Purlin Roll Forming Machine Manufacturers for Efficient Steel Structure Solutions

Purlin Roll Former Factories Engineered Excellence in Metal Fabrication

Purlin roll forming is a sophisticated manufacturing process that allows for the creation of C or Z-shaped purlins from sheets of metal, typically steel or aluminum. These purlins are essential components in the construction of buildings, offering structural support and durability. The purlin roll former factories play a crucial role in the metalworking industry, employing advanced technology to deliver high-quality products tailored to various construction needs.

Understanding Purlins

Purlins are crucial elements in the framework of many structures, acting as horizontal supports for roofing and siding. Their design can vary considerably, with C and Z-shaped purlins being the most commonly utilized. Such shapes not only enhance the structural integrity of buildings but also optimize material usage, making them a cost-effective choice for construction projects. Their robust nature makes them suitable for various applications, including commercial buildings, warehouses, and industrial structures.

The Role of Roll Forming

The roll forming process is essential for producing purlins efficiently and accurately. It involves feeding a coil of metal through a series of rollers, which gradually shape the metal into the desired profile. This continuous process minimizes waste and ensures consistency in dimensions, allowing for large-scale production while maintaining quality standards.

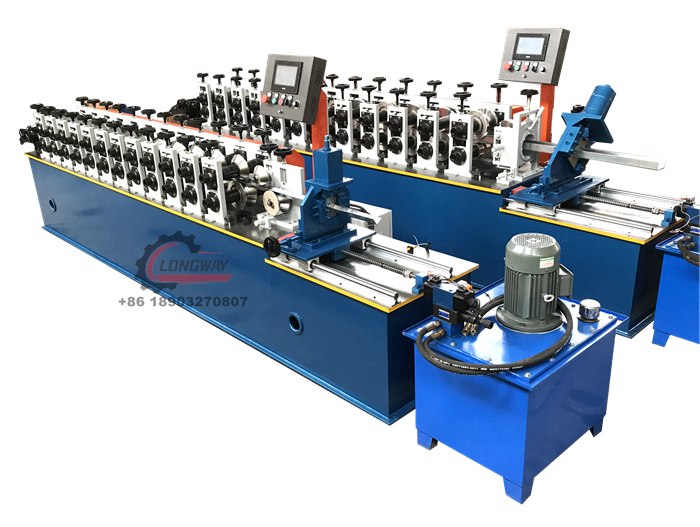

The machinery used in purlin roll forming is highly specialized. It includes various components such as decoilers, roll formers, cutting systems, and automatic controllers. These machines are designed to handle different thicknesses and types of metal, ensuring versatility in production. Moreover, modern roll formers are equipped with automation features that improve precision and reduce labor costs, making the manufacturing process more efficient.

The Advantages of Purlin Roll Former Factories

1. Customization Purlin roll former factories can produce purlins tailored to specific project requirements. Whether it’s a unique size, shape, or material type, manufacturers can adjust their processes to accommodate different specifications, enhancing flexibility in construction.

purlin roll former factories

2. Quality Assurance Factories employ rigorous quality control measures to ensure that every purlin meets industry standards. This includes inspections at various stages of the manufacturing process, from raw material sourcing to the final output. The emphasis on quality helps prevent issues in the field and reduces the likelihood of structural failures.

3. Cost Efficiency The roll forming process is inherently more efficient than traditional fabrication methods, which can lead to significant cost savings for both manufacturers and customers. By minimizing waste and maximizing speed, factories can offer competitive pricing without compromising quality.

4. Sustainability Many purlin roll former factories are moving towards more sustainable practices by recycling scrap metal and implementing energy-efficient processes. This commitment to sustainability not only benefits the environment but also enhances the company’s reputation in an increasingly eco-conscious market.

The Future of Purlin Roll Former Factories

As the demand for efficient and durable construction materials grows, purlin roll former factories are poised for further advancement. Innovations in technology, such as robotics and artificial intelligence, are being integrated into manufacturing processes to enhance productivity and precision. Additionally, as sustainable practices become more prominent, these factories are exploring ways to reduce their environmental footprint and promote eco-friendly manufacturing methods.

Moreover, the rise of modular construction and pre-engineered building systems may drive an increased demand for purlins, as these techniques often require precise and consistent components. This ongoing evolution in construction methodologies presents significant opportunities for purlin roll former factories to adapt and thrive.

Conclusion

Purlin roll former factories are at the forefront of modern metal fabrication, providing essential materials for the construction industry. Their commitment to quality, efficiency, and innovation ensures that they will continue to play a pivotal role in shaping the future of building design. As construction methodologies evolve and the demand for sustainable practices rises, these factories will undoubtedly adapt, cementing their importance in the ever-changing landscape of the construction sector.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025