purlin machine factories

The Rise of Purlin Machine Factories Revolutionizing Steel Fabrication

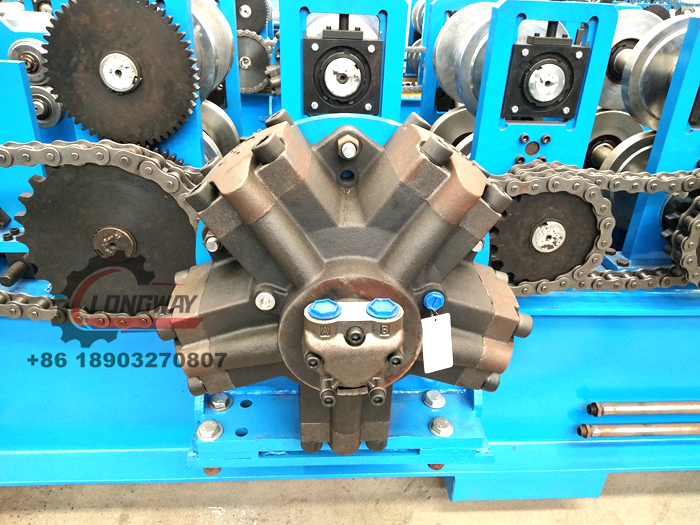

In the realm of modern construction and manufacturing, purlin machines have emerged as invaluable assets. These machines play a crucial role in producing purlins, which are structural components typically used in metal buildings and roof structures. The evolution of purlin machine factories has significantly transformed the efficiency, productivity, and overall quality of metal fabrication processes.

Purlins are horizontal structural elements that support the roof deck and are essential in the construction of buildings, warehouses, and storage units. Traditionally, purlins were manually fabricated, which was a time-consuming process that often led to inconsistencies and a high margin of error. However, with advancements in technology and the establishment of specialized purlin machine factories, the production of these elements has become streamlined and automated.

One of the key advantages of modern purlin machine factories is their ability to produce purlins of various shapes and sizes with remarkable precision. These factories utilize advanced machinery that can quickly adjust to different specifications, allowing manufacturers to cater to the diverse needs of their clients. The ability to produce custom purlins on-demand not only enhances efficiency but also reduces waste, as manufacturers can optimize material usage.

The automation of purlin production is another significant factor contributing to the rise of purlin machine factories. Automated systems reduce the reliance on manual labor, thus minimizing human error and enhancing safety in the workplace. Workers are now required to oversee and manage the machinery rather than engage in hazardous manual tasks. This shift not only improves the working environment but also allows for higher production rates, enabling manufacturers to meet increasing demands in a competitive market.

purlin machine factories

Moreover, the incorporation of computer numerical control (CNC) technology in purlin machinery has revolutionized the industry. CNC machines are capable of executing complex designs with exceptional accuracy, which was previously unattainable with manual methods. With this technology, fabricators can quickly produce intricate designs and replicate them consistently, ensuring uniformity across batches.

The geographical expansion of purlin machine factories is also noteworthy. With the rise of global construction activity, particularly in developing regions, the demand for high-quality purlins has surged. Countries with burgeoning construction markets have seen an influx of purlin machine factories aiming to meet this demand. As a result, local economies benefit from increased job opportunities and the development of a skilled workforce.

Furthermore, the eco-friendly aspect of modern purlin machine factories cannot be overlooked. These factories often adopt sustainable practices and utilize materials that are more environmentally friendly. By implementing recycling processes and efficient energy practices, purlin manufacturers are not only adhering to regulatory standards but also contributing to the broader goal of sustainability in construction.

In addition to the technical advancements, the competitive nature of the purlin manufacturing sector has pushed factories to innovate continually. This has led to the development of new production methods, materials, and technologies that enhance the performance of purlins. As construction projects strive for greater durability and resilience, purlin machine factories are at the forefront of these advancements, providing solutions that meet modern engineering standards.

In conclusion, purlin machine factories are a prime example of how technology and innovation can reshape an industry. By enhancing the efficiency of purlin production, ensuring the quality and precision of products, and promoting sustainability, these factories have become integral to the manufacturing landscape. As the construction industry continues to evolve, the role of purlin machine factories will undoubtedly grow, paving the way for a new era of steel fabrication that meets the demands of a rapidly changing world.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025