Roll Forming Machine - Precision Metal Forming Solutions

The Role of Roll Forming Machines in Modern Manufacturing

In the realm of modern manufacturing, efficiency and precision are paramount. One of the key players in achieving these goals is the roll forming machine. This innovative technology has revolutionized the way metal components are shaped and produced, becoming essential for various industries, including automotive, construction, and appliance manufacturing.

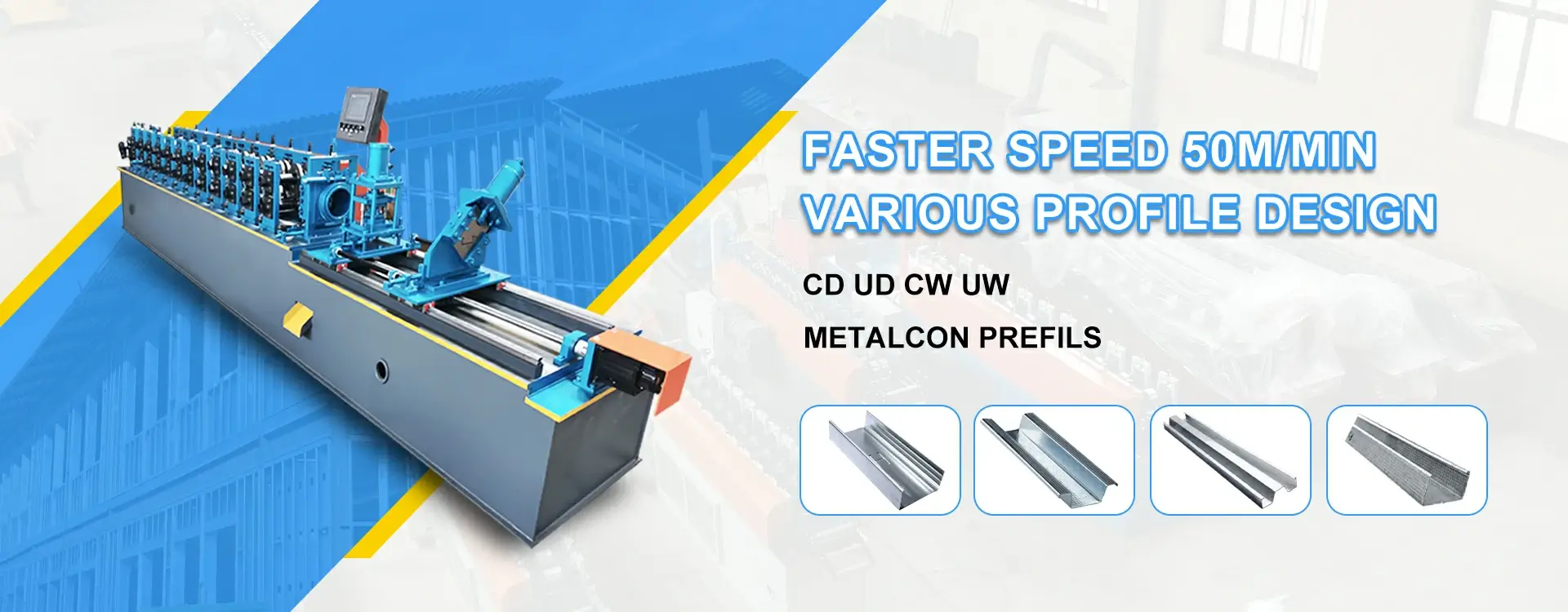

Roll forming is a continuous bending process that efficiently shapes long strips of metal into specific profiles. It involves passing a metal sheet through a series of rollers, each designed to incrementally shape the material to the desired configuration. The process is highly efficient, allowing for the production of complex shapes while maintaining uniformity and reducing waste. This makes roll forming machines a preferred choice for manufacturers looking to optimize their production lines.

One of the significant advantages of roll forming is its ability to produce consistent and repeatable results. Unlike other manufacturing methods that may involve cutting or punching, roll forming ensures that the final product retains its structural integrity and desired dimensions. This precision is critical in industries such as automotive manufacturing, where components must meet strict safety and performance standards.

roll forming machine

Moreover, roll forming machines are versatile and can be adapted to create various profiles, including channels, angles, and C-sections. This versatility enables manufacturers to cater to diverse needs while minimizing the number of different machines required. The ability to switch profiles quickly further enhances the efficiency of production lines, allowing for shorter lead times and faster response to market demands.

Additionally, roll forming machines can accommodate a range of materials, including aluminum, steel, and copper, making them suitable for numerous applications. The process can also be integrated with other manufacturing techniques, such as welding and stamping, to create more complex assemblies. This adaptability positions roll forming as a vital process in creating everything from building materials to automotive parts.

The economic benefits of roll forming are substantial. The continuous nature of the process, combined with high-speed production capabilities, significantly reduces labor costs and material waste. Additionally, the machines consume less energy compared to traditional fabrication methods, contributing to a more sustainable manufacturing approach.

In conclusion, roll forming machines play a crucial role in the landscape of modern manufacturing. Their ability to produce high-quality, consistent metal profiles while optimizing efficiency and reducing costs makes them indispensable in various sectors. As industries continue to evolve and demand innovative solutions, roll forming technology will undoubtedly remain at the forefront, shaping not only metal but also the future of manufacturing.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025