quick changeable c/z purlin roll forming machine

Quick Changeable C/Z Purlin Roll Forming Machine Revolutionizing Steel Fabrication

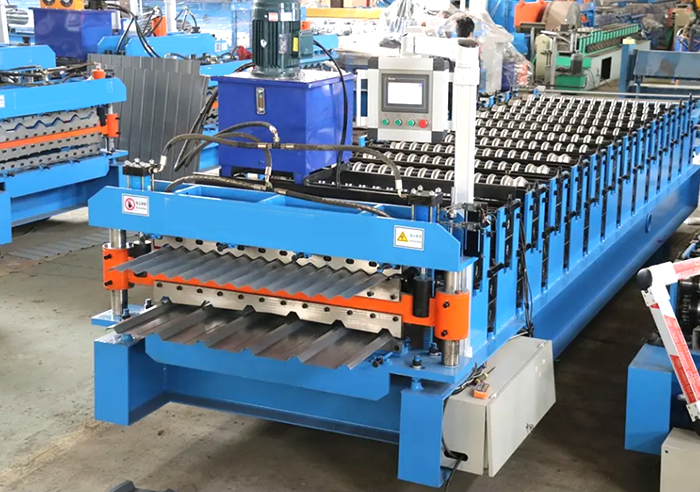

The construction industry has always been at the forefront of innovation, with advancements in technology leading to improved efficiency and reduced costs. Among the most significant developments in this field is the introduction of the quick changeable C/Z purlin roll forming machine. This sophisticated piece of machinery is designed to streamline the production of purlins, essential components used in nearly every type of structure, and it is changing the landscape of steel fabrication.

Understanding C/Z Purlins

Before delving into the machine itself, it's crucial to understand the materials it processes. C and Z purlins are horizontal structural elements used to support roof and wall panels in buildings. Their adaptability makes them suitable for various applications, from industrial warehouses to residential complexes. The main difference between the two is their shape C purlins have a channel-like form, while Z purlins have interlocking capabilities that provide added strength.

Traditionally, the production of these purlins involved a lengthy setup process, often requiring multiple machines and manual adjustments. This approach not only consumed time but also resulted in increased labor costs and waste material. Herein lies the innovation of the quick changeable C/Z purlin roll forming machine.

Key Features of the Quick Changeable Machine

1. Versatility One of the standout features of this machine is its ability to produce both C and Z purlins without requiring extensive retooling. With the right setup, operators can switch between specifications in a matter of minutes, significantly reducing downtime.

2. Efficiency By integrating advanced technology, these machines can produce high volumes of purlins with minimal manual intervention. Automated controls allow for precise adjustments, ensuring consistent quality across batches while maximizing production speed.

3. Reduced Material Waste The enhanced accuracy of the roll forming process minimizes scrap material, contributing to a more sustainable production method. This not only benefits the environment but also lowers overall production costs.

quick changeable c/z purlin roll forming machine

4. User-Friendly Interface Modern quick changeable roll forming machines come equipped with intuitive control systems, making them easier for operators to use. Training times are reduced, and employees can quickly adapt to new models, further enhancing overall productivity.

5. Compact Design Space considerations are paramount in many manufacturing facilities. This machine's compact design allows it to fit into smaller production areas, maximizing floor space while still delivering high output levels.

The Impact on the Construction Industry

The introduction of quick changeable C/Z purlin roll forming machines has ushered in a new era in steel fabrication. With the ability to rapidly produce two commonly used profiles, contractors can more efficiently meet project deadlines. This capability is especially advantageous in large-scale projects where time is of the essence.

Furthermore, the reduction in labor and material costs translates into significant savings for construction companies. The quick changeable feature means fewer machines are required to produce different styles of purlins, leading to reduced initial investments and ongoing maintenance expenses.

Finally, as the demand for sustainable building practices continues to grow, the environmental benefits of reduced waste and lower energy consumption position these machines as an attractive option for eco-conscious builders.

Conclusion

The quick changeable C/Z purlin roll forming machine is a testament to how technology can enhance productivity and efficiency in steel fabrication. By simplifying the production process and offering versatility, it allows manufacturers to respond to the dynamic needs of the construction industry more effectively than ever before. As the landscape of building materials and construction techniques evolves, innovations like this machine will play a critical role in shaping a more efficient and sustainable future. For anyone involved in the construction or manufacturing sectors, investing in such technology is not just a step towards modernization—it's a leap into the future of construction.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025