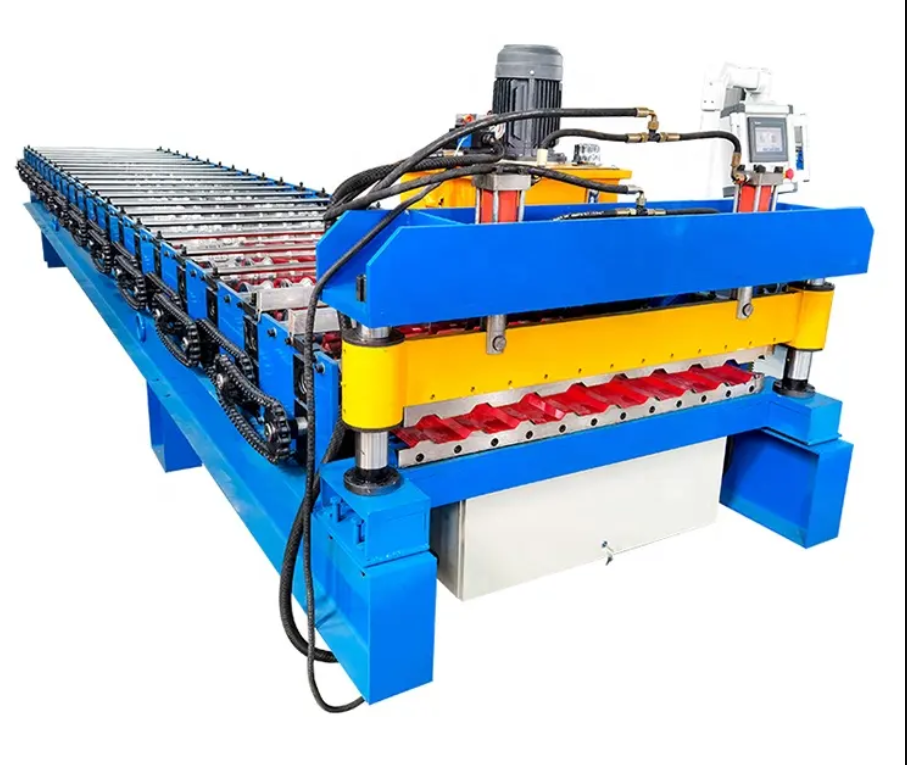

rib roof machine

Understanding Rib Roof Machines A Comprehensive Overview

In the ever-evolving construction industry, the efficiency and effectiveness of roofing systems are paramount. One significant advancement in this realm is the rib roof machine, an innovative tool designed to streamline the process of creating ribbed metal roofs. This article delves into the functionality, benefits, and applications of rib roof machines, illustrating why they are a cornerstone of modern roofing solutions.

What is a Rib Roof Machine?

A rib roof machine is a specialized piece of equipment used to produce ribbed metal panels. These panels are characterized by their ridged surface, which not only enhances their aesthetic appeal but also improves their structural integrity. The machine typically features a series of rollers and press tools that mold flat metal sheets into desired ribbed shapes. The precision of these machines allows for consistent product quality and optimal use of materials.

Key Functions and Features

Rib roof machines come equipped with various features that enhance their usability and efficiency. Some of these features include

1. Roll Forming Technology At the core of rib roof machines is the roll forming process, where flat metal coils are continuously fed through a series of rollers to achieve the desired profile. This ensures high production rates and uniform panel quality.

2. Customization Options Many rib roof machines offer adjustable settings, allowing users to customize the rib depth, width, and spacing according to specific project requirements. This adaptability makes them suitable for various roofing applications, from residential to industrial buildings.

3. Durability and Maintenance These machines are built to withstand rigorous usage, often made from high-strength materials. They are also designed for easy maintenance, ensuring that they can operate efficiently over long periods without frequent downtime.

Advantages of Using Rib Roof Machines

rib roof machine

The use of rib roof machines brings several advantages to the construction process, including

1. Cost-Effectiveness By enabling quick production of quality panels, rib roof machines significantly reduce labor costs and material waste. The ability to produce customized sizes on-site also eliminates the need for costly shipping of pre-made components.

2. Enhanced Structural Performance Ribbed panels provide superior strength and rigidity compared to flat metal sheets. The ribbing increases the load-bearing capacity of the roofs, making them ideal for areas susceptible to heavy snowfall or high winds.

3. Aesthetic Versatility Ribbed roofing panels come in various designs, colors, and finishes, allowing architects and builders to achieve desired aesthetics without compromising on functionality.

4. Sustainability Many rib roof machines are capable of processing recyclable materials, contributing to more sustainable construction practices. Additionally, metal roofs are known for their energy efficiency, often reflecting heat and reducing cooling costs.

Applications in the Construction Industry

Rib roof machines find applications across various sectors, including

- Residential Buildings They are commonly used to produce roofs for homes, providing a durable and visually appealing finish. - Commercial Structures Businesses often opt for ribbed metal roofs for their longevity and minimal maintenance requirements. - Industrial Facilities Warehouses and factories benefit from the robustness of ribbed roofs to withstand harsh weather conditions and heavy loads.

Conclusion

In summary, rib roof machines have revolutionized the roofing industry by providing efficient, durable, and aesthetically pleasing solutions for various construction needs. Their ability to generate high-quality ribbed metal panels at a reduced cost makes them invaluable to builders and contractors. As the construction sector continues to evolve, the role of rib roof machines will likely grow, further solidifying their place as essential tools in modern roofing systems.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025