Leading Roll Forming Line Machine Manufacturers | High-Quality Roll Forming Equipment

Understanding Roll Forming Line Machine Manufacturers

Roll forming is a continuous bending operation in which a long strip of metal, usually steel, is passed through a sequence of roller dies to form it into a desired cross-sectional profile. This efficient process is widely used in various industries including construction, automotive, and appliance manufacturing. The rise of roll forming line machines has led to a growing number of manufacturers specializing in this technology, each offering unique solutions to meet different market needs.

Manufacturers of roll forming line machines are tasked with creating precision equipment that meets exact standards of quality and performance. These machines must be able to handle various materials, including aluminum, copper, and different grades of steel. As industries demand more customized solutions, manufacturers have had to innovate and adapt their machinery to accommodate specific profiles, lengths, and thicknesses.

One of the key factors in choosing a roll forming line machine manufacturer is their experience and reputation in the industry. Established manufacturers often have a proven track record of delivering high-quality machines that are reliable and efficient. They typically offer comprehensive after-sales support, training, and maintenance services, which can be invaluable for companies looking to optimize their production processes.

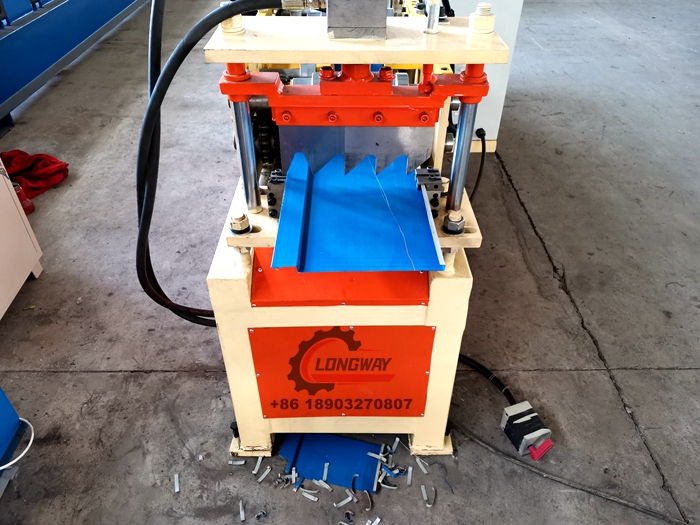

roll forming line machine manufacturers

Moreover, technological advancements have allowed manufacturers to integrate automation and digital technologies into their roll forming lines. Features such as computer numerical control (CNC) and real-time monitoring systems enhance precision and reduce labor costs, making the manufacturing process more efficient. Many forward-thinking manufacturers also invest in research and development to stay ahead of industry trends, focusing on energy-efficient designs that minimize waste and reduce operational costs.

Additionally, manufacturers often provide customization options to suit the specific needs of their clients. This could range from modifying the roll forming equipment to accommodate unique shapes or providing tailored solutions for specific production volumes. As the demand for bespoke products grows, the ability to offer such customization becomes a crucial competitive advantage.

In conclusion, the market for roll forming line machine manufacturers continues to expand, driven by the increasing demand for precision-engineered components across various industries. By focusing on quality, innovation, and customer service, manufacturers can not only meet current demands but also pave the way for future growth in the roll forming sector. Companies investing in these technologies can greatly benefit from enhanced production capabilities and improved product quality, contributing to overall operational success.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025