Portable Roll Forming Machines for Sale from Leading Manufacturers and Suppliers

Portable Roll Forming Machines for Sale A Comprehensive Overview

In the world of construction and manufacturing, the need for efficient and cost-effective solutions has led to the rise of portable roll forming machines. These machines provide a unique advantage by allowing manufacturers to produce metal profiles on-site, thus reducing transportation costs and ensuring quality control. This article explores the features, benefits, and leading manufacturers of portable roll forming machines available for sale.

What is a Portable Roll Forming Machine?

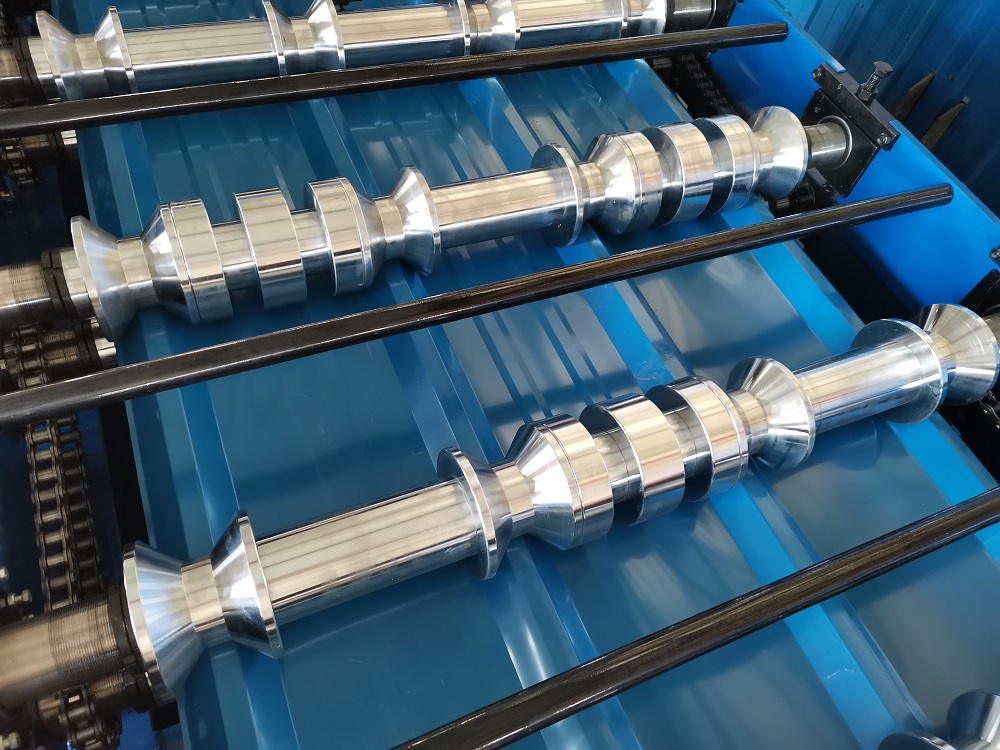

A portable roll forming machine is a compact, mobile device used to produce a variety of metal profiles from coiled metal sheets. The materials commonly processed include steel, aluminum, and other alloys. These machines work by feeding metal sheets through a series of rollers that gradually shape the material into the desired profile such as roof panels, wall panels, and various types of gutters.

Key Features

1. Mobility The most significant feature of these machines is their portability. Many manufacturers design them to be lightweight and compact, enabling easy transportation to construction sites. 2. User-Friendly Operation Most modern portable roll forming machines come with digital controls, making it easy for operators to set parameters and monitor production. This simplicity helps reduce the learning curve for new users.

3. Versatility Portable roll forming machines are capable of producing a wide range of profiles. This adaptability makes them suitable for various industries, including construction, automotive, and HVAC.

4. Durability Built to withstand harsh operating conditions, these machines are typically made from high-quality materials. This ensures longevity and reliability, which is essential for on-site work.

Benefits of Using Portable Roll Forming Machines

1. Cost-Effective Production By producing metal profiles on-site, companies can significantly reduce material waste and eliminate shipping costs. This leads to enhanced profitability and resource management.

portable roll forming machine for sale manufacturer

2. Customization On-site manufacturing enables companies to tailor metal profiles to specific project requirements quickly. This flexibility can lead to faster project turnaround times and improved customer satisfaction.

3. Reduced Lead Times With portable roll forming machines, the need for pre-fabricated parts is diminished. This allows for quicker response times to project changes or client demands.

4. Improved Quality Control Producing materials on-site allows for immediate inspection and adjustments, ensuring that the final products meet quality standards.

Leading Manufacturers

When considering the purchase of a portable roll forming machine, it’s essential to evaluate top manufacturers in the industry. Companies such as MCK, HCI, and Bradbury have established themselves as reliable providers, known for offering durable machines with excellent customer service.

- MCK Specializes in streamlined roll forming solutions, focusing on customer specifications and innovative technology.

- HCI Offers a diverse range of portable machines tailored for different applications, from roofing to framing.

- Bradbury Well-known for their durability and user-friendly designs, Bradbury's machines are highly regarded in the construction sector.

Conclusion

Investing in a portable roll forming machine can be a game-changer for construction and manufacturing businesses. With their numerous benefits, including cost savings, enhanced productivity, and superior control over the manufacturing process, these machines are rapidly becoming an essential tool in the industry. As technology continues to evolve, we can expect even more innovative solutions from manufacturers, further solidifying the role of portable roll forming machines in modern construction. Whether you are a small contractor or a large corporation, evaluating your needs and understanding the available options will help you make an informed decision that enhances your operational efficiency.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025