Top Manufacturers of Purlin Roll Forming Machines for Efficient Construction Solutions

The Evolution and Importance of Purlin Roll Forming Machine Companies

In the modern manufacturing landscape, the demand for efficient and versatile machinery is ever-growing. Among these essential machines are purlin roll forming machines, which play a crucial role in the construction and metal fabrication industries. Purlins serve as supportive elements in various structures, including commercial buildings, warehouses, and residential spaces. The rise of purlin roll forming machine companies is a testament to the importance of this equipment in today’s construction practices.

Understanding Purlin Roll Forming Machines

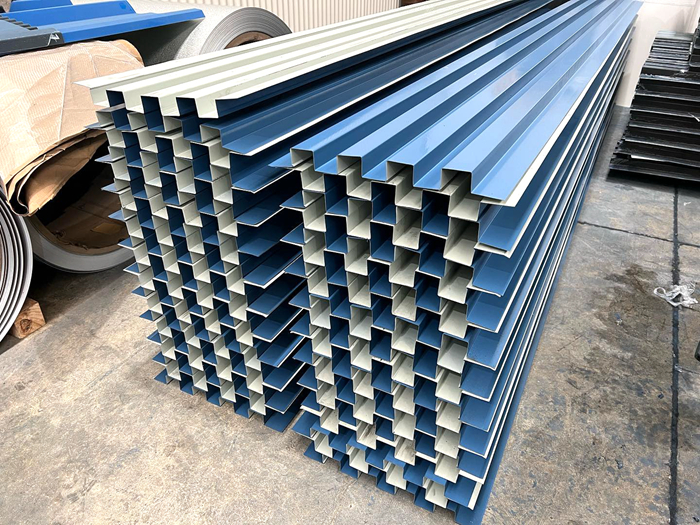

Purlin roll forming machines are specialized pieces of equipment designed to produce purlins—longitudinal beams that support a roof or wall. The machines work by feeding metal sheets, typically steel, into a series of rollers that shape the metal into specific profiles according to the required specifications. The process is continuous and automated, which allows for high production rates and consistent quality.

The main advantage of using a purlin roll forming machine is the ability to produce custom profiles tailored to particular projects without the need for extensive tooling changes. This flexibility not only saves time but also reduces material wastage, making the production process both economical and environmentally friendly.

The Growing Demand for Purlin Roll Forming Machines

As industries worldwide continue to embrace prefabrication and modular construction, the demand for purlin roll forming machines has surged. The construction sector is moving towards quicker, more efficient building methods, and purlin roll forming machines facilitate this transition. They provide manufacturers and builders with the capability to create lightweight, durable, and cost-effective structural components that meet modern building codes and standards.

Moreover, the construction of industrial buildings, warehouses, and agricultural structures has seen increased activity, driving demand for these machines. Companies that specialize in producing purlin roll forming machines have adapted to these industry trends by developing advanced models equipped with cutting-edge technology, such as computer numerical control (CNC) systems, which allow for precise control over the forming process.

Key Players in the Industry

purlin roll forming machine companies

Numerous companies have emerged as leaders in the purlin roll forming machine market. These manufacturers are dedicated to innovation and customer satisfaction, ensuring that their machines not only meet industry standards but also address specific client needs. Some notable companies have extensive experience in the industry, offering comprehensive support services, including installation, maintenance, and training.

These companies often feature a diverse range of products—ranging from standard purlin profiles to customized solutions for unique engineering challenges. Additionally, many manufacturers are focusing on sustainability, producing machines that minimize waste and energy consumption during operation.

Innovations in Purlin Roll Forming Technology

As technology advances, purlin roll forming machines are becoming more sophisticated. Innovations such as intelligent control systems, enhanced roller designs, and improved materials have increased the efficiency and output of these machines. Automated processes reduce the need for manual labor, further speeding up production and lowering costs for manufacturers.

Furthermore, the integration of Industry 4.0 technologies, including Internet of Things (IoT) capabilities, presents new possibilities for the market. These advancements enable manufacturers to monitor the performance of their machines in real-time, predict maintenance needs, and optimize production schedules based on demand.

Conclusion

The landscape of purlin roll forming machine companies is dynamic and rapidly evolving, driven by the growing needs of the construction and metal fabrication industries. As these machines become more advanced and efficient, the companies that manufacture them play a pivotal role in enabling faster, cost-effective, and sustainable building practices worldwide. By continuing to innovate and adapt to changing market demands, purlin roll forming machine companies will ensure their relevance and importance in the construction sector for years to come.

In summary, the significance of purlin roll forming machines in modern construction cannot be overstated, and the companies that build them are at the forefront of a critical industry transformation.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025