profile sheet machine manufacturer

Profile Sheet Machine Manufacturer Enhancing Industrial Capabilities

In the ever-evolving landscape of manufacturing, the demand for precise and efficient machinery is paramount. Among the many specialized machines designed to meet specific industry needs, profile sheet machines stand out due to their versatility and utility across various sectors. These machines are essential for producing metal sheets with specific profiles that cater to the construction, automotive, and various other industries. This article will delve into the significance of profile sheet machine manufacturers, their offerings, and the impact of their innovations on industrial applications.

Understanding Profile Sheet Machines

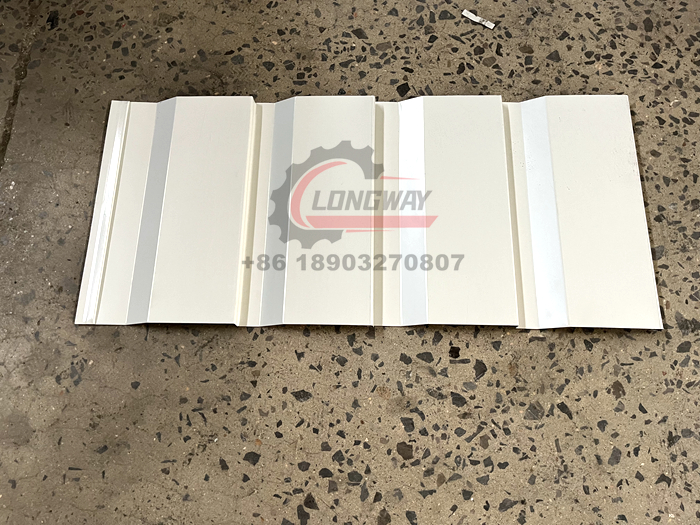

Profile sheet machines are crafted to produce metal sheets that have specific profiles, shapes, and thicknesses tailored to various applications. Commonly made from materials like steel, aluminum, and copper, profile sheets are used in roofing, wall cladding, and even automotive components. The manufacturing process involves several stages, including feeding, forming, cutting, and stacking, which are all handled by the machine with precision and efficiency.

The Role of Manufacturers

Profile sheet machine manufacturers play a crucial role in the manufacturing ecosystem. They focus on designing and producing high-quality machinery capable of meeting the rigorous demands of the industry. The complexity of modern manufacturing requires that these machines are not only robust and reliable but also equipped with the latest technology for automation and control.

1. Innovation and Technology Leading manufacturers invest significantly in research and development to create machines that utilize advanced technologies. Features such as computer numerical control (CNC) allow for enhanced precision and repeatability, which is vital for maintaining quality in mass production. Furthermore, automation facilitates faster production rates and reduced labor costs, a crucial factor in today’s competitive market.

2. Customization Each industry has unique requirements; thus, the ability to tailor machines to specific needs is essential. Profile sheet machine manufacturers often offer customized solutions, allowing clients to modify parameters such as sheet thickness, width, and profile shape. This adaptability ensures that manufacturers can meet diverse customer specifications effectively.

profile sheet machine manufacturer

3. Quality Assurance Quality control is fundamental in the manufacturing of profile sheet machines. Reputable manufacturers implement strict quality assurance processes throughout the production cycle, from the selection of raw materials to the final assembly. This commitment to quality not only enhances the durability and performance of the machinery but also instills confidence in their clients.

Impact on Industries

The machines produced by profile sheet manufacturers have a far-reaching impact on various industries. In construction, for example, profile sheets are used in roofing systems that provide durability and energy efficiency. In the automotive sector, these sheets contribute to lightweight designs, improving fuel efficiency without compromising safety.

Moreover, the efficiency of profile sheet machines translates to lower production costs and faster project turnaround. In an environment where speed and cost management are key, the role of these machines becomes even more critical. Businesses can scale their operations more effectively, respond quickly to market demands, and maintain a competitive edge.

Future Trends

As industries continue to evolve, profile sheet machine manufacturers are likely to adapt to new trends that emphasize sustainability and energy efficiency. The future may see innovations like the integration of renewable energy sources to power machines or the development of eco-friendly materials for profile sheets. Additionally, advancements in Industry 4.0 technologies, such as IoT and machine learning, can lead to smarter manufacturing processes that enhance productivity and reduce waste.

Conclusion

In conclusion, profile sheet machine manufacturers are essential players in the industrial manufacturing landscape. By producing specialized machinery that ensures precision, efficiency, and adaptability, they not only cater to diverse industry needs but also drive innovation and sustainability. As the demand for high-quality profile sheets continues to grow, these manufacturers will play a pivotal role in shaping the future of various sectors, promoting efficiency, and enhancing the quality of industrial output. The continuing evolution of technology will further empower them to meet the challenges of tomorrow, ensuring that they remain a cornerstone of the manufacturing industry.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025