Precision Roll Forming Equipment Manufacturer for High-Quality Metal Fabrication Solutions

Precision Rollformers Factory Crafting Excellence in Metal Fabrication

In the ever-evolving landscape of manufacturing, the precision rollformer factory stands out as a haven of innovation and quality. This specialized manufacturing facility focuses on the process of roll forming, where metal sheets and strips are transformed into high-precision components through a series of continuous bending operations. The significance of this process can be seen across various industries, from construction to automotive and beyond. Let’s delve into the intricacies of a precision rollformers factory, exploring its operations, benefits, and impact on the modern manufacturing ecosystem.

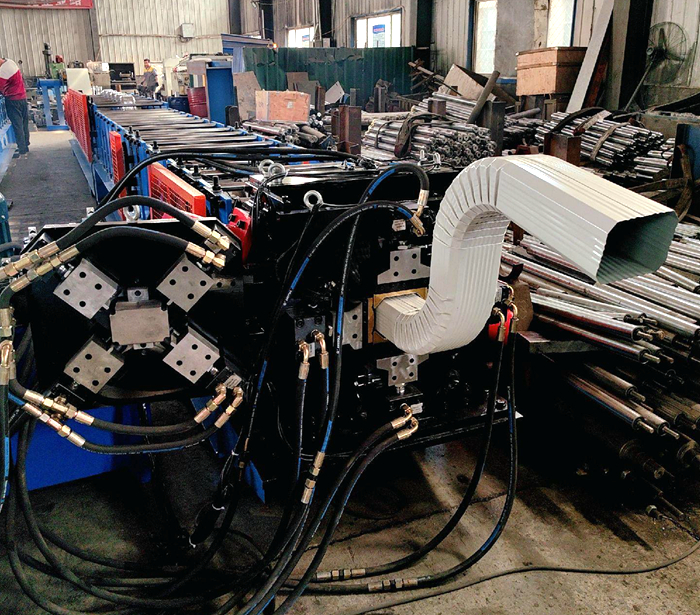

At the heart of any precision rollformer factory lies the sophisticated machinery designed for exceptional performance. Roll forming machines are engineered to bend metal in a continuous motion, using a series of rollers to achieve the desired shapes. The precision in the roll forming process is paramount. Each roller is meticulously designed to ensure that the metal is shaped accurately, maintaining uniform thickness and dimensions. This attention to detail is crucial, as even minor deviations can lead to significant quality issues in the final product.

One of the primary advantages of precision roll forming is its efficiency. Unlike traditional metal forming processes that may require multiple setups and handlings, roll forming allows for high-volume production with minimal waste. The continuous nature of the process means that manufacturers can produce long lengths of metal components in a single run. This efficiency not only reduces production costs but also accelerates delivery times, which is a vital factor in today’s fast-paced market.

Moreover, the versatility of roll forming is unmatched. A precision rollformer factory can create an extensive array of shapes and profiles, catering to the specific needs of various industries. Whether it’s creating metal studs and tracks for construction, specialized brackets for the automotive industry, or custom profiles for specialized machines, the possibilities are virtually limitless. This flexibility is bolstered by advanced computer-aided design (CAD) technology, enabling engineers to design complex components with precision before they even enter the production phase.

precision rollformers factory

Quality control is a cornerstone of operations in a precision rollformer factory. Manufacturers utilize rigorous testing protocols to ensure every product meets stringent industry standards. This includes real-time monitoring during production and post-production inspections. With the implementation of advanced technologies such as laser measurement and feedback systems, manufacturers can quickly identify and rectify potential issues, ensuring that the finished products not only meet but exceed customer expectations.

Sustainability is another crucial aspect of modern manufacturing, and precision rollformers are no exception. Many factories are adopting eco-friendly practices, including recycling scrap metal and optimizing energy use throughout the production process. By focusing on sustainability, these factories not only reduce their environmental impact but also appeal to a market that increasingly values corporate responsibility.

Looking towards the future, the role of technology in precision rollforming is set to expand even further. The integration of automation and robotics into the production line promises enhanced efficiency and precision. Machine learning and IoT (Internet of Things) technologies will allow factories to gather data and analyze production processes in real-time, leading to continuous improvement and innovation. As these advancements unfold, precision rollforming will remain at the forefront of metal fabrication, continuously adapting to meet the diverse needs of its clientele.

In conclusion, a precision rollformers factory embodies the spirit of modern manufacturing. Through a combination of advanced technology, exceptional quality control, and sustainable practices, these factories play a pivotal role in producing essential components that drive various industries. As the demand for high-quality metal products continues to rise, the precision rollformer factory stands ready to meet the challenges of the future, crafting excellence in every roll formed piece. Embracing innovation while adhering to the highest standards of quality, these factories ensure that they remain integral contributors to the dynamic landscape of global manufacturing.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025