ridge cap tile roll forming machine

The Ridge Cap Tile Roll Forming Machine An Essential Tool for Modern Roofing Solutions

As the construction and building management sectors continue to evolve, the demand for innovative and efficient solutions grows parallelly. One of the standout technologies in this realm is the ridge cap tile roll forming machine, an essential tool that has transformed how roofing materials are produced. This machine not only enhances productivity but also ensures that the roofing materials are made to precise specifications, which is crucial for the durability and aesthetic appeal of modern buildings.

Understanding Ridge Caps

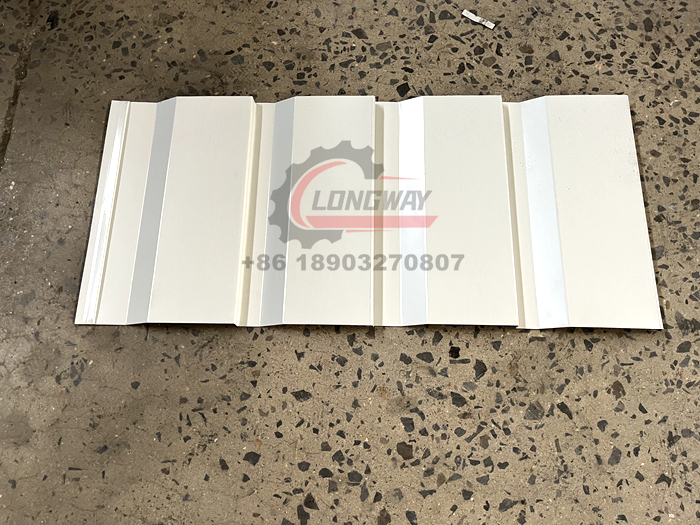

Ridge caps are critical components of roofing systems. They are designed to cover the ridge, which is the peak of a pitched roof, providing protection against water infiltration and ensuring a finished look to the roofline. Ridge caps can be made from various materials, including metal, ceramic, and concrete. However, metal ridge caps have gained popularity due to their durability, lightweight nature, and ease of installation. The ridge cap tile roll forming machine specializes in producing these metal caps efficiently and consistently.

Functionality of the Ridge Cap Tile Roll Forming Machine

The ridge cap tile roll forming machine operates through a series of processes that convert metal coils into finished ridge caps. The manufacturing process usually involves several key stages

1. Feeding Metal coils, typically made from galvanized steel or aluminum, are loaded into the machine. These coils are the raw materials from which the ridge caps will be formed.

2. Roll Forming The machine features a series of rollers that shape the metal as it is fed through. This process involves bending, cutting, and shaping the metal into the required profile for a ridge cap. The precision of this stage ensures each ridge cap produced meets exact specifications, crucial for proper installation and aesthetic appeal.

3. Cutting After the shaping process, the ridge caps are cut to the desired length. This step can be customized based on project requirements, allowing manufacturers to produce a variety of sizes in one production run.

ridge cap tile roll forming machine

4. Finishing To enhance longevity, many manufacturers apply protective coatings or finishes to the ridge caps. This not only improves the appearance but also increases resistance to rusting and environmental damage.

5. Quality Control Rigorous quality control measures are essential in ensuring that every ridge cap produced is of high quality. The machine is often equipped with sensors and measurement tools to ensure that all products meet industry standards.

Advantages of Using a Ridge Cap Tile Roll Forming Machine

1. Efficiency These machines can produce large quantities of ridge caps in a short amount of time, reducing production costs and enabling companies to respond rapidly to market demands.

2. Customization The ability to produce varied sizes and styles allows manufacturers to cater to specific client needs, enhancing customer satisfaction.

3. Quality and Consistency Automated processes result in high-quality ridge caps with consistent dimensions, reducing waste and the need for rework.

4. Versatility Ridge cap tile roll forming machines can be adapted to produce different profiles and materials, making them a versatile addition to any manufacturing facility.

Conclusion

In a world where speed, efficiency, and quality are paramount, the ridge cap tile roll forming machine represents a significant advancement in roofing material production. Its ability to produce high-quality, precise ridge caps quickly ensures that builders and contractors can meet the demands of modern construction projects with confidence. As technology continues to advance, the role of such machinery will become ever more critical in driving innovation and efficiency in the construction industry. Investing in a ridge cap tile roll forming machine not only enhances manufacturing capabilities but also contributes to the overall quality and longevity of roofing systems, making it an invaluable tool for any construction-related business.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025