Purlin Production Equipment Provider for Efficient Structural Solutions

Choosing the Right Purlin Making Machine Supplier

In the modern construction industry, efficient and reliable machinery is essential for streamlining processes and achieving higher productivity levels. One of the key components in building frameworks is the purlin, which acts as a support structure for roofs and walls. Consequently, selecting the right purlin making machine supplier is crucial for ensuring quality production and operational efficiency. This article explores the factors to consider when choosing a supplier for purlin making machines.

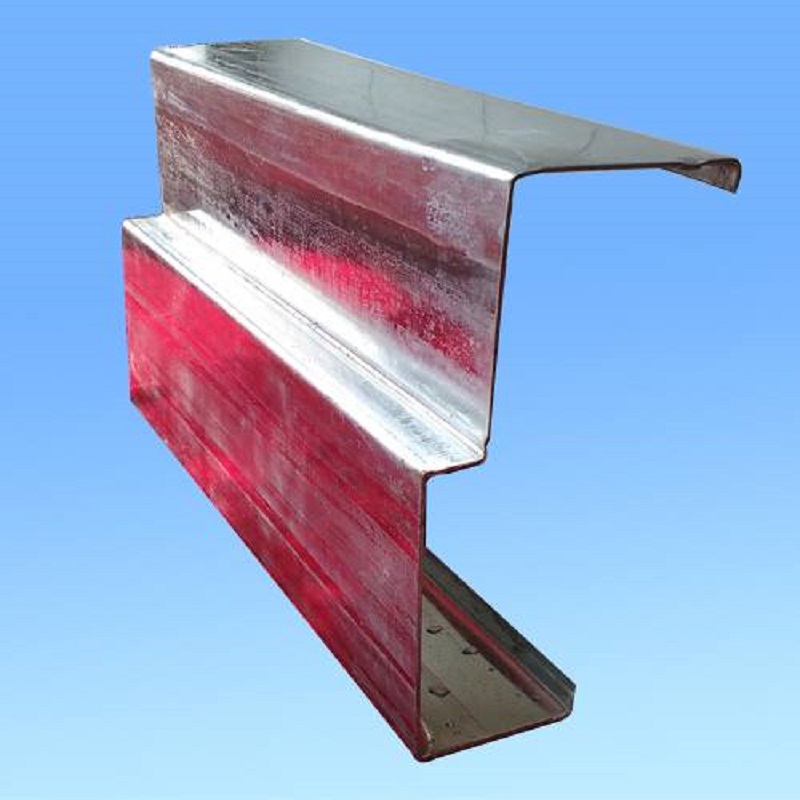

Understanding Purlin Machines

Purlin making machines are specialized equipment that shape and form metal into purlins used in various construction applications. These machines operate through a series of processes including cutting, bending, and welding metal strips into the desired profile. With advancements in technology, modern machines are often equipped with automation features that enhance precision and reduce manual labor, making them a valuable asset for construction businesses.

Reputation and Experience

When seeking a purlin making machine supplier, one of the first criteria to evaluate is the reputation of the company. Established suppliers with a proven track record are more likely to provide high-quality machines and excellent customer service. Researching the supplier's history, client testimonials, and case studies can provide insights into their reliability. Furthermore, experience in the industry is a key indicator of a supplier’s ability to meet specific needs and adapt to emerging technologies.

Quality and Technology

The quality of the machinery is paramount. A reputable supplier should offer machines that are built with high-grade materials and adhere to industry standards. It is advisable to inquire about the machine's manufacturing process, durability, and whether it comes with quality certifications. Additionally, suppliers that invest in technological advancements tend to provide better equipment. Automation features, user-friendly interfaces, and compatibility with various materials can considerably enhance productivity and efficiency.

purlin making machine supplier

Customization Options

Every construction project has unique requirements, and a one-size-fits-all approach may not be suitable. A good purlin making machine supplier should offer customization options to cater to specific client needs. This includes adjustments in the size and shape of purlins as well as modifications to the production capacity of the machine. The ability to customize machinery ensures that businesses can respond quickly to changing demand and remain competitive in the market.

Support and Service

Another vital aspect to consider is the level of support and after-sales service provided by the supplier. A reliable supplier should offer comprehensive training for operators, ongoing technical support, and regular maintenance services. Quick response times and effective problem-solving capabilities are essential, especially when downtime can lead to significant financial losses. Before making a decision, inquire about the manufacturer's warranty and the availability of spare parts to ensure that you are covered for any potential issues that may arise.

Cost Consideration

While it can be tempting to opt for the cheapest option, it’s crucial to consider the overall value rather than just the initial cost. Analyze the long-term benefits a higher-quality machine may bring, such as lower maintenance costs, greater efficiency, and improved output quality. Comparing several suppliers and their pricing structures will yield insights into where you can achieve the best return on investment.

Conclusion

Choosing the right purlin making machine supplier is a decision that can significantly impact your construction projects. Factors such as reputation, quality, customization options, support services, and cost should guide your decision-making process. By carefully evaluating suppliers, you can ensure the acquisition of high-quality machinery that enhances productivity and supports the growth of your business in the competitive construction landscape. Investing time in selecting the right partner will ultimately pave the way for successful project outcomes and long-term efficiency.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025