Ridge Cap Roll Forming Machine Manufacturer for Efficient Construction Solutions

The Importance of Ridge Capping Roll Forming Machines in Modern Construction

In the ever-evolving world of construction and manufacturing, the efficiency of production processes has become a critical factor for success. One such innovation that has significantly improved the way roofing components are produced is the ridge capping roll forming machine. This specialized equipment is designed to create ridge caps efficiently, ensuring that roofs are not only functional but also aesthetically pleasing.

Understanding Ridge Capping

Ridge caps are essential components of roofing systems, serving as the peak cover of a roof where two sloping sides meet. They are crucial for providing protection against water seepage, wind, and other environmental factors. Proper ridge capping ensures that the roofing system maintains its integrity and durability over time. With the growing demand for high-quality roofing solutions, the necessity for advanced manufacturing techniques has led to the development of ridge capping roll forming machines.

The Functionality of Ridge Capping Roll Forming Machines

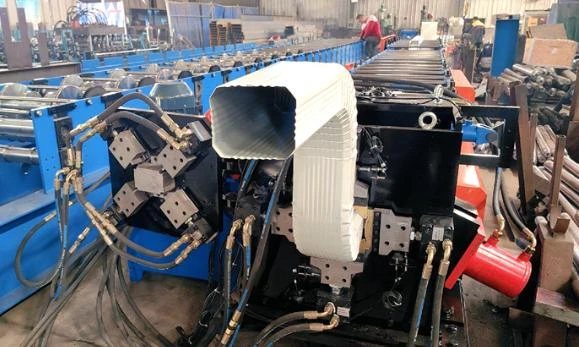

Ridge capping roll forming machines are sophisticated pieces of machinery that convert flat metal sheets into intricately shaped ridge caps. The process begins with feeding a coil of metal (often galvanized steel, aluminum, or other materials) into the machine. As the coil passes through a series of rollers, it is gradually shaped into the desired profile, which can be adjusted based on specific design requirements.

These machines can produce a range of ridge cap profiles, allowing manufacturers to meet diverse architectural styles and functional needs. The roll forming process is fast and efficient, allowing for high production rates while ensuring uniformity and precision in the final products. Furthermore, the automation involved in these machines reduces the need for manual labor, resulting in significant cost savings and improved safety on the production floor.

Advantages of Using Ridge Capping Roll Forming Machines

ridge capping roll forming machine factory

1. Efficiency and Speed One of the most significant advantages of ridge capping roll forming machines is their efficiency. These machines can produce large quantities of ridge caps in a short amount of time, making it easier for manufacturers to meet consumer demands promptly.

2. Customization and Flexibility Modern roll forming machines allow for easy adjustments to accommodate various designs. This flexibility enables manufacturers to cater to different building codes and aesthetic requirements, providing architects and builders with the freedom to explore unique roofing designs.

3. Material Conservation The roll forming process minimizes material waste significantly compared to traditional fabrication methods. By utilizing precise cuts and shapes, manufacturers can optimize their raw material usage, thus reducing costs and supporting sustainability efforts.

4. Durability and Strength Ridge capping produced through roll forming is inherently robust, ensuring longevity and reliability. The processes used in creating these components often enhance the material’s ability to withstand extreme weather conditions, further extending the lifespan of roofing systems.

5. Aesthetic Appeal A well-formed ridge cap adds character to any roof. With the capability to create various styles and finishes, these machines play a critical role in meeting the aesthetic needs of modern architecture.

The Future of Ridge Capping Production

As the construction industry continues to advance, the demand for high-quality, efficiently-produced roofing components will only grow. The evolution of ridge capping roll forming machines shows promise, with ongoing technological innovations aiming to further enhance their efficiency and capabilities. Automation, improved material handling systems, and integrated computer controls are just a few of the developments that will likely shape the future of these machines.

In conclusion, ridge capping roll forming machines have revolutionized the production of roof ridge caps, making them essential in modern construction. Their efficiency, flexibility, and ability to produce high-quality products make them indispensable for manufacturers. As the industry continues to evolve, these machines will remain at the forefront, leading the way towards more efficient and aesthetically pleasing roofing solutions. The investment in such technology not only bolsters production capabilities but also enhances the overall quality of roofing systems that ultimately protect our homes and businesses.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025