rack roll forming machine manufacturer

The Importance of Choosing the Right Rack Roll Forming Machine Manufacturer

In today’s manufacturing landscape, the need for efficiency and precision is paramount. Among the various components that constitute a successful production line, one crucial element is the rack roll forming machine. This innovative piece of equipment allows businesses to produce metal racks and frames with remarkable speed and accuracy. However, the effectiveness of this machinery largely depends on the manufacturer from whom it is sourced. Therefore, selecting the right rack roll forming machine manufacturer is vital for any industry that relies on such technology.

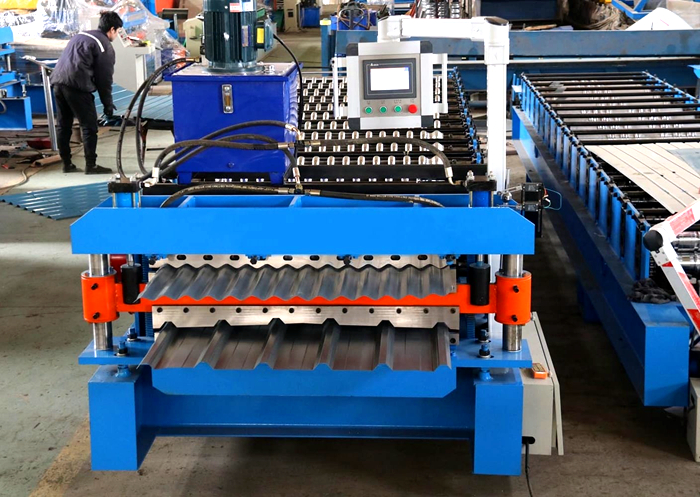

Understanding Rack Roll Forming Machines

Rack roll forming machines are designed to convert flat metal sheets into specific shapes required for producing racks and various structural components. These machines use a series of rollers to gradually shape the metal, ensuring a consistent and precise finish. Industries such as automotive, construction, and storage heavily depend on these machines for creating durable and reliable products. Given the complexity and investment involved in acquiring this machinery, businesses must make informed decisions when choosing a manufacturer.

What to Look for in a Manufacturer

1. Experience and Reputation One of the first criteria to consider is the manufacturer's experience in the industry. A company with a long track record is likely to have perfected their processes and technology over the years. Additionally, researching their reputation through customer reviews and case studies can provide insights into their reliability and quality of service.

rack roll forming machine manufacturer

2. Customization Options Every business has unique requirements. An ideal rack roll forming machine manufacturer should offer customization options to tailor machines according to specific production needs. Whether it’s the size, shape, or thickness of the materials being processed, having a manufacturer that understands and accommodates these needs can lead to significant operational advantages.

3. Quality of Materials and Engineering The durability and efficiency of the machines largely depend on the quality of the materials used and the engineering behind the design. A reputable manufacturer should use high-grade materials and advanced engineering practices to ensure the machines have a long operational life and require minimal maintenance.

4. Support and Service Post-purchase support is a crucial factor that should not be overlooked. Machinery can face operational challenges; thus, having access to a responsive customer service team and technical support can make a significant difference. Check if the manufacturer offers training for your staff, maintenance services, and readily available spare parts.

5. Innovative Technology The manufacturing sector is continuously evolving, with new technologies leading to better efficiency and output. Choose a manufacturer that embraces innovation and incorporates cutting-edge technology into their machines. This ensures you are investing in equipment that will remain competitive in the coming years.

Conclusion

Investing in a rack roll forming machine is a significant decision for any business aiming to enhance its manufacturing capabilities. By carefully evaluating potential manufacturers based on their experience, customization options, quality, support, and innovative practices, businesses can find the right partner to meet their production needs. In an industry where precision and efficiency are vital, the right rack roll forming machine manufacturer can not only improve productivity but also contribute to overall business success. Therefore, take the time to research and choose wisely; the right investment today can yield significant benefits tomorrow.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025