High-Quality Purlin Roll Forming Machine Suppliers for Efficient Production

Purlin Roll Forming Machine Manufacturer A Vital Player in the Construction Industry

In the ever-evolving construction landscape, efficiency and quality are paramount. One of the essential components in modern construction is the use of purlins—horizontal structural members in a roof or wall that support the load of the roof decking and its associated load. As the demand for strong, lightweight, and durable building materials grows, so does the reliance on advanced manufacturing processes. This is where the purlin roll forming machine manufacturer plays a critical role.

Understanding Purlin Roll Forming Machines

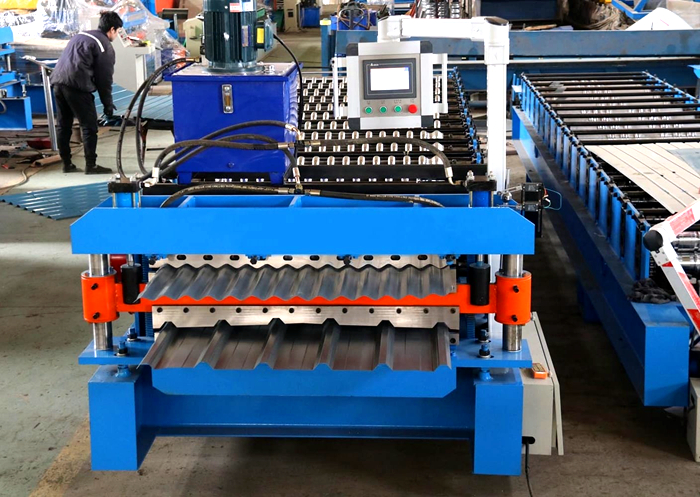

Purlin roll forming machines are specialized equipment designed to create purlins from metal sheets. The process involves feeding metal strips through a series of rollers that progressively shape the material into the desired profile. These machines can produce various types of purlins—C, Z, and U shapes—each catering to different structural requirements. The precision and speed at which these machines operate are crucial for meeting the high demands of construction projects.

Advantages of Using a Purlin Roll Forming Machine

1. Customization One of the significant advantages of purlin roll forming machines is their ability to create customized profiles that meet specific project needs. Manufacturers can adjust the machine settings to produce various sizes, thicknesses, and shapes of purlins, ensuring that every construction project is catered to effectively.

2. Efficiency Roll forming is a highly efficient process. Once set up, the machine can run continuously, producing large quantities of purlins in a short time. This high output is essential for construction companies that need to adhere to tight deadlines while maintaining quality standards.

3. Material Savings The roll forming process is designed to minimize waste. By utilizing metal sheets efficiently, manufacturers can produce purlins with less scrap material compared to traditional cutting methods. This aspect not only helps the environment but also lowers costs for construction firms.

4. Durability and Strength Purlins produced by roll forming machines exhibit excellent tensile strength, which is vital for structural integrity. The continuous profile created during the forming process ensures that the material maintains consistent strength throughout, making it ideal for supporting roofs and wall systems.

5. Ease of Installation Lightweight purlins are easier to handle and install, speeding up the construction process. This advantage not only saves time but can also lead to lower labor costs, benefiting overall project budgets.

purlin roll forming machine manufacturer

Choosing the Right Manufacturer

Selecting the right purlin roll forming machine manufacturer is critical to ensuring ongoing reliability and performance in construction projects. Here are a few factors to consider when making a choice

1. Experience and Reputation Look for manufacturers with a solid track record in the industry. A reputable company with years of experience is likely to provide better quality machines and support.

2. Machine Quality The quality of the machine itself is crucial. Inspect the materials, engineering, and technology used in the manufacturing process. Machines that are built to last will save on maintenance costs and production downtime.

3. Customer Support and Service A distinguished manufacturer should offer excellent customer service and support, including installation assistance, technical support, and maintenance services. This partnership ensures that any potential issues are promptly addressed.

4. Customization Options Different projects may require unique specifications. Choose a manufacturer that offers customizable machines tailored to specific needs.

5. Cost-Effectiveness While price should not be the sole determinant, it is essential to consider the total cost of ownership. Assess the initial investment against potential savings in material, labor, and maintenance.

Conclusion

In conclusion, the role of a purlin roll forming machine manufacturer is pivotal in the construction industry. By providing efficient, customizable, and high-quality machinery, these manufacturers enable builders to meet the demands of modern construction. With the increasing focus on sustainability, performance, and cost-effectiveness, investing in advanced roll forming technology is a smart choice for the future of building construction. As the industry continues to grow and evolve, the importance of these manufacturers will only increase, facilitating the development of structures that are not only durable but also innovative.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025