roll forming machine-Top 8 Roll Forming Machine Manufacturers

Top 8 Roll Forming Machine Manufacturers

For more than forty years DALLAN has been designing, producing, and installing compact, easy-to-use systems to manufacture top-quality products from steel coil, including punching machines, roll formers, laser cutting, and packaging machines.

Drawing on years of experience, DALLAN operates worldwide on all five continents across 75 countries. It is a benchmark in the manufacture of high-quality profiles for applications in the sectors of interior finishes, sun shading, air treatment, metal furniture, lighting, and many others.

Their specialization in pre-painted and pre-finished materials also means they study and create together with their customers’ tailor-made plants for manufacturing punched, folded sheet metal products; these plants are completed with assembly and packaging systems.

For more than seven decades ASC Machine Tools, Inc. has been working together with the Metal Building Industry and developed a reputation for innovation, high quality, and responsiveness in the design of Metal Wall and Roof Panel Lines.

They are proud to offer multiple custom-designed Panel Rollforming Lines for customers with low, medium, or high volume production needs. All of their Panel Lines are available as a SINGLE or DUAL HEIGHT Version with Pre-Cut and/or Post-Cut Shear Systems.

And the best, all of their panel lines are made in Spokane, WA USA!

Hydraulic Decoiler With Loading Car Automatic Uncoiler

The new ALPHA SERIES™ is a new revolutionary Panel Rollforming Line and the lower-cost option for customers with reduced production volumes. This line is designed with a perfect balance of Performance, Superior Quality, and Affordability and is the only Entry Level Rollforming line featuring Heavy Duty Cast Stands, Cast Bearing Blocks, and close-coupled Front-End.

The SELECT SERIES™ & CLASSIC SERIES™ are designed for customers with increased production needs and offer a variety of additional features to improve throughput and efficiency. Depending on the product, the Cut-off System, and Drive System these lines’ production speed can be between 150 and 400 FPM!

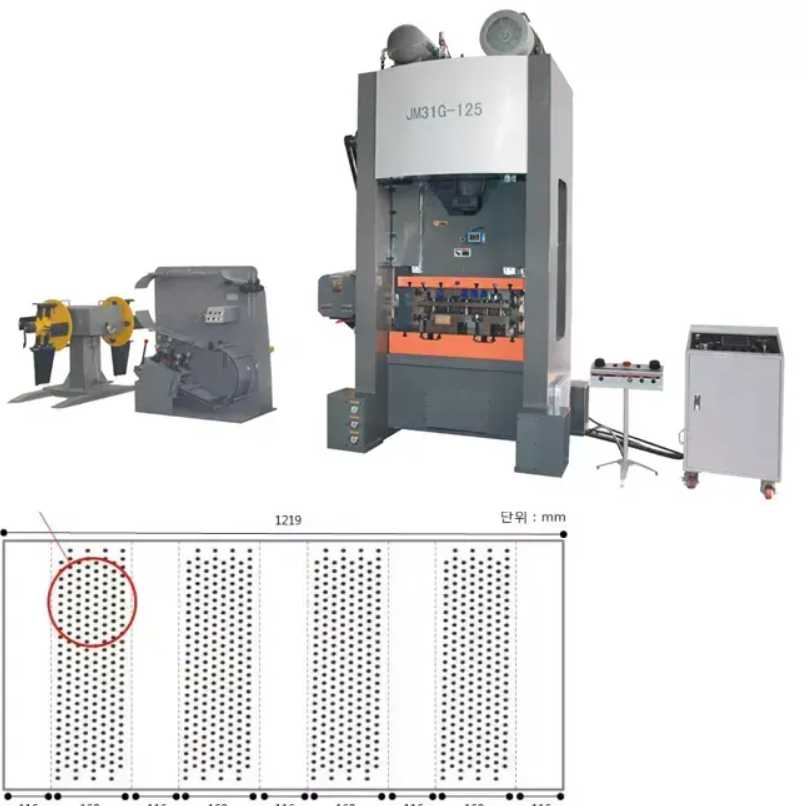

HARSLE is a modern enterprise that manufactures various kinds of NC and CNC press brake, shearing machines, hydraulic press, power press, Ironworker, laser cutting machine, and other related machines. They always adhere to the business principle of “ making better machines, providing first-class service “, so their products have been trusted widely in many industries.

Under the guidance of the “ professional, satisfactory, high performance-to-price ratio ” policy, they always try to provide a complete and thoughtful proposal to customers by their specialty and experience. What is more, they have a world-class R&D team to ensure that they can design professional and innovative machines. They can also provide overseas installation, training, maintenance, and commissioning services for each client to confirm that they can operate HARSLE machines properly and enjoy high performance and best service during operation.

They have a huge global customer source market, a good basic service network, and efficient service capabilities for modern sales. They devote themselves to different forms of customer service, strengthen customer care through relevant thematic services, continuously form a good reputation, and quickly improve brand reputation and customer satisfaction.

Custom roll forming machines, high-quality roll forming systems, and innovative roll forming technology: Ever since its foundation in 1949, DREISTERN GmbH & Co. KG has been setting new benchmarks in roll forming. They have established themselves as a global market leader by application of the very latest technologies in roll forming machines, their comprehensive know-how concerning roll forming units, and their ability to provide complete process execution.

Over 40 patents in the areas of forming technology, tool changing, and laser welding. More than 50 engineers in the Design & Development Department. More than 15 years of experience with computer simulations. An in-house test center with 10 test machines and high-performance CO2 lasers: impressive figures and facts document their pioneering spirit in the world of roll forming technology. With every roll forming the machine, you benefit from their inventions and technical evolutions because they develop your roll forming system so that it fulfills the standards of tomorrow.

Various services are part of their successful process cycle: you can order these services individually or combine them according to your requirements or use the complete process cycle for your roll forming system.

JUPITER was established in 2008 to assembling and manufacturing machines distinguished by quality, integrity, teamwork, and experience. Since their inception, they have witnessed steady and sustainable growth with the wide acceptance of products in the market.

They have maintained high quality and precision to deliver state-of-the-art machines in the market. They are backed by complete facilities to ensure on-time delivery of machines and prompt after-sales service.

They have experience of more than 10 years in manufacturing, supply & installation of roll forming machines, like metal roof sheet forming machine, crimping machine, C&Z section forming machines, Hat Profile, U channel, C channel, Deck profile, Solar panel, cable tray machine, Highway guard crash barrier, Stud channel machines, etc. They have all the necessary infrastructure & facilities available to complete the job on time.

They also provide customized solutions as per client specifications that truly help their company to build a strong association with them. They ensure that the cost of their services is less as compared to what their competitors have to offer. They have a huge client base which has been built mainly due to the quality-centric services that they offer to their clients.

GASPARINI S.p.A. designs and manufactures roll forming lines, sheet metal processing systems, integrated industrial processes. They offer technological solutions for the production of profiles and finished products in sectors such as logistics, construction, energy, and automotive.

Their roll forming systems using different technological solutions according to the customer’s production needs, solutions that are defined with the study and analysis of the request.

GASPARINI S.p.A. designs and produces roll forming systems, semi-automatic or automatic machines, and integrated systems for sheet metal processing.

It was founded in 1952, designing and manufacturing machinery and complete lines, and became a reference reality in the field of machine tools in the deformation sector, thanks to the ability to innovate and to constant technological updating. The roll forming lines represent the core business of the company which has been able to integrate other technologies to complete the production process.

The fields of application of the Gasparini S.p.A. lines are many and diversified, they are used in sectors such as automotive, construction, energy, and logistics.

Professionalism, reliability, know-how, and attention to customer requests represent the distinctive aspects of Gasparini.

Over the years, roll forming machines have developed from regional manufacturing to more localized. In their quest to meet the demand to bring craftsman and cutting-edge technology in the sheet metal industry, CIDAN Machinery designed one of the most high-quality, efficient, and cost-effective roll former series on the market – the rugged, robust, AMK Control equipped CIDAN QZ36!

CIDAN Machinery is proud to present a partner that has been leading the portable roll forming machines industry worldwide since 1991. New Tech Machinery (NTM) produces seamless gutter and metal roof panel machines that have revolutionized the metal construction industry by bringing versatile, easy-to-use roll forming products directly to the job site.

CIDAN Machinery – Americas was born in 2007 in a suburb nestled to the south of Atlanta, GA called Peachtree City. Now, that would make us a fairly young company. But their real story begins exactly 100 years prior in Göteneds Mekaniska Verkstad in Götene, Sweden. That’s pronounced “goot-en-eds”.

For a more in-depth look at their long-lasting legacy, read more about their history.

Shaoxing Inbon Machinery Co., Ltd. was founded by metal forming experts in all aspects including fields like tooling design, hydraulic & electrical design, software programming in 2008. They now consider themselves as the leading pioneer of the roll forming industry in China because of years of experience in providing high-end roll forming machines for both local and overseas markets, and all designing and manufacturing processes are in-house due to the intact and efficient technical forces. They are now supplying roll forming machinery at an excellent level of quality, tolerance, speed, and most importantly a complete range of machinery products like cold roll forming machine, metal roofing machine, purlin roll forming machine, stud and track roll forming machines for many industries such as pre-fabricated buildings, automobile, shelving and racking, infrastructure, and solar energy, etc…

Also benefiting from lower costs in China and years of experience of manufacturing, they believe they are now supplying the best & up-to-date machines built in China today and competitive prices compared to their counterparts throughout the world.

Their machines are made for clients’ specific needs, and they are also glad to provide you with years of insight, knowledge, and expertise in their fields. So please do not hesitate to ask us for an offer and let’s form their future with steel!

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025