Ridge Cap Tile Production Line with Advanced Roll Forming Technology for Roofing Solutions

Ridge Cap Tile Roll Forming Machine An Overview

The construction industry is advancing rapidly with innovations in technology, especially in the manufacturing of roofing materials. One such crucial piece of equipment that has transformed this sector is the Ridge Cap Tile Roll Forming Machine. This specialized machine plays a significant role in producing ridge cap tiles, which are essential for ensuring the integrity and aesthetics of roof structures.

What is a Ridge Cap Tile?

Before diving into the machinery, it’s important to understand what ridge cap tiles are. These tiles are critical components used at the ridges of roofs where two slopes meet, providing both protection and a finished look. They help to prevent water infiltration, making roofs more weather-resistant. Ridge cap tiles are often made from various materials, including metal, clay, or concrete, but metal tiles have gained popularity due to their durability and lightweight properties.

The Functionality of Roll Forming Machines

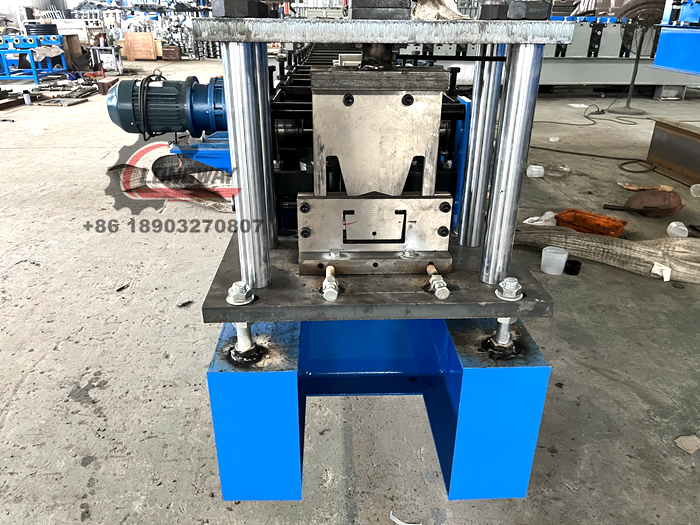

A Ridge Cap Tile Roll Forming Machine is designed to create these tiles through a continuous bending process. The machine takes flat metal sheets and gradually molds them into the specific shape of ridge cap tiles as they pass through a series of rollers. This method not only ensures uniformity in size and shape but also allows for mass production, making it a cost-effective solution for manufacturers.

The process begins with the feeding of metal sheets into the machine. The roll forming machine is equipped with multiple rollers, each strategically positioned to bend the metal incrementally. As the sheets move through these rollers, they take on the desired profile, creating ridge caps that are ready for installation.

ridge cap tile roll forming machine

Advantages of Using Ridge Cap Tile Roll Forming Machines

1. High Efficiency These machines are capable of producing a large volume of ridge cap tiles in a relatively short amount of time. This efficiency is crucial for meeting the growing demands in the construction sector.

2. Cost-Effectiveness By investing in a roll forming machine, manufacturers can significantly reduce labor costs and material wastage. The precision of the machine minimizes errors and optimizes the use of raw materials.

3. Customizable Designs Modern roll forming machines offer flexibility in design, allowing manufacturers to create ridge caps in various styles and profiles. This customization can cater to specific architectural requirements and regional preferences.

4. Durability and Quality The finished products are not only high in quality but also durable. Metal ridge caps produced by these machines are often resistant to cracking, fading, and corrosion, which enhances the lifespan of roofs.

Conclusion

In conclusion, the Ridge Cap Tile Roll Forming Machine is a vital asset in the roofing industry, combining technology and efficiency to meet market demands. Its ability to produce high-quality, customizable ridge cap tiles makes it an invaluable tool for manufacturers. As the construction industry continues to evolve, the adoption of such advanced machinery will undoubtedly play a crucial role in shaping the future of roofing solutions. Investing in a Ridge Cap Tile Roll Forming Machine is not just a step towards modernization; it is a commitment to delivering superior quality and efficiency in roofing materials.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025