profile forming machine manufacturers

The Importance of Profile Forming Machine Manufacturers in Modern Manufacturing

In a rapidly evolving industrial landscape, the role of profile forming machine manufacturers has gained unparalleled significance. As industries strive for efficiency, precision, and customization, these manufacturers stand at the forefront, providing innovative solutions tailored to meet the diverse needs of various sectors. This article delves into the importance of profile forming machines, the manufacturers behind them, and the impact they have on modern manufacturing processes.

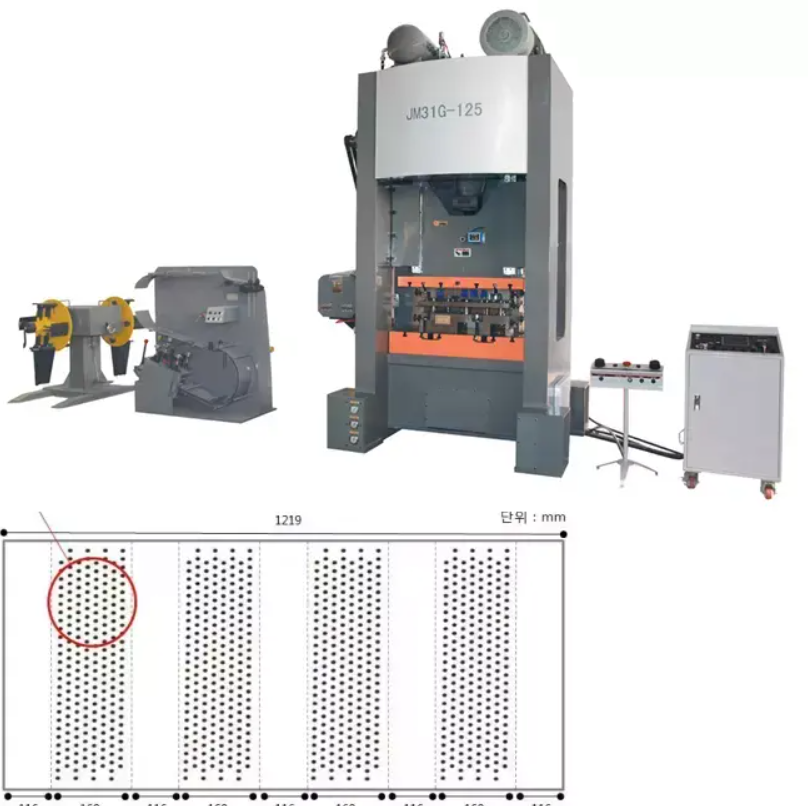

Understanding Profile Forming Machines

Profile forming machines, often referred to as roll forming machines, are sophisticated pieces of equipment designed to create a variety of profiles from metal sheets and strips. These machines work by passing the material through a series of rollers that gradually shape it into the desired profile. The versatility of these machines allows for the production of components that are used in construction, automotive, appliances, and more. Common applications include roof trusses, wall panels, door frames, and various structural elements.

The Role of Manufacturers

Profile forming machine manufacturers are essential in the production chain. They design, develop, and produce these machines based on industry requirements and specifications. The manufacturing process itself is a complex blend of engineering, design, and materials science. Renowned manufacturers employ cutting-edge technology to ensure that their machines deliver high precision, durability, and efficiency.

1. Innovation and Technology One of the defining traits of leading profile forming machine manufacturers is their commitment to innovation. They continually integrate new technologies to enhance machine performance. Automation, for instance, has revolutionized the industry, allowing for faster production speeds and reduced labor costs. Moreover, manufacturers invest in Research & Development (R&D) to explore new materials and processes, ensuring that their machines stay ahead of the curve.

2. Customization and Flexibility Different industries have unique requirements, necessitating a one-size-fits-all approach is no longer viable. Profile forming machine manufacturers excel in offering customization options. They work closely with clients to design machines that meet specific project needs, be it in terms of size, shape, or production volume. This flexibility not only improves the end-product quality but also enhances operational efficiency by minimizing waste and maximizing output.

profile forming machine manufacturers

3. Quality Assurance The quality of the final product largely depends on the machinery utilized in its production. Reputable manufacturers prioritize quality control, implementing rigorous testing procedures to ensure reliability and performance. Their commitment to high manufacturing standards translates to machines that are not only effective but also long-lasting. This focus on quality helps industries avoid costly downtime and maintenance issues, ultimately boosting productivity.

4. Sustainability In an era where sustainability is paramount, profile forming machine manufacturers are actively seeking ways to minimize their environmental footprint. Modern machines are designed to optimize resource use, reducing material waste and energy consumption during production. This aligns with global trends towards eco-friendly manufacturing practices, making these machines an attractive option for companies committed to sustainability.

The Impact on the Industry

The influence of profile forming machine manufacturers extends beyond just producing machinery; they play a crucial role in shaping the efficiency and effectiveness of various industries. By facilitating the mass production of high-quality components, these manufacturers enable businesses to scale up operations while maintaining competitive pricing.

Moreover, the versatility of profile forming machines allows for rapid prototyping and small-batch productions, catering to the growing demand for customization in many sectors. This adaptability is particularly vital in industries like aerospace and automotive, where innovation cycles are short, and consumer preferences evolve swiftly.

Conclusion

In conclusion, profile forming machine manufacturers are indispensable players in the modern manufacturing landscape. Their commitment to innovation, customization, quality assurance, and sustainability has led to more efficient and cost-effective production processes. As industries continue to evolve and face new challenges, the importance of these manufacturers will only grow, making them vital partners in the quest for excellence in production. The future of manufacturing undoubtedly hinges on the advancements and solutions they provide, shaping how components are produced, and setting the stage for a more advanced industrial era.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025