Metal Stud and Track Machine for Efficient Purlin Production Solutions

Understanding Purlin Metal Stud and Track Machines

In the realm of construction and structural engineering, the role of metal framing has gained significant importance over the years. Among the various components used in these structures, purlins and metal studs are essential in providing support and stability. The machines specifically designed for manufacturing these essential elements—known as purlin metal stud and track machines—are crucial for modern construction processes.

What are Purlins and Metal Studs?

Purlins are horizontal structural members used to support roofs and walls. They are integral to the stability of roof systems, providing a platform for the roofing materials. Metal studs, on the other hand, serve as the vertical framework for walls. They are an alternative to traditional wood framing and are favored for their durability, resistance to pests, and overall strength.

Metal stud framing systems are becoming increasingly popular in commercial and high-rise residential buildings, where they offer numerous advantages over traditional wood construction. Metal studs are lightweight, non-combustible, and resistant to warping, which makes them an attractive choice for architects and builders alike.

The Role of Purlin Metal Stud and Track Machines

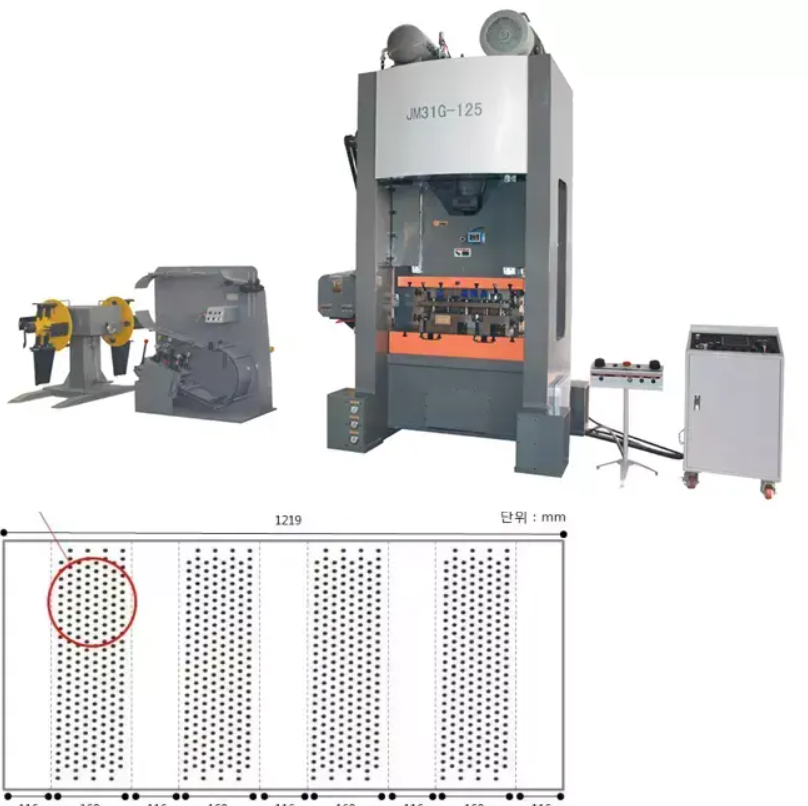

Purlin metal stud and track machines are advanced pieces of equipment designed to streamline the manufacturing process of these metal components. These machines are equipped to produce various profiles and shapes, allowing for custom solutions that meet specific design requirements.

Typically, a purlin metal stud and track machine operates using a cold-rolling process. This method involves taking a flat strip of metal and passing it through a series of rollers to shape it into the desired profile. This not only increases the efficiency of production but also ensures precision and consistency in the dimensions of the finished product.

Advantages of Using Purlin Metal Stud and Track Machines

purlin metal stud and track machine

1. Efficiency and Speed The automated nature of these machines significantly reduces the time required to produce metal studs and tracks. High-speed production means that large quantities can be manufactured quickly, meeting the demands of fast-paced construction projects.

2. Cost-Effectiveness By streamlining the manufacturing process, these machines can lower labor costs and decrease material waste. This results in considerable savings for construction companies, making metal framing a more economically viable choice.

3. Customizability Modern purlin metal stud and track machines can be programmed to produce various profiles and dimensions. This flexibility allows builders to create custom solutions tailored to the specific needs of their projects.

4. Quality Control Automated processes minimize human error, ensuring a high level of precision in manufacturing. This consistency in quality is crucial in ensuring structural integrity and safety.

5. Reduced Material Waste Advanced manufacturing techniques allow for more efficient use of materials, reducing waste and lowering overall environmental impact.

Conclusion

The development of purlin metal stud and track machines marks a significant advancement in the construction industry. By facilitating the efficient production of essential metal components, these machines play an integral role in modern building practices.

As the industry continues to evolve, the importance of utilizing sophisticated machinery for structural components will only grow. Builders and contractors who invest in purlin metal stud and track machines stand to benefit from improved efficiency, reduced costs, and superior product quality, thereby enhancing their competitive edge in the marketplace. In a world increasingly focused on sustainability and speed, these machines represent the future of construction and structural integrity.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025