Purlin Roll Forming Machine for Efficient Metal Structure Production Solutions

Understanding the Purlin Roll Forming Machine A Key to Efficient Construction

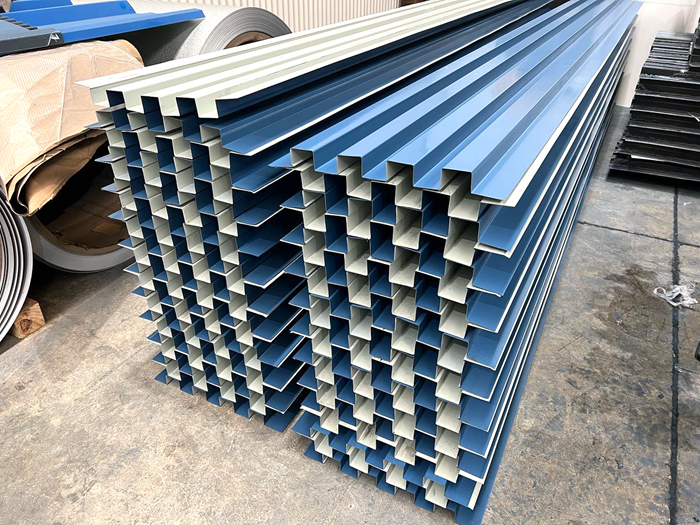

In the realm of modern construction, the purlin roll forming machine has emerged as a cornerstone for efficiency and precision. These machines are designed specifically to produce purlins—horizontal members that support roofs and walls in structural frameworks. Typically made from various materials such as steel or aluminum, purlins play an essential role in ensuring the robustness and stability of buildings.

What is a Purlin Roll Forming Machine?

A purlin roll forming machine is an advanced piece of equipment used to manufacture purlins through a continuous process. The machine operates by feeding flat metal sheets into a series of rollers, which gradually shape the sheets into the desired profile. The process not only streamlines production but also ensures uniformity and high precision in dimensions, which is critical in construction projects.

Advantages of Purlin Roll Forming Machines

1. Efficiency One of the most significant advantages of using a purlin roll forming machine is the efficiency it brings to the production process. These machines can produce large quantities of purlins in a relatively short time, making them ideal for projects with tight deadlines.

2. Customization Purlin roll forming machines can be easily adjusted to create various sizes and types of purlins to meet specific project requirements. This flexibility allows manufacturers to cater to a diverse range of construction needs.

3. Material Utilization The roll forming process minimizes waste, as it utilizes metal sheets efficiently. This not only reduces material costs but also contributes to more sustainable manufacturing practices, which is increasingly important in today's environmentally conscious market.

4. Durability and Strength The structural integrity of purlins produced by roll forming machines is often superior. The process enhances the strength of the metal through cold working, ensuring that the purlins can withstand heavy loads and environmental stresses.

5. Cost-Effectiveness While the initial investment in a purlin roll forming machine can be substantial, the long-term savings in labor, material waste, and production time make it a cost-effective solution for manufacturers and builders.

purlin rollforming machine

Applications of Purlins in Construction

Purlins are widely used in various construction applications, including residential, commercial, and industrial projects. They are commonly found in metal buildings, warehouses, factories, and agricultural structures. The versatility of purlins allows them to be used as roof supports or wall girts, effectively distributing loads and maintaining the structural integrity of the buildings.

Additionally, due to their lightweight nature, purlins made from roll-formed steel are easier to handle and install, which can further reduce labor costs and enhance safety on the job site.

How to Choose the Right Purlin Roll Forming Machine

When selecting a purlin roll forming machine, several factors should be considered

1. Production Requirements Assess the production volume and types of purlins needed. Machines with higher output capabilities may be required for large-scale operations.

2. Material Compatibility Ensure the machine can handle the specific materials you plan to use. Some machines are versatile enough to work with various metals, while others may be suited for specific materials.

3. Automation Features Consider whether you need a fully automated system or a semi-automated one. Greater automation can lead to increased efficiency but may also raise initial costs.

4. Support and Maintenance Choose a manufacturer that provides reliable support and maintenance services. Ensuring the longevity of your machinery is critical to maintaining consistent production levels.

In conclusion, the purlin roll forming machine plays a vital role in the construction industry, offering efficiency, customization, and durability. As the demand for modern building solutions continues to rise, investing in this technology can provide manufacturers and builders with a competitive edge, ensuring they meet the changing needs of the market while maintaining high standards of quality and performance.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025