Efficient Purline Roll Forming Machines for High-Quality Steel Fabrication Solutions

The Evolution and Importance of Purline Roll Forming Machines

In the ever-evolving landscape of the manufacturing industry, the demand for precision, efficiency, and adaptability has never been higher. One of the critical technologies that have emerged to meet these demands is the purline roll forming machine. These machines play a pivotal role in producing purline, which is a vital component in the construction of steel structures, particularly in the building and roofing sectors.

Understanding Purline and Its Applications

Purlines are structural members that support roofing and wall systems, providing essential support for panels and other structural components. They are typically made from steel and come in various shapes and sizes, tailored to the specific needs of a project. Commonly used in the construction of warehouses, factories, and agricultural buildings, purlines are critical for ensuring the structural integrity and durability of these structures.

What is a Roll Forming Machine?

A roll forming machine is a type of equipment that continuously bends a long strip of metal into a desired cross-section, creating a series of shapes and profiles. This process typically involves feeding flat metal sheets through a series of rollers, each designed to incrementally shape the metal until it reaches the final form. The precision and uniformity achieved through this process make roll forming a preferred method for producing items like purlines.

Advantages of Purline Roll Forming Machines

1. High Efficiency One of the most significant advantages of purline roll forming machines is their ability to produce large quantities of purlines quickly. Once set up, these machines can operate continuously, allowing manufacturers to meet high demand without sacrificing quality.

2. Material Optimization Roll forming processes typically generate minimal waste, as the machinery can be designed to use the width of the metal sheet effectively. This feature is particularly important in an era where material costs can significantly impact the bottom line.

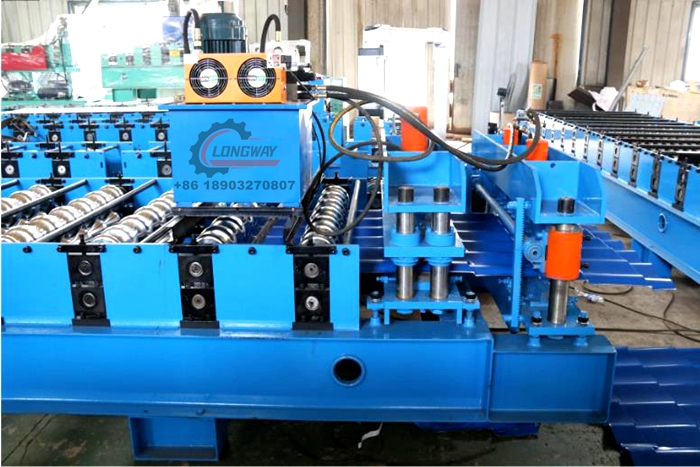

purline roll forming machine

3. Versatility Purline roll forming machines can be custom-built to produce various profiles, accommodating different specifications as needed for diverse construction projects. This adaptability makes them ideal for manufacturers looking to expand their product offerings.

4. Automation and Precision Modern roll forming machines often incorporate advanced technology, including computer numerical control (CNC) systems. This automation allows for precise engineering, reducing human error and ensuring that each purlin produced adheres to strict industry standards.

5. Durability and Strength The process of roll forming enhances the strength of the material. Metal is less likely to warp or bend under pressure when processed correctly, thus providing a robust product that's essential for construction.

Market Trends and Future Outlook

The global market for purline roll forming machines is on an upward trajectory, with growth driven by increasing construction activities, particularly in developing regions. The emphasis on sustainable building practices and the use of recyclable materials further contributes to the demand for steel structures, solidifying the role of purline in modern construction.

Moreover, advancements in technology are continuously improving the capabilities of roll forming machines. Features such as real-time monitoring, automated changeovers, and enhanced safety systems are being integrated to improve productivity and worker safety.

Conclusion

In summary, purline roll forming machines represent a crucial development in the manufacturing sector, particularly within the construction industry. Their ability to produce high-quality, durable purlines efficiently makes them indispensable for builders and engineers alike. As technology continues to advance, these machines will likely become even more sophisticated, enabling manufacturers to meet the growing demands for sustainable, efficient, and reliable construction solutions. The future of purline roll forming machines looks promising, with continued innovations on the horizon that will further enhance their relevance and utility in the modern marketplace.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025