Understanding the Cost Factors of Roll Forming Machines for Your Business Needs

Understanding the Cost of Roll Forming Machines A Comprehensive Overview

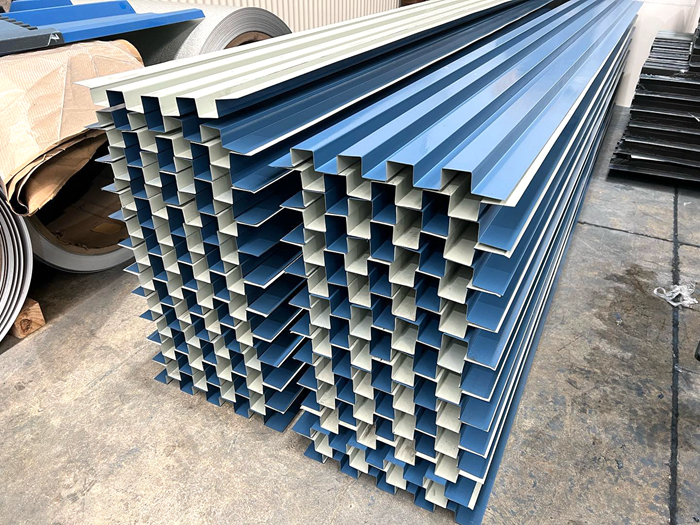

Roll forming machines are essential in the manufacturing sector, particularly in industries requiring long runs of metal products such as roofing, panels, and various structural components. The cost of these machines can vary significantly based on numerous factors, making it crucial for businesses to comprehend what influences these price changes.

What is a Roll Forming Machine?

A roll forming machine is a type of machinery that utilizes a continuous bending operation to shape metal into desired profiles. The process involves feeding a strip of metal through a series of rollers that gradually form the metal into the final shape. This method is highly efficient for producing consistent and uniform shapes, making it a preferred choice for mass production.

Factors Influencing the Price

1. Type of Machine The primary determinant of the price of a roll forming machine is the type of machine itself. There are several varieties, including manual, semi-automatic, and fully automatic machines. - Manual machines tend to be less expensive, with prices starting around $10,000, but they require more labor and are less efficient. - Semi-automatic machines offer a balance between cost and productivity, with prices ranging from $20,000 to $50,000. - Fully automatic systems, which include advanced features like automated adjustments and digital controls, can cost anywhere from $50,000 to over $200,000, depending on their complexity and the technologies involved.

2. Material and Thickness The type of metal being processed and its thickness can significantly impact the machine cost. Machines designed to handle thicker or harder materials generally require more robust components and motor power, thereby increasing the price.

price of roll forming machine

3. Customization Needs Custom roll forming machines that are tailored to produce specific profiles or shapes tend to be more costly than standard models. The design and engineering required for such machines add to the overall expenses, often resulting in costs well above $100,000.

4. Technology and Features Modern roll forming machines integrate advanced technologies such as programmable logic controllers (PLCs), servo drives, and enhanced safety features. Machines equipped with these technologies typically have higher price tags but also offer improved efficiency, precision, and ease of operation.

5. Brand and Manufacturer Reputation The reputation of the manufacturer can also play a significant role in the machine's cost. Reputable brands with a proven track record of reliability and quality often charge a premium for their machines. In contrast, lesser-known manufacturers may offer lower prices but may compromise on performance and after-sales support.

6. After-Sales Service and Support The availability of good after-sales service and customer support is another aspect that can affect the cost. A manufacturer providing robust customer service, maintenance support, and training may have higher prices, which can be justified by the long-term benefits of reduced downtime and operational efficiency.

Conclusion

Investing in a roll forming machine is a significant decision that requires careful consideration of multiple factors influencing its price. Businesses need to evaluate their production requirements, budget constraints, and the importance of features like automation and customization. While the initial investment may seem substantial, a high-quality roll forming machine can provide significant returns through increased efficiency, reduced labor costs, and improved product quality.

Ultimately, understanding the cost of roll forming machines entails more than just comparing price tags; it includes evaluating the overall value these machines bring to the organization in terms of productivity and growth potential. By making informed decisions, businesses can ensure that they choose the right machine that not only fits their budget but also supports their long-term manufacturing goals.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025