purlin roll former company

The Role and Importance of Purlin Roll Former Companies in Modern Construction

In the ever-evolving construction industry, efficient and high-quality metal components are essential for building sturdy and sustainable structures. Among these components, purlins—horizontal structural elements that support the roof and walls of a building—play a critical role. Purlin roll former companies specialize in manufacturing purlins through advanced roll forming technology, catering to the growing demands of architects, engineers, and builders alike.

Understanding Purlins and Their Uses

Purlins are typically made from lightweight steel, often hot-dipped galvanized to resist corrosion and enhance durability. They come in various shapes, including C, Z, and U, each designed to serve specific structural purposes. Purlins are commonly used in commercial, industrial, and agricultural buildings, providing essential support for roofing systems and helping to maintain the structural integrity of the entire building.

The use of purlins simplifies the construction process. They provide a continuous line of support, making it easier for builders to install roofing panels, insulation, and other materials. Furthermore, purlins allow for efficient water drainage and air flow, contributing to the overall sustainability of a structure.

The Role of Purlin Roll Former Companies

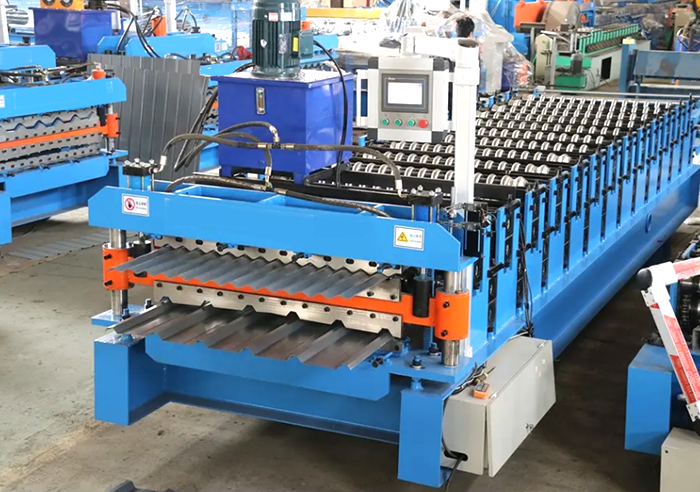

Purlin roll former companies utilize specialized machinery to create purlins from flat steel sheets. The roll forming process involves feeding the flat metal sheets through a series of rollers that progressively bend and shape the material into the desired profile. This manufacturing method ensures precision, consistency, and efficiency.

One of the critical advantages of using a purlin roll former company is the ability to customize purlins based on specific project requirements. Each construction project comes with its unique specifications, and these companies can adjust sizes, thicknesses, and shapes to meet these needs. Additionally, modern roll forming equipment is capable of producing purlins at high speeds, enabling manufacturers to meet tight deadlines without sacrificing quality.

purlin roll former company

Quality Assurance and Innovation

Leading purlin roll former companies prioritize quality assurance throughout the manufacturing process. They implement stringent quality control measures, testing the finished products for strength, durability, and dimensional accuracy. This commitment to quality helps builders avoid costly mistakes and ensures that the purlins will withstand the rigors of their intended applications.

Moreover, innovation is a key focus area for these companies. The construction industry is undergoing significant changes, with a growing emphasis on sustainability and energy efficiency. Purlin roll former companies are at the forefront of this shift, developing new materials and manufacturing techniques that reduce waste and improve the energy efficiency of buildings. For example, some companies are exploring the use of recycled steel and eco-friendly coatings, contributing to a greener construction process.

Customer-Centric Services

Purlin roll former companies recognize that their clients require more than just high-quality products. They often provide comprehensive services, including design consultation, logistics support, and after-sales service. By collaborating closely with architects, engineers, and contractors, these companies can ensure that their purlins meet the specific needs of each project.

Timely delivery is also a crucial aspect, as construction projects often face stringent schedules. Reputable purlin roll former companies are committed to delivering their products on time, allowing builders to maintain their project timelines.

Conclusion

In conclusion, purlin roll former companies play a vital role in modern construction, providing high-quality, customized purlins that support the structural integrity of various buildings. With a focus on quality assurance, innovation, and customer service, these companies are not only meeting the current demands of the industry but also paving the way for sustainable and efficient construction practices in the future. As the need for robust and reliable building materials continues to grow, purlin roll former companies are poised to be key players in shaping the skylines of tomorrow.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025