portable roll former company

The Rise of Portable Roll Former Companies Revolutionizing Metal Fabrication

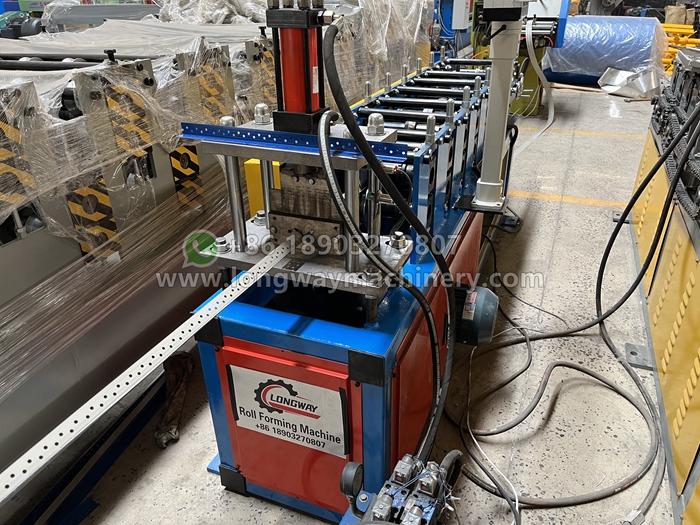

In recent years, the metal fabrication industry has witnessed a significant transformation, largely due to the emergence of portable roll former companies. These companies specialize in producing portable roll-forming machines that allow manufacturers to create metal profiles on-site, eliminating the need for transporting bulky materials or investing in large infrastructure. This innovation has not only streamlined production processes but also opened up new avenues for efficiency and flexibility in a variety of industries, including construction, automotive, and HVAC.

What is Portable Roll Forming?

Portable roll forming is a process in which metal sheets, usually steel or aluminum, are fed into a machine that shapes them into specific profiles through a series of rollers. Unlike traditional roll forming, which occurs in fixed locations, portable roll forming allows businesses to move the machinery directly to the worksite. This has significant implications for logistics, cost efficiency, and project timelines.

Benefits of Portable Roll Former Companies

1. Increased Flexibility One of the primary advantages of portable roll forming is its flexibility. Businesses can now produce custom profiles tailored to specific project requirements, reducing lead times and improving responsiveness. This is especially beneficial for construction companies that often face changing project specifications.

2. Cost-Effective Production By allowing manufacturers to create materials on-site, portable roll formers help minimize costs related to transportation and waste. Companies can produce exactly what they need, when they need it, thus optimizing material utilization and reducing excess inventory.

3. Improved Quality Control With the ability to manufacture on-site, companies have greater control over the production process. They can quickly address any issues that arise, ensuring that the end product meets quality standards. This is particularly advantageous in industries where precision and quality are paramount.

portable roll former company

4. Enhanced Safety and Reduced Risk Transporting large metal sheets can pose significant safety risks, from injuries incurred during handling to potential damage during transport. Portable roll forming reduces these risks by allowing companies to manage the entire process closer to the installation site, thereby enhancing overall safety.

5. Sustainability Reducing the need for transportation not only cuts costs but also lowers the carbon footprint associated with manufacturing processes. As industries increasingly move toward sustainable practices, the adoption of portable roll formative technology aligns with environmental goals.

Innovations in Portable Roll Forming Technology

As the demand for portable roll forming solutions grows, companies are continually innovating their machinery to enhance capabilities. Modern machines are becoming more automated, with features that allow for quick changeovers between different profiles. This increases productivity and allows businesses to take on a wider variety of projects.

Additionally, advancements in materials and design are leading to more lightweight yet durable machines, making it easier for companies to transport and set up their equipment. Some manufacturers are also incorporating digital technology, enabling remote monitoring and control of the machines, which facilitates real-time adjustments and data collection for better performance analysis.

The Future of Portable Roll Former Companies

The future for portable roll former companies looks promising as industries continue to seek efficient, cost-effective tools. These companies are likely to expand their market reach into emerging economies where construction and manufacturing are on the rise. Furthermore, as technology progresses, we can expect to see more developments in machine intelligence and automation, paving the way for smarter, more intuitive equipment.

In conclusion, portable roll former companies are playing a pivotal role in the evolution of the metal fabrication industry. By providing flexible, cost-effective, and high-quality solutions, they are revolutionizing how manufacturers approach production. As innovations continue to unfold, these companies will undoubtedly shape the future of industrial manufacturing, driving greater efficiency and sustainability across various sectors.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025