Purlin Production Equipment Manufacturers for Efficient Metal Fabrication Solutions

The Innovation and Importance of Purlin Forming Machine Companies

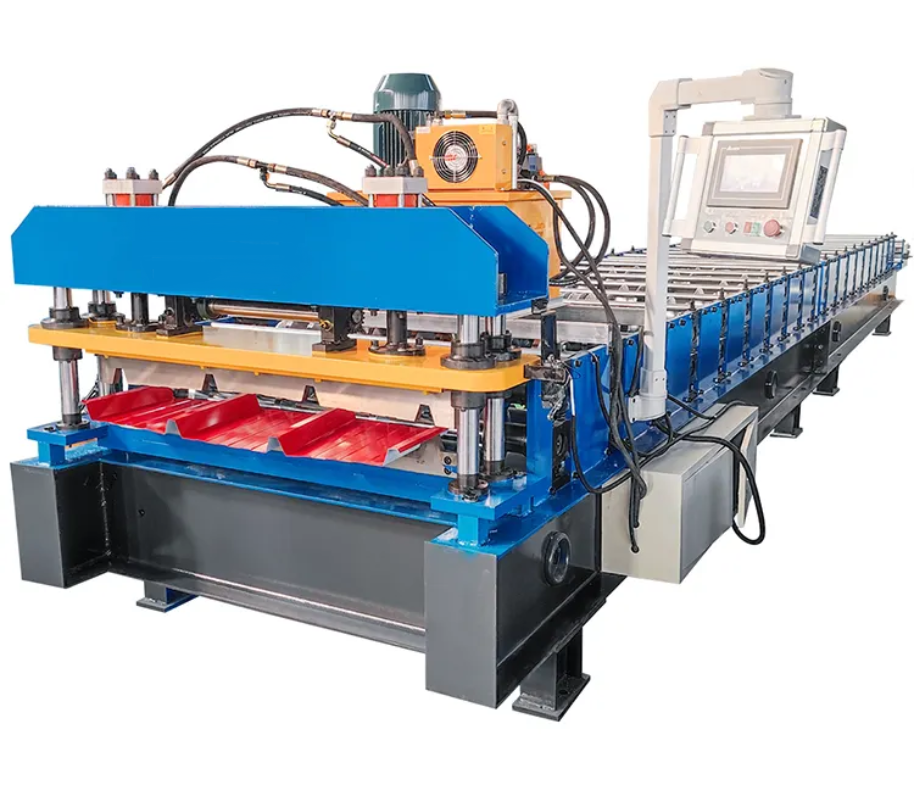

In the rapidly advancing world of construction and manufacturing, purlin forming machines have emerged as vital tools that enhance the efficiency and quality of metal framing systems. These specialized machines are instrumental in producing purlins, which are horizontal beams used in building construction to support roofing and wall panels. As the demand for durable and versatile building materials grows, purlin forming machine companies are stepping up to elevate industry standards and provide innovative solutions.

Understanding Purlin Forming Machines

Purlin forming machines are designed to manufacture metal purlins from steel or aluminum, employing a continuous roll-forming process. This entails feeding a flat strip of metal through a series of rollers that shape, cut, and form it into the desired profile. The final product can vary in size and thickness, making it suitable for diverse applications in commercial, industrial, and residential projects. There are several types of purlins, including C-purlins, Z-purlins, and Sigma purlins, each serving specific structural purposes.

The Role of Purlin Forming Machine Companies

Purlin forming machine companies play a crucial role in modern construction by offering advanced machinery and solutions tailored to the needs of fabricators and builders. These companies specialize in the design and production of purlin forming machines that incorporate state-of-the-art technology, ensuring precision and reliability. By investing in research and development, they continuously improve their machinery, allowing for faster operational speeds, better energy efficiency, and enhanced product quality.

Moreover, reputable purlin forming machine manufacturers provide comprehensive support services, including installation, training, and maintenance. This ensures that clients can maximize productivity and effectively troubleshoot any issues that may arise during operation. The emphasis on customer support strengthens the relationship between manufacturers and end-users, fostering a collaborative environment that promotes innovation.

Advantages of Modern Purlin Forming Machines

purlin forming machine company

The benefits of using modern purlin forming machines are numerous. Firstly, the automation and high-speed capabilities of contemporary machines significantly reduce production times, which is essential in today's fast-paced construction environment. This efficiency not only minimizes labor costs but also allows for quicker project turnaround, meeting increasing demand in the market.

Secondly, these machines offer greater design flexibility. Advances in technology permit the production of custom profiles to suit specific architectural needs, enabling designers and architects to explore creative solutions without compromising on structural integrity.

Additionally, modern purlin forming machines are equipped with sophisticated controls and monitoring systems. These features guarantee that each purlin meets stringent quality standards, providing consistency in dimensions and reducing waste material. As sustainability becomes increasingly important in construction, the ability to minimize waste is a significant advantage.

The Future of Purlin Forming Machines

The future of purlin forming machine companies looks promising, driven by technological advancements and changing market demands. As the construction industry leans more towards sustainable practices, manufacturers are focusing on developing more eco-friendly machines that utilize renewable energy sources and generate less waste. Furthermore, the integration of Industry 4.0 technologies, including IoT and artificial intelligence, is set to revolutionize the role of purlin forming machines in factories, enabling smarter production processes and predictive maintenance.

In addition, the global push for infrastructure development presents significant growth opportunities for purlin forming machine companies. Emerging markets in Asia, Africa, and Latin America are increasingly investing in construction, providing a fertile ground for innovative manufacturing solutions.

Conclusion

In conclusion, purlin forming machine companies are at the forefront of a dynamic industry, driving advancements in construction technology. With their commitment to quality, innovation, and customer satisfaction, these companies play a critical role in shaping the future of building materials and construction methods. As they continue to adapt to market trends and technological innovations, purlin forming machine manufacturers are poised to meet the demands of an evolving construction landscape, paving the way for a more modern and efficient approach to building infrastructure.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025