roller shutter roll forming machine manufacturer

The Rise of Roller Shutter Roll Forming Machine Manufacturers

In recent years, the demand for roller shutters has surged, prompted by the growing need for security, insulation, and aesthetics in both commercial and residential buildings. Consequently, the manufacturing of roller shutter roll forming machines has become a crucial industry. These specialized machines are responsible for producing the various components of roller shutters, ensuring efficiency, durability, and innovation in design.

Roller shutters serve multiple purposes. They provide protection against burglary, reduce noise, and offer thermal insulation. As such, the quality and performance of roller shutters depend significantly on the precision and capability of the machines used to manufacture them. This has led to a heightened focus on the development of advanced roll forming technology, enabling manufacturers to meet the increasing market demands.

The Process of Roller Shutter Production

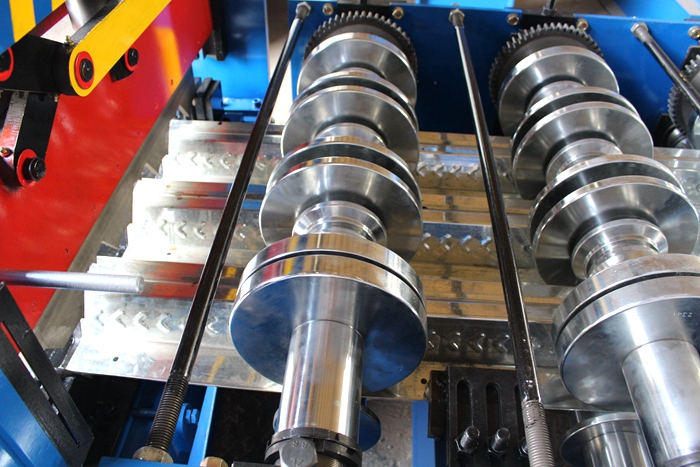

The production of roller shutters begins with the design phase, where manufacturers plan the specifications based on client requirements. Once the design is finalized, the roll forming machine takes center stage. This machine is responsible for forming metal strips into the desired profile, which involves feeding a metal coil into the machine where it is gradually shaped into slats, guides, and other necessary components.

Roller shutter roll forming machines utilize a series of rollers to bend and shape the metal profile accurately. The process is continuous, allowing for high-speed production with minimal waste. Additionally, these machines can be configured to create various profiles, catering to different design preferences and functional requirements.

Importance of Choosing the Right Manufacturer

roller shutter roll forming machine manufacturer

Selecting a reputable roller shutter roll forming machine manufacturer is essential for businesses looking to enter or expand in the roller shutter market. A reliable manufacturer should not only provide high-quality machinery but also offer comprehensive support, including installation, maintenance, and training for operators. This ensures that manufacturers can operate the machines effectively, optimizing production efficiency while minimizing downtime.

Moreover, innovative manufacturers invest in research and development, continuously improving their machines to incorporate the latest technology. Features such as automated adjustments, enhanced safety mechanisms, and energy-efficient operations are increasingly common in modern roll forming machines. Such advancements not only improve productivity but also contribute to cost savings in the long run.

Global Trends in Manufacturing

The roller shutter roll forming machine industry is witnessing several trends driven by technological advancements and market demands. Automation is at the forefront, with many manufacturers adopting CNC (Computer Numerical Control) technology to enhance precision and reduce human error. Automation also allows for more complex designs to be produced with ease, expanding the range of products available to consumers.

Sustainability is another critical aspect influencing manufacturing practices. With growing awareness of environmental issues, manufacturers are opting for eco-friendly materials and processes. This shift not only appeals to environmentally conscious consumers but also fosters compliance with regulatory standards related to sustainability.

Conclusion

The roller shutter roll forming machine manufacturing industry is thriving, bolstered by the rising demand for secure and aesthetically pleasing solutions in various settings. As businesses seek reliable partners in this field, the importance of choosing the right manufacturer becomes clear. By focusing on quality, innovation, and customer support, manufacturers can cement their position in this competitive market. As technology continues to evolve, the future of roller shutter production looks promising, with opportunities for growth and expansion both domestically and internationally. In a world where security and aesthetics are paramount, roller shutter roll forming machines will play a vital role in shaping the future of building infrastructure.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025