portable roof panel machine factory

The Evolution and Importance of Portable Roof Panel Machine Factories

In an era where efficiency and mobility are paramount in the manufacturing sector, portable roof panel machine factories have emerged as essential players in the construction industry. These state-of-the-art facilities are designed to produce high-quality roofing panels on-site, thereby minimizing transportation costs and enhancing project timelines. This article delves into the significance of portable roof panel machines, their operational mechanisms, and the immense benefits they offer to builders and contractors.

Innovations in Portable Roof Panel Machinery

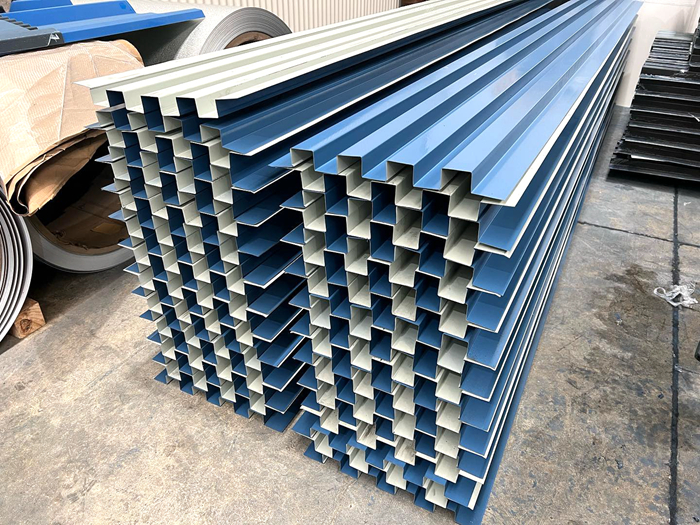

Portable roof panel machines are innovative pieces of equipment that can fabricate roofing panels of various materials, including metal and polymers, directly at the construction site. These machines employ advanced technologies such as computer numerical control (CNC) and automated protocols, ensuring that roofs can be manufactured with precision. The portability of these machines means they can be easily transported to different job sites, allowing for rapid production that aligns with the fast-paced demands of modern construction.

The design of these machines is particularly user-friendly, enabling operators to quickly set up and begin production. With customizable settings, operators can modify panel dimensions, thickness, and profiles based on project specifications. This flexibility is crucial in a market where clients often require tailored solutions to meet specific aesthetic and structural needs.

Benefits to the Construction Industry

One of the most significant advantages of utilizing portable roof panel machines is the reduction in lead times. Traditional methods of roofing panel production typically involve off-site manufacturing, which can result in delays due to shipping and handling. By producing panels on-site, construction companies can adhere to tighter schedules, reducing downtime and preventing cost overruns.

portable roof panel machine factory

Moreover, the on-site fabrication of roofing panels allows for better quality control. Since panels can be produced in direct response to job site conditions, they can be made to fit perfectly, thereby minimizing waste and ensuring superior structural integrity. This aspect is particularly important for complex architectural designs where precision is paramount.

Additionally, the mobility of these factories greatly enhances a company's capability to service remote or challenging locations. In situations where access to standard manufacturing facilities is limited, portable roof panel machine factories ensure that high-quality roofing solutions can still be produced, effectively bridging the gap between demand and supply.

Environmental Impact and Sustainability

Sustainability is another critical consideration for modern manufacturers. Portable roof panel machines support greener practices by reducing transportation emissions associated with long-distance shipping of pre-fabricated panels. Furthermore, the ability to optimize material usage on-site translates to less waste, aligning with the construction industry's increasing emphasis on eco-friendly building practices.

Manufacturers of these machines are continually pushing the boundaries of efficiency, integrating energy-efficient technologies that lower the carbon footprint of the production process. As construction projects increasingly prioritize sustainability, the adoption of portable roof panel machines represents a step towards more responsible building practices.

Conclusion

In conclusion, portable roof panel machine factories have revolutionized the construction industry by combining efficiency, flexibility, and sustainability. Their ability to produce high-quality roofing solutions on-site addresses many of the challenges faced by traditional construction methods, including time delays, cost overruns, and quality inconsistencies. As the industry continues to evolve, embracing these cutting-edge technologies will be crucial for builders and contractors aiming to meet the expectations of a fast-paced, eco-conscious marketplace.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025