purlin zee roll forming machine

Purlin Zee Roll Forming Machine Revolutionizing Steel Construction

In the world of construction, efficiency and precision are paramount. One key player in the realm of metal processing equipment is the Purlin Zee Roll Forming Machine. This specialized machine has gained significant attention for its ability to produce high-quality metal purlins with remarkable speed and accuracy. Understanding the capabilities and advantages of this equipment is essential for anyone involved in the construction and manufacturing sectors.

What Is a Purlin?

Before diving into the intricacies of the roll forming machine, it’s important to understand what a purlin is. Purlins are horizontal structural members used in construction to support roofs and sometimes walls. They are typically made from steel and come in various shapes, with the 'Z' shape being one of the most common due to its structural advantages. Z purlins are designed to provide outstanding strength-to-weight ratios, making them ideal for diverse roofing and walling systems.

How Does the Purlin Zee Roll Forming Machine Work?

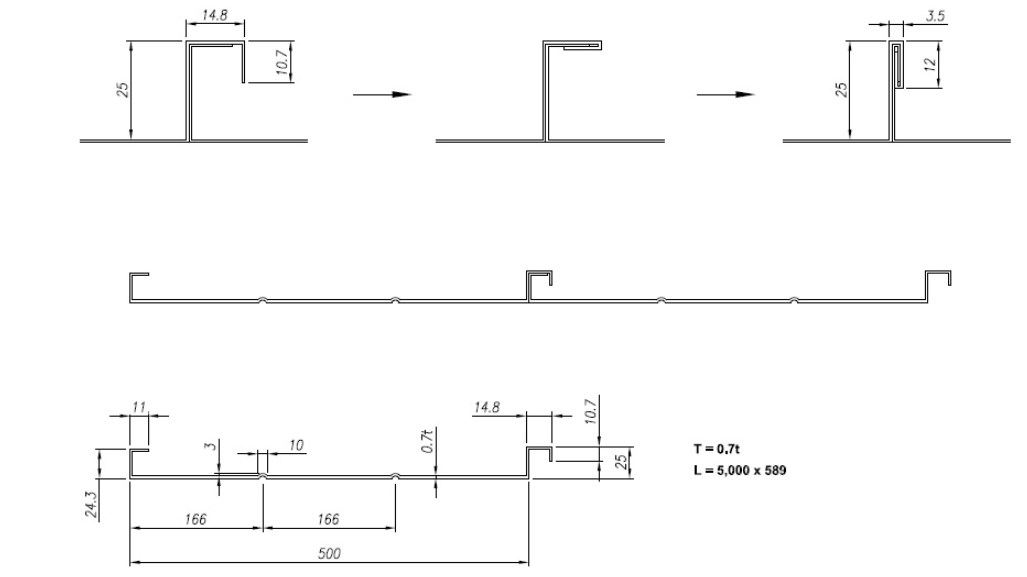

A Purlin Zee Roll Forming Machine utilizes a series of rollers to continuously shape raw steel sheets into the desired profile. The process begins with feeding flat steel into the machine, where it passes through a set of progressively arranged rollers that gradually bend the metal into the ‘Z’ shape. This method not only enhances the efficiency of production but also ensures uniformity and precision in the finished product.

The machine can typically produce purlins in various thicknesses and lengths, making it a highly versatile tool for manufacturers. Advanced models may also feature programmable controls that allow for easy adjustments, enabling users to switch between different purlin sizes without extensive downtime.

Benefits of Using a Purlin Zee Roll Forming Machine

purlin zee roll forming machine

1. Efficiency One of the most significant advantages of using a roll forming machine is the speed at which it operates. The continuous nature of the process means that large volumes of purlins can be produced in a fraction of the time compared to traditional methods.

2. Cost-Effectiveness By reducing the time and labor required to produce purlins, manufacturers can lower their production costs. Moreover, the reduced wastage of raw materials contributes to overall savings, making it a financially savvy choice for businesses in the construction sector.

3. Durability and Strength The roll forming process enhances the strength of the metal, allowing for the production of robust purlins that can withstand various environmental stresses. This durability translates into longer-lasting structures, which is a critical consideration in construction.

4. Customization Different construction projects have unique requirements. Purlin Zee Roll Forming Machines can be adjusted to create purlins of varying heights, thicknesses, and lengths, providing manufacturers with the customization necessary to meet specific project needs.

5. Reduced Waste The precision manufacturing process minimizes scrap material, resulting in a more sustainable operation. This efficiency is particularly beneficial for companies looking to improve their environmental impact.

Conclusion

The Purlin Zee Roll Forming Machine represents a significant advancement in the construction industry, enabling manufacturers to produce high-quality, durable purlins quickly and economically. As the demand for efficient building materials continues to rise, investing in advanced machinery like the Purlin Zee Roll Forming Machine not only enhances productivity but also ensures that companies remain competitive in an ever-evolving market. Embracing such technologies will undoubtedly pave the way for more sustainable and resilient construction practices in the future.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025