roller shutter door roll forming machine factory

The Evolution and Importance of Roller Shutter Door Roll Forming Machines

Roller shutter doors have become an essential component in modern security and convenience. These durable doors serve a myriad of applications, from commercial storefronts to residential garages, and their production requires sophisticated machinery known as roll forming machines. The manufacturing of roller shutter door systems is witnessing an unprecedented surge due to their versatility and reliability, making the role of roller shutter door roll forming machine factories critically important.

Understanding Roll Forming Machinery

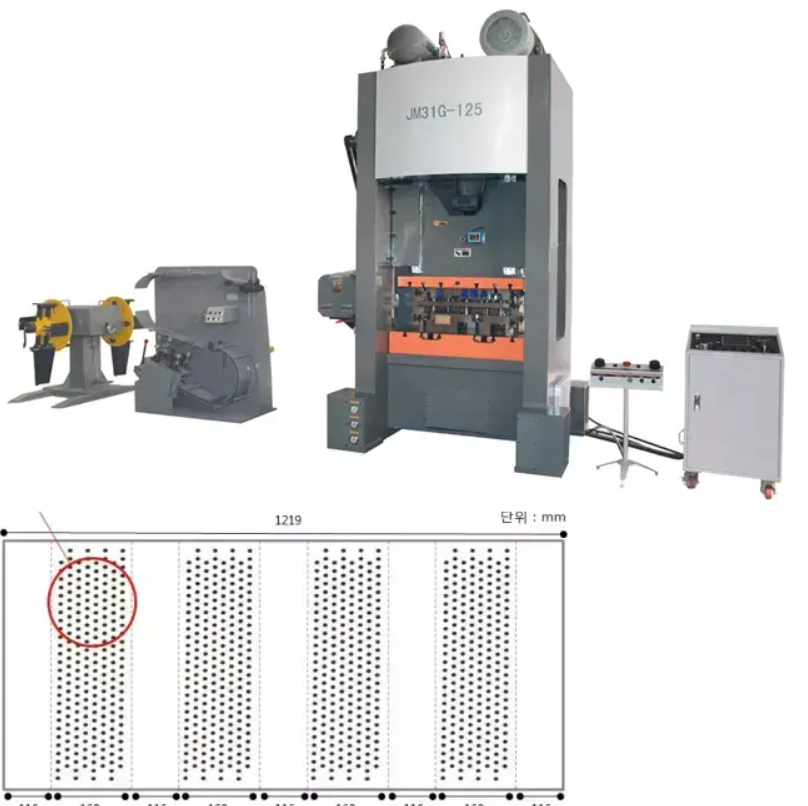

Roll forming is a continuous bending process in which a long strip of metal, typically steel or aluminum, is fed through successive pairs of rolls that gradually shape the material into the desired cross-section. The roll forming process is efficient and provides high-quality results, ideal for producing roller shutter components that require precision and durability. Companies invest heavily in these machines to meet growing demand with high efficiency and consistency.

Technological Advances in Manufacturing

Factory technology in producing roller shutter door roll forming machines has advanced significantly in recent years. Modern manufacturing facilities employ automation and computerized controls, allowing for quicker setup times and production runs. High-speed cutting, advanced tooling, and precision forming techniques have transformed the efficacy and output of roller shutter door production. Such advancements ensure that manufacturers can keep up with fast-paced market demands and provide superior products to their customers.

Customization Options

One of the hallmarks of roller shutter door production is the ability to customize. Roller shutter doors are not one-size-fits-all; they come in various sizes, colors, and materials tailored to specific applications. Roll forming machines are designed with customization in mind, allowing manufacturers to easily adjust settings for different product specifications. This flexibility opens avenues for producers to cater to niche markets, whether that means creating compact shutters for small spaces or heavy-duty options for high-security environments.

roller shutter door roll forming machine factory

Sustainability and Efficiency

As the world leans towards more sustainable practices, manufacturing facilities are increasingly adopting eco-friendly approaches. Roller shutter door roll forming machines today are optimized for energy efficiency and reduced waste. By implementing better material utilization practices and sourcing recyclable materials, manufacturers can minimize their environmental impact. This move not only promotes ecological responsibility but also resonates with consumers who prioritize sustainability in their purchasing decisions.

The Role of Skilled Workforces

While technology does much of the heavy lifting in modern factories, a skilled workforce remains at the core of the industry's success. Engineers, technicians, and operators who understand the nuances of roll forming processes are indispensable. They ensure that machines operate seamlessly, troubleshoot issues, and uphold quality control standards. Continuous training and development are critical to maintaining a knowledgeable team that can adapt to new technologies and methodologies.

Global Market Dynamics

The demand for roller shutter doors is not limited to a single geographic area; it is a global market driven by retail growth, construction projects, and an increased focus on security. Factories producing roll forming machines are strategically located around the world to minimize shipping costs and encourage quick delivery of products. Understanding market dynamics, including economic fluctuations and consumer preferences, is vital for these factories to thrive in a competitive landscape.

Conclusion

Roller shutter door roll forming machines represent a blend of technology, innovation, and reliability in the manufacturing sector. As factories continue to evolve with advancements in automation, sustainability, and customization, they play a pivotal role in meeting the growing demand for effective security solutions. The future looks promising for this industry, with ongoing innovations sure to enhance production capabilities and further elevate the standards of roller shutter door manufacturing. Investing in state-of-the-art roll forming technologies will enable manufacturers to stay ahead of the curve and satisfy the ever-changing needs of the market.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025