone to errors. With the advent of automated machinery like the roll forming machine, production has become more efficient and standardized.

How Roller Shutter Slat Roll Forming Machines Work

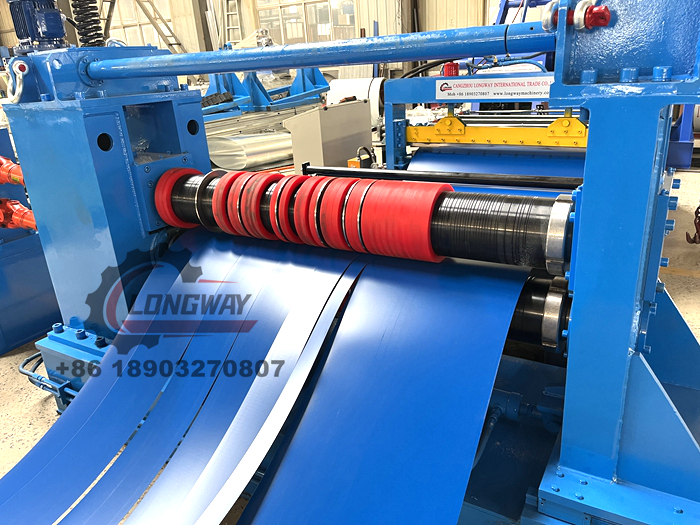

A roller shutter slat roll forming machine operates on a simple yet highly effective principle. The machine consists of a series of rollers that gradually shape a flat metal sheet into the desired profile of the slat. This process involves several key stages

1. Feeding The process begins with a continuous metal strip, typically made from steel or aluminum, being fed into the machine.

2. Roll Forming As the metal strip passes through a series of rollers, it is shaped progressively. Each roller applies pressure and molds the metal into the specific section that characterizes the slat.

4. Collection Finally, the completed slats are collected and prepared for subsequent assembly or installation.

roller shutter slat roll forming machine

This streamlined process not only enhances production speed but also ensures uniformity and accuracy in dimensions, which are critical for proper functioning and aesthetic appeal.

Benefits of Using Roll Forming Machines

The use of roller shutter slat roll forming machines offers numerous advantages

- Efficiency Automated processes can produce a high volume of slats in a fraction of the time it would take manually. This efficiency translates to lower labor costs and higher output.

- Consistency Automated machinery ensures that each slat is produced to the exact specifications, reducing the likelihood of defects compared to manual fabrication.

- Material Utilization Roll forming machines minimize waste by precisely using material for each slat, which is both cost-effective and environmentally friendly.

- Flexibility Modern machines can be easily adjusted to create different slat profiles or widths, allowing manufacturers to cater to various market needs without significant downtime.

- Lower Production Costs With increased efficiency and reduced labor needs, the overall cost of producing roller shutter slats decreases, making it an economically viable choice for manufacturers.

Conclusion

As the demand for roller shutters continues to grow in various industries, the roller shutter slat roll forming machine has solidified its position as a cornerstone of contemporary manufacturing. Its ability to produce high-quality, durable, and aesthetically pleasing slats with minimal waste highlights the evolution of industrial fabrication technologies. By adopting these machines, manufacturers can enhance their productivity, maintain competitive pricing, and meet the ever-growing demands of the market. In summary, the roller shutter slat roll forming machine is not just a piece of equipment; it is a key player in the manufacturing landscape, driving advancements and efficiency in the production of roller shutter systems.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025