profile sheet manufacturing machine factory

The Importance of Profile Sheet Manufacturing Machines in Modern Industries

In today’s rapidly advancing manufacturing landscape, profile sheet manufacturing machines play a vital role in various industries, including construction, automotive, and general manufacturing. These machines are designed to produce a variety of profile sheets, which are essential components that provide structural support, insulation, and aesthetic appeal to numerous applications. Understanding the significance of these machines and their applications can provide valuable insights into modern manufacturing processes.

What Are Profile Sheets?

Profile sheets are thin sheets of metal, often made from steel or aluminum, which are formed into specific shapes that enhance their physical and aesthetic properties. Common types of profile sheets include roofing sheets, wall cladding sheets, and flooring sheets. These products are fabricated using specialized machines that form them into desired profiles, ensuring both strength and lightweight characteristics. The variety of applications makes profile sheets a critical element in construction projects, ranging from residential buildings to industrial facilities.

The Manufacturing Process

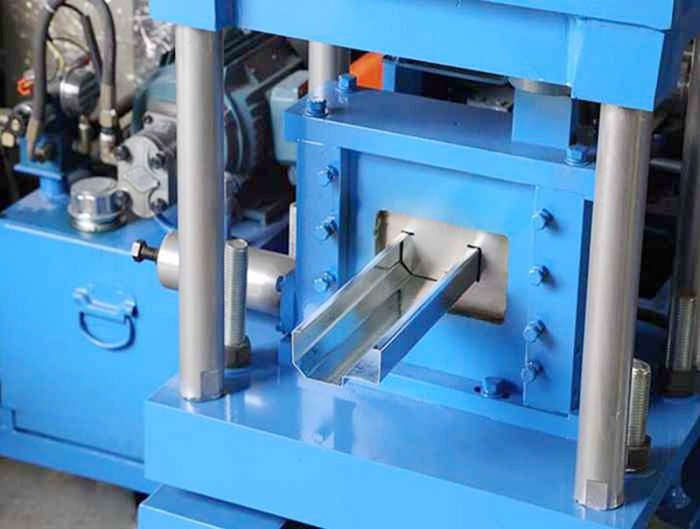

The manufacturing of profile sheets involves several key stages that require precision engineering and automation. The process typically begins with raw materials being fed into a roll forming machine. This machine consists of several rollers that progressively shape the metal sheets into desired profiles. The operation is highly efficient, allowing for continuous production while maintaining tight tolerances on dimensions.

After forming, the sheets often undergo various treatments, including cutting, drilling, and finishing processes. This may involve the application of coatings to improve durability and resistance to weather and corrosion. The final product is then ready for dispatch or further assembly, depending on the end use.

Key Features of Profile Sheet Manufacturing Machines

1. Automation and Precision Modern profile sheet manufacturing machines are equipped with advanced automation technology, allowing for consistent and precise production. CNC (Computer Numerical Control) technology is often employed to enhance accuracy and reduce labor costs.

2. Versatility These machines can produce a wide range of profiles and thicknesses, making them suitable for diverse applications. Manufacturers can easily switch between different profiles, enabling them to meet specific client requirements efficiently.

profile sheet manufacturing machine factory

3. Efficiency With the ability to produce large quantities in a continuous manner, these machines significantly enhance productivity. As a result, manufacturers can meet market demand swiftly and efficiently, reducing lead times.

4. Durability and Maintenance High-quality manufacturing machines are built to withstand rigorous production demands. They often feature robust construction and materials that minimize the frequency of repairs and downtime.

Industry Applications

Profile sheets manufactured by these machines are widely used in various sectors

- Construction Profile sheets serve as roofing and wall cladding materials, offering both protection and aesthetic value. Their lightweight yet durable nature makes them ideal for modern architectural designs.

- Automotive In the automotive industry, profile sheets are utilized for manufacturing the bodywork of vehicles. Their strength-to-weight ratio contributes to improved fuel efficiency and safety.

- Furniture and Appliances Profile sheets are also involved in the manufacturing of furniture and appliances, where they are used for creating functional and decorative components.

Conclusion

In conclusion, profile sheet manufacturing machines are indispensable in modern industry, providing the necessary means to produce essential components for a variety of applications. Their capabilities in terms of automation, precision, and efficiency enable manufacturers to meet the demands of an ever-evolving market. As industries continue to advance, the significance of these machines will only grow, reinforcing their role in promoting innovation and sustainability in manufacturing practices. Investing in high-quality profile sheet manufacturing machines will undoubtedly contribute to the success of manufacturing enterprises in the future.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025