Portable Roll Forming Solutions for Efficient On-Site Metal Fabrication and Construction Needs

Portable Roll Former Company Revolutionizing Metal Forming

The advent of portable roll former technology has revolutionized the way metal is processed and formed in various industries. For both skilled tradespeople and large-scale manufacturers, portable roll formers have become essential tools that enhance efficiency, productivity, and adaptability in the field. This article explores the significance of portable roll former companies, their technology, and the myriad benefits they provide to their users.

What is a Portable Roll Former?

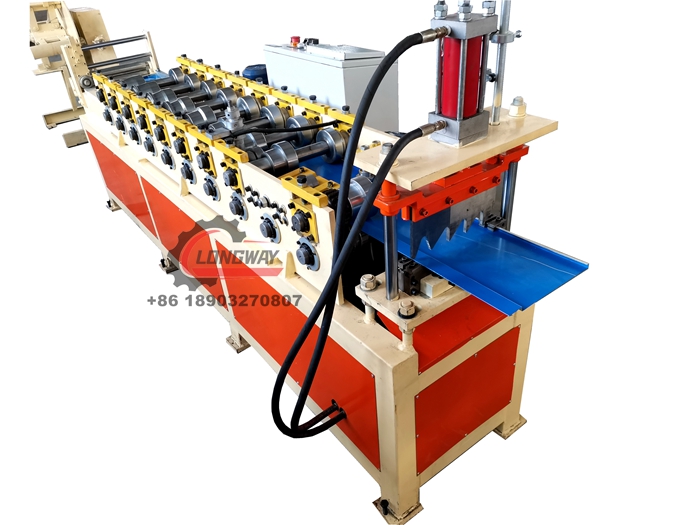

A portable roll former is a machine that shapes metal sheets into specific profiles by passing them through a series of rollers. Unlike traditional roll forming machines, which are typically large and stationary, portable roll formers are designed to be lightweight and easily transportable. This means that they can be taken directly to job sites, allowing for on-the-spot metal forming and reducing the need for costly transportation of materials.

The Role of Portable Roll Former Companies

Companies that specialize in portable roll forming provide a wide range of machines tailored for various applications, from roofing and siding to custom metal fabrication. These businesses also offer comprehensive support services, including training, maintenance, and repair, ensuring that customers can make the most out of their equipment.

Portable roll former companies pride themselves on innovation. They continually adapt and enhance their machines to meet the evolving demands of the market and the specific needs of their clients. This commitment to advancement has led to the incorporation of technologies such as computer numerical control (CNC) systems, which improve precision and ease of operation.

Advantages of Using Portable Roll Formers

1. On-Site Production One of the most significant benefits of portable roll forming is the ability to produce metal components right at the job site. This capability saves time, eliminates transportation costs, and reduces material waste. For example, instead of ordering pre-formed sheets or components, contractors can form exactly what they need when they need it.

portable roll former company

2. Customization Portable roll formers offer immense flexibility. They allow users to create custom profiles based on project specifications. Whether a builder needs unique roofing panels or specific trim pieces, these machines can be adjusted to achieve the exact shape and size needed.

3. Cost-Effectiveness By reducing overhead costs associated with transportation and minimizing waste, portable roll formers can lead to significant savings. Additionally, these machines often require less workforce to operate compared to traditional large-scale machines, further cutting down on labor costs.

4. Versatility Portable roll formers are ideal for a wide range of industries, including construction, agricultural, automotive, and manufacturing. Their versatility allows them to be used for multiple applications, from creating standing seam roofs to structural components for various builds.

5. Ease of Use Modern portable roll formers are designed with user-friendliness in mind. With intuitive controls and simplistically designed setups, operators can quickly learn how to utilize these machines, further enhancing productivity on site.

6. Durability Most portable roll forming machines are built to withstand the rigors of job site conditions. Constructed from high-quality materials, they are engineered to perform reliably, ensuring that metal components can be produced consistently without interruptions.

Conclusion

Portable roll former companies are leading the charge in transforming the metal forming industry. By providing innovative, efficient, and easy-to-use equipment, they empower businesses to take control of their metal fabrication needs with unmatched flexibility and cost savings. As industries continue to evolve, the role of portable roll forming technology will undoubtedly grow, solidifying its importance in manufacturing processes worldwide.

In a fast-paced world where every second counts, portable roll formers represent a pivotal shift towards more agile production methods. For companies looking to enhance their capabilities, investing in a portable roll forming solution is not just an option; it’s a necessity for staying competitive in today’s market. As technology advances and customer needs change, the future of portable roll forming looks promising, heralding new possibilities for innovation and efficiency in metal fabrication.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025