Ridge Cap Roll Forming Machines from Leading Factories for Efficient Metal Roofing Solutions

The Importance of Ridge Cap Roll Forming Machines in Construction

Ridge cap roll forming machines play a crucial role in modern construction, particularly in the roofing industry. These specialized machines are designed to manufacture ridge caps, which are essential components used to cover and protect the joints of sloped roofs. The effectiveness and efficiency of ridge cap roll forming machines have made them indispensable in factories specializing in the production of roofing materials.

Understanding Ridge Caps

Ridge caps serve multiple purposes in roofing. They not only provide a finished look to the roof but also protect the seams from water penetration, wind, and debris. Properly installed ridge caps help enhance the durability of a roof, ensuring that it can withstand various weather conditions. As such, the demand for high-quality ridge caps has significantly increased, leading to the growing popularity of ridge cap roll forming machines in factories.

The Functionality of Ridge Cap Roll Forming Machines

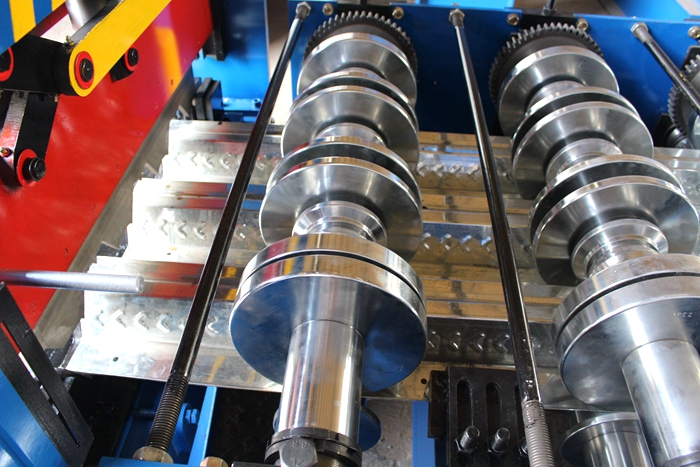

A ridge cap roll forming machine is designed to convert coiled metal sheets into ridge caps through a continuous process that involves feeding the metal through a series of rollers. These rollers gradually shape the metal into the desired profile. The process is highly efficient, allowing for the mass production of ridge caps with consistent quality and precision.

The machines can handle various materials, including steel, aluminum, and stainless steel. They are equipped with advanced technology that allows for quick adjustments in thickness and profile, catering to the unique requirements of different roofing projects. This flexibility is vital for manufacturers aiming to meet specific customer demands while maintaining high productivity levels.

Benefits of Using Ridge Cap Roll Forming Machines

1. Efficiency and Speed One of the primary advantages of ridge cap roll forming machines is their ability to produce large quantities of ridge caps quickly. This efficiency significantly reduces labor costs and production time, allowing factories to meet high demand without compromising quality.

ridge cap roll forming machine factories

2. Customization With the ability to adjust settings and profiles, manufacturers can easily customize ridge caps to fit various architectural designs. This adaptability is increasingly important as homeowners and builders seek unique roofing solutions that enhance aesthetic appeal and functionality.

3. Cost-Effectiveness By utilizing roll forming techniques, factories can minimize waste and reduce material costs. The precision of the machinery ensures that each cut and profile is accurate, leading to less scrap material.

4. Durability and Quality Ridge cap roll forming machines produce components that meet industry standards for durability and quality. The continuous nature of the roll forming process results in uniform products that are less likely to have defects.

5. Reduced Labor Intensity The automation of the production process means fewer workers are needed to operate the machinery compared to traditional methods. This shift not only lowers labor costs but also minimizes the chances of human error.

Market Trends and Future Outlook

As the construction industry continues to evolve, the demand for ridge cap roll forming machines is expected to rise. With advancements in technology, manufacturers are continuously improving the efficiency and capabilities of these machines. Innovations such as smart technology integration and enhanced automation are making roll forming processes even more streamlined and effective.

Moreover, the growing emphasis on sustainable building practices is driving the demand for high-quality, recyclable materials in roofing applications. Ridge cap roll forming machines can cater to this trend by enabling the production of eco-friendly roofing solutions that meet environmental standards.

In conclusion, ridge cap roll forming machines are a vital component of modern manufacturing, driving both efficiency and quality in the production of essential roofing materials. As technology advances and market demands evolve, these machines will continue to play a pivotal role in the construction industry, ensuring that roofs are not only durable but also aesthetically pleasing and environmentally sustainable.