purlin roll forming machine manufacturer

The Evolution and Benefits of Purlin Roll Forming Machines

In the realm of modern construction and manufacturing, the importance of efficient and precise production processes cannot be overstated. Among the numerous innovations that have emerged to streamline construction practices, purlin roll forming machines have gained significant attention. These machines are pivotal in manufacturing purlins, which are essential structural components in building frameworks.

Understanding Purlins

Purlins serve as horizontal supports for roofs or walls, playing a critical role in the structural integrity of buildings. They provide stability and distribute the weight of the roofing material. These components can be made from various materials, including steel, allowing builders to choose options based on strength, weight, and cost. The evolution of purlin design and manufacturing techniques has led to an increased demand for sophisticated machinery capable of producing purlins with precision and speed.

The Functionality of Purlin Roll Forming Machines

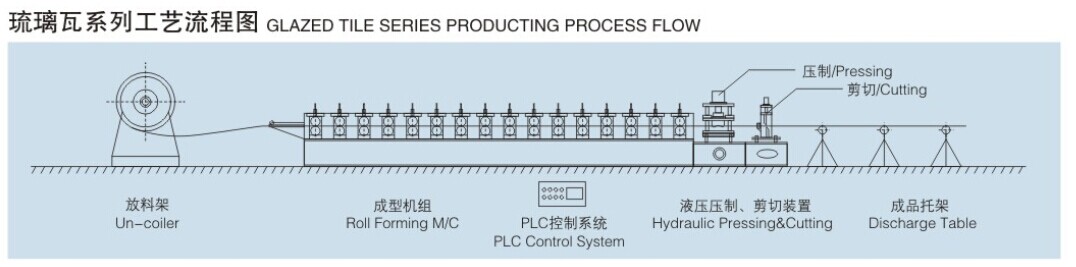

A purlin roll forming machine is specifically designed to transform metal coils into purlins. The process begins with feeding a coil of metal into the machine, where it is gradually shaped into the desired profile through a series of rollers. This method of continuous production allows for the creation of longer and more uniform purlins compared to traditional manufacturing techniques.

These machines can produce various purlin profiles, including C, Z, and U shapes, catering to different structural requirements. The ability to adjust the specifications easily makes purlin roll forming machines highly versatile tools in modern manufacturing.

The Advantages of Using Purlin Roll Forming Machines

1. Efficiency The continuous production process of roll forming allows for high output levels. Manufacturers can produce purlins in bulk, significantly reducing labor costs and time.

purlin roll forming machine manufacturer

2. Precision Advanced purlin roll forming machines employ computerized controls to ensure that each purlin meets stringent specifications. This precision minimizes waste and enhances the overall quality of the product.

3. Customization Many modern purlin roll forming machines come equipped with features that allow for customization of dimensions and profiles. This adaptability means that manufacturers can respond swiftly to client needs without significant downtime.

4. Material Utilization Roll forming is known for its minimal waste generation. The process utilizes metal sheets efficiently, resulting in less scrap and making it a more environmentally friendly option compared to other manufacturing methods.

5. Durability Purlins produced using roll forming techniques tend to have superior strength and durability. The consistent thickness and uniformity ensure that these structural components can withstand the rigors of construction environments.

Choosing the Right Manufacturer

When considering the acquisition of a purlin roll forming machine, selecting a reputable manufacturer is crucial. The right manufacturer will offer machinery with robust features, backed by reliable customer service and technical support. They should also provide a comprehensive warranty and options for upgrades as technology evolves.

Manufacturers that specialize in roll forming machines often have the expertise to design custom solutions tailored to the specific needs of businesses, ensuring that clients achieve productivity and efficiency in their operations.

Conclusion

Purlin roll forming machines are at the forefront of modern manufacturing, providing essential support to the construction industry. Their ability to produce high-quality, custom purlins efficiently and with minimal waste is a testament to the advancements in manufacturing technology. As the construction sector continues to grow, investing in advanced purlin roll forming machines will undoubtedly yield substantial returns for manufacturers committed to quality and efficiency.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025